Supply Chain and Logistics Management

Techniques for handling Vendor item arrival errors in Dynamics 365 Finance and Supply Chain

Techniques for handling Vendor Item Arrival Errors in D365

Vendor Scorecard | Master Planning | Production Line | Safety Stock | Load Building

What is a Vendor?

So, the first question is: What is a vendor? A vendor is a person or organization that offers a product or service to another company. Finding a dependable and cost-effective vendor supplier is critical to your company’s success.

The general conditions you negotiate with your vendor should be based on the following:

- The method by which you pay them – bank draft, bank-paid commercial bill, foreign currency

- Probable expenses – administration, taxes, transportation management, general payments, and transactions

- Potential hazards – late payment to supplier, late shipments or defective, late, or undelivered products

SUMMARY

Your company’s success depends on finding a reputable and cost-effective vendor provider. The term “vendor” refers to a person or corporation that sells goods or services to another business. You should base the terms of your agreement with your vendor on how you intend to pay them.

Your Vendor Should Provide Excellent Service

Select vendors that provide high-quality service and can fulfill your particular requirements to guarantee a fruitful working relationship. You can verify the quality of a prospective supplier via a variety of national and international certification organizations. The International Organization for Standardization (ISO 9000) accreditation is the most generally recognized and accepted of them. ISO 9000 is a collection of quality management standards used and recognized by thousands of businesses in over 100 countries across the world. Its mission is to promote and ease international commerce by establishing a single set of internationally recognized and respected standards. On the website of the International Organization for Standardization (ISO), you may learn more about ISO 9000.

SUMMARY

Various national and international certification bodies may be used to check a potential supplier’s quality. Generally, ISO 9000 certification is recognized and acknowledged as the industry standard. With a single set of globally recognized and accepted norms, it seeks to encourage and simplify international trade.

Specific Requirements for Selecting a Vendor

Select vendors that can fulfill your particular requirements.

Develop positive vendor connections

It pays to put effort into cultivating positive connections with your main vendor. Your company will benefit if you can save money or enhance the quality of the products or services of your purchase orders from your vendors.

Suggestions for Working with Your Vendors

When dealing with your vendor, keep the following in mind:

- Meet your contacts in person and see how they do business. Understanding how your supplier operates can help you see how it may benefit your company.

- Meet the individuals who will be in charge of your account and make sure you can reach them easily.

- Inquire about their goals for growth or development. Will this have an impact on the products or services they provide you?

- Assist your suppliers by making orders on time, keeping deadlines clear, and paying on time. See the page in this handbook on how you may assist your major suppliers for further information.

- Keep your eyes peeled for any possibilities you may send along to them; in a strong customer-supplier relationship, they’ll reciprocate.

- Emphasize the importance of your company to your suppliers, and they will work harder for you. If you pledge to use them exclusively, certain providers may give you greater rates.

- Don’t pass up chances that come your way. Monitor the discounts provided by rival providers to keep your choices open.

SUMMARY

Get to know your vendors and learn about their business practices. To help your suppliers, be sure to place orders on time, be explicit about deadlines, and make timely payments. Keep an eye out for competitor offers to help you save money. If you stress to your suppliers how important your business is, they will work more for you.

5 KPIs Every Inventory Manager Should Track

| KPI | Description | Advantage |

| Demand Forecast Accuracy | Actual forecast accuracy is defined as the ratio of forecast to actual sales. | It also allows for easier aggregation when taking into account an overall average across SKUs. |

| Lead Time (Order Cycle Time) | Lead time, or order cycle time, is a KPI that gives you a snapshot of how efficiently your order processing is working. | Tracking this metric can help nail down inefficiencies in the production line, warehousing, or logistics. |

| Shrinkage | Shrinkage is defined as the difference between actual stock on hand and what’s showing on paper. | The shrinkage lets you know how much extra stock you need to be producing in order to maintain orders and meet demand without coming up short. |

| Storage Costs | Often described as a percentage of the value of all available stock, storage costs are calculated on the total cost of warehousing that stock. The calculation generally includes these factors:

|

This metric is important to have on hand when determining the bottom line boost you can achieve by streamlining existing processes and working to eliminate the need for storing merchandise for extended periods of time. |

| Perfect Order Performance | This gives a snapshot of the overall health of the entire end-to-end supply chain such as:

|

it’s adjustable based on your specific needs. it also has the power to cut through information silos and is one of the simplest ways we know of to get an overall picture of your supply chain health. |

How can you assist your important vendors?

It’s in everyone’s best interests if you can get the most out of your main supplier relationships. Every vendor needs special attention since their performance may be critical to your company’s success.

Here are some suggestions on how you may assist your major suppliers:

- Coordinate your and their production schedules.

- Talk about methods to cut overall expenses by changing the amount or timing of orders/contracts.

- Think about what other goods or services your provider could offer.

- Keep them informed about strategic changes or new goods early on; this will help them adjust to the changes.

- Examine how effectively you predict sales and prepare to fulfill your supply requirements. You can create realistic sales strategies and fine-tune shared sales projections and schedules by sharing the findings of this research with your suppliers.

- Control and monitor the purchasing of products and services from suppliers using a purchase order system; this simplifies internal financial controls and eliminates specification ambiguities at the supplier’s end. Check out our inventory and stock management guide.

- Pay your bills on time. Late payments may damage your connection with the provider and may result in future terms that are less favorable. You should ideally have a payment policy in place that commits your company to pay undisputed invoices on time, with a copy provided to your suppliers.

- Technology, particularly Internet-based communications, may assist you in developing and maintaining positive relationships with your suppliers in a variety of ways.

SUMMARY

Face-to-face meetings with your suppliers are the best way to learn about their business practises. Don’t forget to help your suppliers by placing orders on time and paying them on time as well. Keep an eye out for discounts from competing service providers to ensure you have a variety of options. Suppliers will work harder for you if you make your business important to them.

Improve efficiency by using technology

You can work more closely with your vendor thanks to technology, which enables you to share strategies, predictions, and customer data.

It is simpler for you to:

- Analyze real-time information about sales, orders, or market trends by sharing such information with your suppliers.

- Be able to predict and respond promptly to changes in demand.

- Increase efficiency – precise stock information means you’ll only order what you need.

- E-collaboration with your vendor, such as utilizing email and sharing spreadsheets, may be easy, but exchanging information in “real-time” provides the most advantages. This necessitates the use of more advanced technologies, such as the following:

- Inventory planning, planning transportation, or forecasting systems – utilize your inventory data to anticipate market demand.

- Enterprise resource planning (ERP) systems – can organize and schedule your whole company.

- Online analytical processing systems – can analyze previous sales performances and compare predictions from various vendors. Orders may be placed and monitored automatically, and the supplier will issue an invoice automatically if your order and buying systems are linked to those of your suppliers.

Make sure your data, as well as the data of your suppliers, is secured while exchanging information.

SUMMARY

While working with your vendor through e-collaboration is convenient, sharing information in “real-time” offers the most benefits. Inventory and forecasting systems, for example, are required because of this. If your order and purchasing systems are connected to those of your suppliers, orders may be made and tracked automatically, and the supplier will automatically send an invoice.

Examine the performance of your suppliers

Regularly reviewing the performance of your suppliers is a smart practice. You can guarantee you’re receiving the greatest price by asking the following crucial questions:

- Cost – are you receiving the best deal possible? Is there a bulk discount or other advantageous conditions available from your supplier?

- Satisfaction with the quality of your goods – are you happy with the quality of your supplies?

- Innovation – do your suppliers keep you up to date on new goods and services that may benefit your company?

- On-time delivery – are your vendors on time? Are the goods in excellent working order when they arrive?

- Account management – how fast do your suppliers react to any orders or inquiries you send them?

You’ll have to evaluate your performance as well. Paying your suppliers late, for example, will not encourage them to maintain excellent standards.

SUMMARY

The greatest advantages come from sharing information in “real-time” with your vendor. If your order and buying systems are linked to those of your suppliers, orders may be placed and monitored automatically – and suppliers will give you invoices for products and services automatically.

VENDORS BEING TERMINATED

A contract with a vendor may be terminated for a variety of reasons. They may, for example, frequently fail to supply you with services or products that suit your needs, or you may discover a cheaper or more dependable provider elsewhere. Check the contract to determine if there are any consequences for ending the contract early. When drafting the contract, you should aim to include an exit provision that reduces the amount you have to pay. Otherwise, the penalties may be so severe that you are essentially tied to that one vendor. Your company may suffer if your supplier’s quality and efficacy deteriorate. You’ll encounter operational challenges as well as financial ones when switching vendors. When you move to a new supplier with different procedures or systems, your company may be disrupted.

Ensure that your current provider provides you with all of the information you need to make the transfer easier. Negotiate, if feasible, for your new supplier to be in charge of the transition.

SUMMARY

There are many reasons to end a contract with a provider. Ensure an exit provision lowers the amount you must pay when creating the contract. If at all possible, negotiate for the transfer to be handled by your new provider.

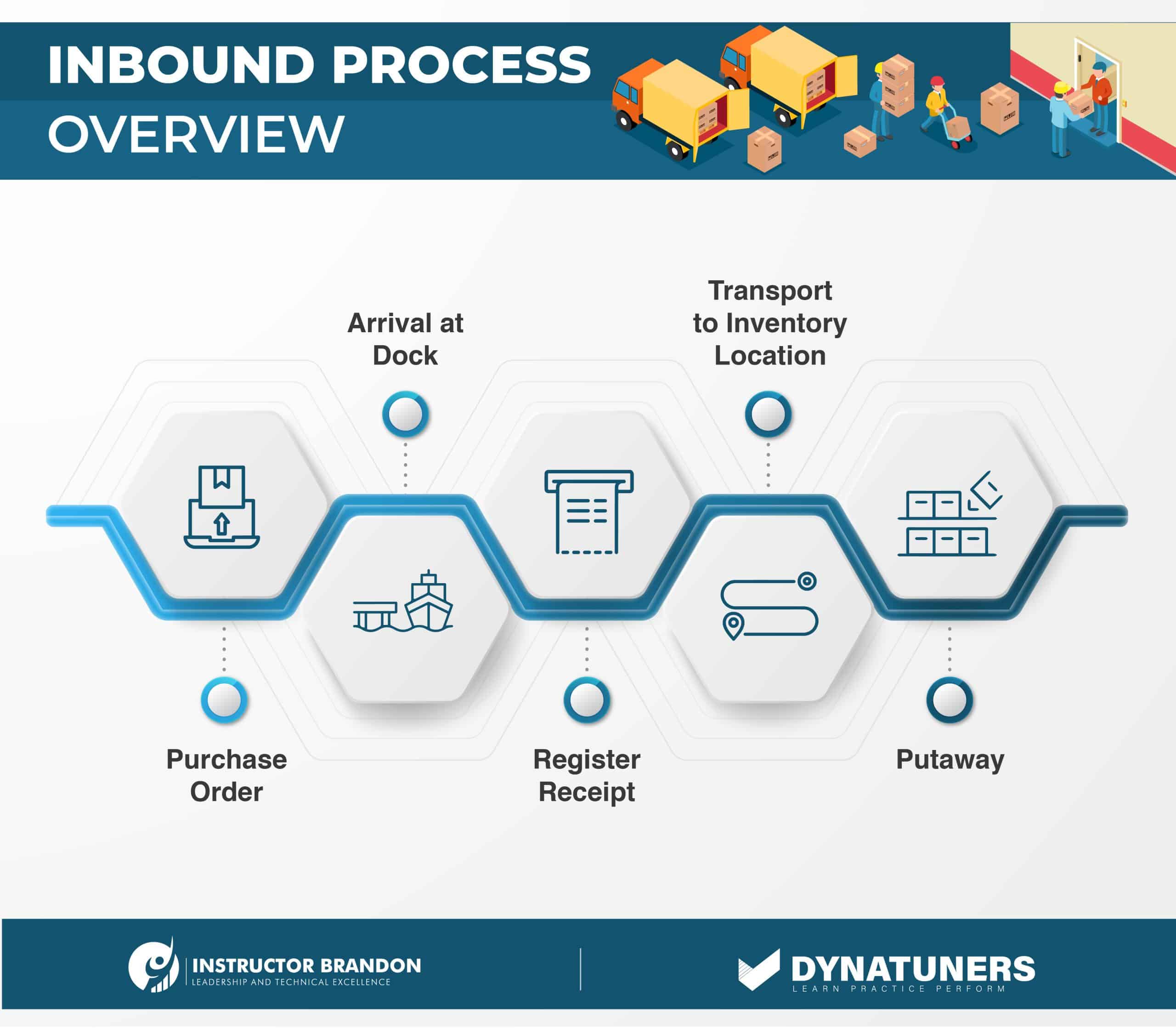

Warehouse Inbound Process Flow

The “Inbound process” in logistics is the most important element of any Supply Chain Management System’s performance. A well-functioning warehouse inbound process flow is critical to your company’s efficiency. Working on scheduling deliveries, maintaining inventory, storage needs, and handling are all part of your warehouse’s incoming process flow. It also considers the orders of consumers by conducting frequent inventory checks.

SUMMARY

The “Inbound process” is critical to the success of any Supply Chain Management System. Efficiency depends on a smooth warehouse incoming process flow. It manages delivery, inventory, storage, and handling.

Common Delays in the Supply Chain

Suppliers and consumers alike are affected by supply chain disruptions. When this occurs, we don’t always think about what’s going on in various parts of the supply chain to cause the delays. Knowing where these circumstances arise, on the other hand, may help with predicting and avoid ineffective reactive decision-making.

Delays in manufacturing or production

Delays from manufacturers are unavoidable. Human mistakes, such as contamination or poor demand forecasts, may quickly disrupt production. Even if the manufacturing crew is flawless, there will be delays from time to time. Production necessitates assembly, which necessitates the use of materials and equipment. So what if the equipment isn’t working properly? What if tariffs suddenly make materials less accessible?

Manufacturers are subject to a plethora of global externalities that may affect manufacturing orders. These errors often have a domino effect in the supply chain, affecting all subsequent shipping operations. That implies that throughout the phases leading up to the final delivery, every supplier must be ready to respond quickly to fulfill the lead times.

Delays in Warehousing

Warehousing is used by suppliers to store, fulfill, and transport orders and each of these services has its own set of activities. When management lacks innovative tactics in warehouse works or operations, warehousing delays may occur. It requires a competent staff to guarantee that shipments arrive on time, inventory is correct, and orders are fulfilled quickly.

A company’s merchandise isn’t always kept in a warehouse. If orders are damaged or drivers aren’t on time, shipments may be delayed during transportation services like cross-docking.

In most cases, technology is to blame for warehousing inefficiencies. Without industry-standard cloud-based technology that provides for transparency into operations and efficiency, mistakes are certain to arise.

Delays in shipping

It’s up to the carriers and freight forwarders to fulfill the order at this stage. Both suppliers and customers depend on collaborative order management to avoid frequent last-mile delivery problems. Transportation chaos, like manufacturing and warehousing delays, is unavoidable at times. Disruptions are sometimes caused by poor communication, time management, and decision making, in addition to factors, we can’t control like weather, traffic, and mechanical

SUMMARY

Knowing where these situations occur may assist with anticipating and avoiding reactive decision-making that is unproductive. Contamination or incorrect demand estimates caused by humans may rapidly interrupt manufacturing. Transport services like cross-docking may cause delays for shipments if items are damaged or drivers are late. Errors are likely to occur without the use of industry-standard cloud-based technology that offers visibility into operations and efficiency.

Common Issues with Adjustment of Inventories

On-time delivery is something you rely on from your vendors. If your order is late, it may cause a chain reaction that jeopardizes the success of your project. You’re paying the production crew for work they can’t do until the cargo comes. If it’s late, your timetable is pushed back, which has an impact on delivery to your client, who is dealing with their deadlines. If you can’t meet your customers’ deadlines, you may jeopardize future contracts. When dealing with shipments in incoming operations, there may be a variety of causes for delays, including:

- Shipments with insufficient inventory

- Incorrect inventory items sent

- Visibility of disconnected systems

- Shipments that are late – visibility

- Demand forecasting that isn’t accurate

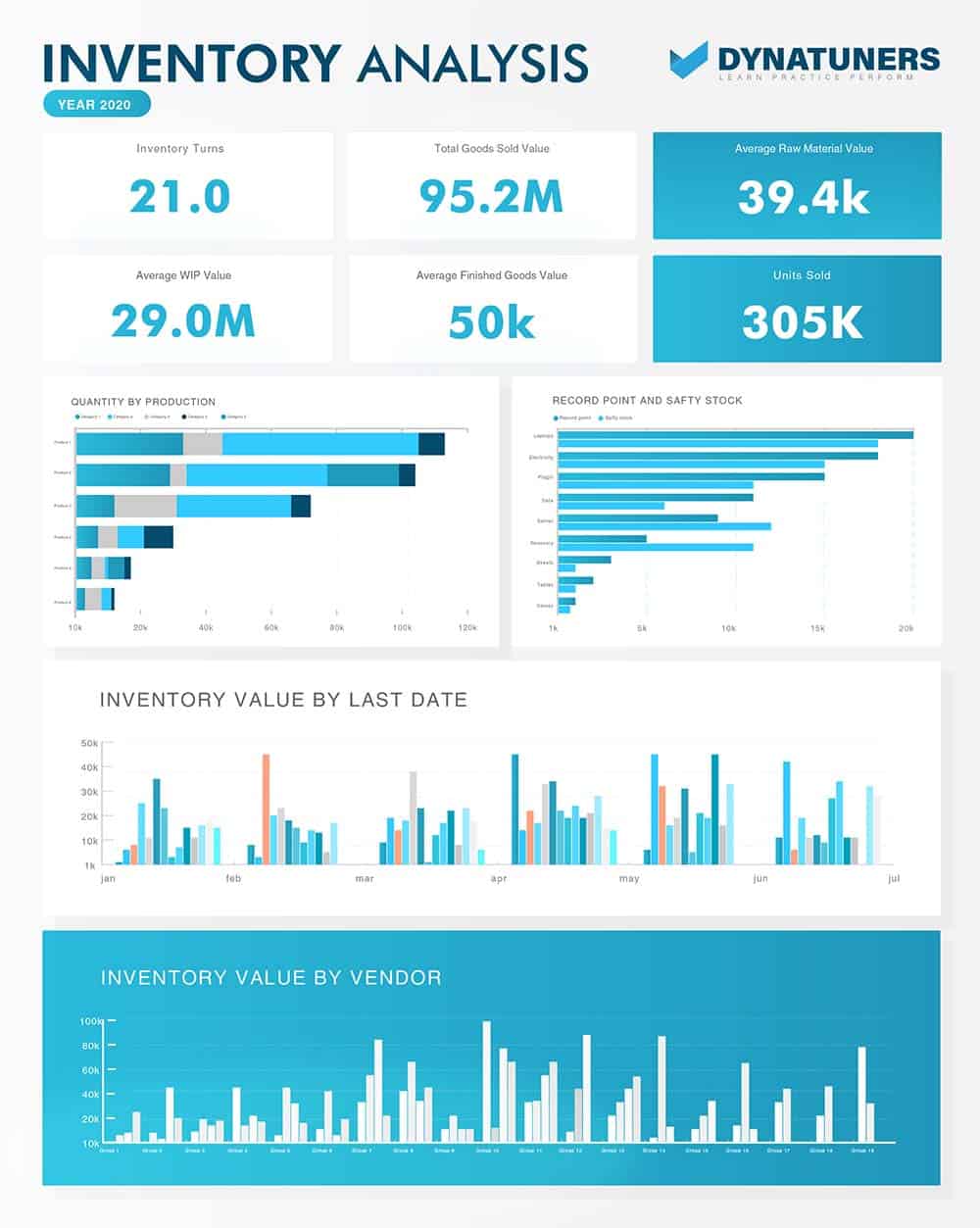

Key Performance Indicators (KPIs)

Supply chain choices based on uncertainty presume that you will not be correct on every prediction you make. The idea is to evaluate each option by concentrating on key performance indicators (KPIs) that indicate how resilient your supply chain is to uncertainty and then evaluating the likelihood of success in the resultant supply chain choices. The receiving procedure is the most common source of inventory issues for most distributors.

- Your seller may shortchange you.

- Vendor may give you additional goods.

- Your seller may provide the incorrect goods.

- The personnel who receive the goods into the warehouse may count them incorrectly.

- The receiving procedure is the most common source of inventory issues for most distributors.

You must implement a check and balance system for warehouse operations and back-office data input to minimize mistakes. They must check a “verified” field in the accounting system once they have double-counted every item and validated it against the original piece of paper. This validated record is then printed, stapled to the original, and filed away. Need any help with improving visibility in your supply chain? We have customized reports and dashboards in Dynamics 365 for several years and understand the challenges associated with it. Please contact us to learn more about our Dynamics 365 reporting solutions.

SUMMARY

Your suppliers’ on-time delivery is something you can count on. If your order does not arrive on time, it may set off a series of events that could threaten the success of your project. Key performance indicators (KPIs) are used to measure how robust your supply chain is to unpredictability. This allows you to compare different options side-by-by-side.

Arrivals Overview Process in D365

The Arrival Overview page displays a list of all goods that are anticipated to arrive. It also displays arrivals that may be set up using the overview. Because our blog article is about incoming shipments and arrivals of items/goods, readers may receive a quick summary of the current tasks, as well as an approximate estimate of numbers, volume, weight, and various order kinds. Because of the uncertainties in the supply chain, the Arrival overview page also includes functions like locating the matching receipt order, registering receipts, finding the right arrival journal reference and identifying journals that are ready for a product receipt update.

To read more about issues with supply chain processes, visit our Dynamics 365 blogs.

SUMMARY

The Arrival Overview page displays a list of all goods that are anticipated to arrive. It also shows arrivals that may be set up using the overview. Because of the uncertainties in the supply chain, the page also includes functions like registering receipts and finding the correct arrival journal reference.

Microsoft Dynamics 365 and Inventory Adjustments

Microsoft Dynamics 365 SCM has undoubtedly provided many benefits to businesses of all shapes and sizes via its Inventory Closing and Adjustment capabilities. As a result, you won’t be as competitive if you don’t have enough monitoring or if your inventory tracking system fails. As a result, catching up to the rest of your competitors, both locally and internationally, will be a pipe dream. However, as the corporate sector evolves, so must the tools used by workers. Microsoft understands this subject better than anyone else in the market, which is why they can ensure that their business solutions stay at the cutting edge of technology.

To achieve high-performance levels for a supply chain, real-time insights on the company’s resources, current inventory, warehousing procedures, manufacturing, and distribution were crucial. As a result, Microsoft Dynamics 365 Supply Chain Management provides this information while integrating operations across all major sectors, from receiving products through shipping and distribution. Moreover, we’ve found that the improvements in reporting and Power BI within Dynamics 365 allow for much easier visibility into the supply chain

SUMMARY

In order to remain on top of their game, businesses use Microsoft Dynamics 365 Supply Chain Management (SCM). It is critical to have real-time information on a company’s resources, current inventory, warehousing processes, production, and distribution in order to achieve high levels of performance in the supply chain.

How do I Use Supply Chain Inventory Adjustments in Microsoft Dynamics 365?

Inventory adjustments are used in our company’s inventory reports to account for unforeseen events such as items being damaged, stock transfers, and product returns.

All inventory changes are done in journals in dynamics. We go over to the item journal to make the necessary adjustments.

Step-by-Step Process in Microsoft Dynamics 365

Scenario:

We will be using the Midrange Speaker item to adjust its inventory. As shown below its previously available physical quantity is 9.

We will use the inventory adjustment journal to update its quantity to a total of available physical of 239 units.

STEPS:

Step 1

From the navigation pane head over to the Inventory Management Module

Step 2

Go to the Journal Entries menu and then to the items submenu and select Inventory Adjustment

Step 3

Click on New to add a new journal that would define what kind of inventory adjustment is being made for which product.

Step 4

Now we have to specify the site and warehouse from where the adjustments are being made for the item and then click on OK.

Step 5

Once the journal has been created below shown form is opened up.

Here we have to add the item in the lines and view and specify the item number that will be using this journal.

Step 6

Once that is done, we have to edit the quantity column with the desired quantity that we want to adjust

If positive inventory adjustment is required just enter a positive number

If negative inventory adjustment is required just enter a number with a negative sign.

Here we gave the item a quantity of value

Step 7

Now we simply click on Validate to make sure that the journal is OK to post.

Click on OK to validate the journal.

Step 8

Once the journal is validated, we then click on post.

Click on OK to post the journal.

The Infolog is shown that tells us about the successful posting of the adjustment journal.

Step 9

Now to check the adjusted inventory of the item Midrange Speaker we go into the Inventory Management module then into the Inquiries and Reports menu and click on On-Hand List.

Step 10

Now we can see the item Midrange Speaker has an increased inventory value as shown below.

SUMMARY

Follow the instruction as per the steps and you will be able to see increased value of item Midrange Speaker.

Simple ways to handle Vendor Inventory Errors and Adjustments

Product-selling companies rely significantly on precise inventory management and real-time operational insight to be profitable. When inventory adjustments are required often, warehouses and inventory are not being handled effectively. Businesses that manage inventory using manual or disconnected methods are often plagued by mistakes and errors, resulting in a plethora of financial inconsistencies. Inventory changes may be expensive for a company since they obscure actual prices of products, profit margins, and bottom lines. While not all inventory changes can be avoided, with the proper tools, the frequency may be reduced.

SUMMARY

Product-selling companies rely significantly on precise inventory management to be profitable. Mistakes and errors often plague businesses that manage inventory using manual or disconnected methods. While not all inventory changes can be avoided, the frequency may be reduced with the proper tools.

Adjusting Inventory: Performing Regular Cycle Counts

Cycle counts must be performed regularly to ensure inventory accuracy. Cycle counts assist guarantee inventory advertised as available is accessible by rapidly identifying inventory inconsistencies caused by damaged, lost, miscounted, or stolen goods. Inventory is tallied incrementally in Activate, with all inventory being recorded in parts over time rather than all at once. When the counts are performed, what SKUs are tallied, and how frequently the procedure is done are all options available to a company. Cycle counts are simplified and extremely precise with the inclusion of barcode software, as opposed to conventional counting and tracking techniques, which are prone to human mistakes – and with faults comes the need to modify an inventory.

SUMMARY

Cycle counts ensure inventory advertised as available is accessible by rapidly identifying inconsistencies caused by damaged, lost, miscounted, or stolen goods. Inventory is tallied incrementally in Cycle Counts, with all inventory being recorded in parts over time rather than all at once.

Implement better visibility through Order Accuracy Rate Tracking

The proportion of all ecommerce orders that are completed and delivered to their ultimate destination without mistake, such as an erroneous item selection or unit amount, is known as order accuracy. Order accuracy is a crucial statistic to monitor since it has a significant effect on customer satisfaction.

Delivering the incorrect order not only ruins the unboxing experience, but it may also be expensive and time-consuming since you’ll have to invest more time and effort to correct it.

Order accuracy is a crucial statistic that should be tracked and improved regularly. To figure it out, take the number of correct orders you’ve completed, divide it by the total number of orders you’ve completed, and multiply the result by 100.

(Total orders fulfilled correctly / Total orders fulfilled) * 100 = Order accuracy rate

For Example

Let’s have a look at an example. If you complete 100 orders and just two of them are incorrect, your order accuracy rate is 98 percent. Take a look at the following calculation:

(98 / 100) * 100 = Order Accuracy Rate

98 percent accuracy rate on orders

Many moving components and human involvement are involved in retail fulfillment. Although achieving a 100 percent order accuracy rate is not always feasible, you should strive for as near to 100 percent as possible.

The order accuracy percentage for most successful direct-to-consumer (DTC) brands is between 96 and 98 percent. If your company falls into that category, increasing your accuracy rate may offer you a competitive advantage.

If your company’s order accuracy rate is less than 95%, you’re at a significant disadvantage and should work to improve it so that consumers won’t be hesitant to buy from you again.

How to improve your Delivery Order Accuracy?

Your delivery order accuracy improves when you deliver the precise item at the correct date, time, and place based on the order request. It goes lower every time you have failed deliveries, returns, incorrect orders, or damaged shipments. These mistakes may arise at any point throughout the delivery process due to inaccuracies. This includes the following:

- Forecasting inventory

- Purchasing products

- Order requests for invoicing

- Organizing depots and pick-up locations

- Drop-off and transportation

Knowing where these mistakes happen may help you enhance the quality of your satisfaction. As a result, the customer experience improves. Tracking and monitoring order accuracy also aids in the detection and correction of these issues, preventing them from reoccurring.

SUMMARY

The proportion of all ecommerce orders that are completed and delivered without mistake is known as order accuracy. Order accuracy is a crucial statistic to monitor since it has a significant effect on customer satisfaction. The order accuracy percentage for most successful direct-to-consumer brands is between 96 and 98 percent. If your company falls into that category, increasing your accuracy rate may offer you a competitive advantage.

Power BI dashboards in Intelligent Order Management

Dynamics 365 Intelligent Order Management offers a collection of dashboards built on Microsoft Power BI technologies that are integrated into the user experience. The Power BI dashboards provide a longer-term view of the order and fulfillment data flowing through the app.

Your data may be seen in Power BI-based dashboards with the Intelligent Order Management license. Do you need assistance in enhancing supply chain visibility? We’ve been customizing reports and dashboards in Dynamics 365 for several years and are familiar with the difficulties. To learn more about our Dynamics 365 reporting solutions, please contact us.

SUMMARY

Dynamics 365 Intelligent Order Management offers a collection of dashboards built on Microsoft Power BI technologies. Power BI dashboards provide a longer-term view of the order and fulfillment data flowing through the app. Do you need assistance in enhancing supply chain visibility? Contact us to learn more about our Dynamics 365 reporting solutions.

Adjusting Inventory: Making Sure the Receiving Process Is Accurate

The receiving process is prone to vendor inventory errors, with goods being miscounted, the right quantity of products being assumed, and broken or rotten inventory being missed until it’s put on the shelves. Inventory receiving may become a considerably simpler, more efficient, and exact job with the integration of barcoding software and Activate, leading to fewer adjustments. Warehouse optimization, such as bin placements and barcodes, and tools to control deviations immediately on the spot, eliminates the need to change inventory manually based on wrong numbers.

SUMMARY

The receiving process is prone to errors, with goods being miscounted and the correct quantity assumed. The need for changing inventory based on incorrect figures or damaged products is reduced sooner, thanks to optimized bin placements.

At Instructor Brandon | Dynatuners, we are always looking for new ways to help you stay competitive while still meeting your Microsoft Dynamics 365 needs. Our products and services are based on well-established processes, extensive industry experience, and in-depth product knowledge. If you want to speak with one of our technical solutions experts about how to reach your process optimization goals, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What are three things that an inventory correction may change? ” answer-0=”There are three reasons why inventory changes may be necessary. The item’s value is incorrect, the quantity is incorrect, or both the value and the quantity are incorrect. ” image-0=”” headline-1=”h2″ question-1=”What are the most frequent causes of shipping delays? ” answer-1=”On a regular basis, shipping delays and receiving damaged products occur. The most frequent causes of delays are firstly, lack of visibility across the supply chain is critical for ensuring a safe and timely transport from one end to the other. Without it, businesses risk becoming victims of many inefficiencies, which may result in delays, damage, or the loss of goods. Secondly, inadequate technology: For delivery businesses, old software or ancient hardware presents significant challenges since it restricts their capacity to incorporate new technologies and access capabilities that assist reduce shipping delays. Moreover, lost Packages are Arguably the most aggravating experience a client can have begins with the inquiry, “Where is my package?” There are many reasons, including a simple misplacement, a broken mailing label, or an unintentional removal. Weather Conditions also act as major delays. Safety must always be a top concern for all delivery companies. Weather-related road closures always result in delays owing to sluggish transits. High-volume shipments further do cause delays. If a delivery business does not have an appropriate software system, a sudden or unexpected rise in shipment delivery quantities may overwhelm it. ” image-1=”” headline-2=”h2″ question-2=”Is it essential to anticipate demand for inventory planning? ” answer-2=”Demand forecasting aids in the reduction of inventory carrying costs, the planning of marketing expenditures, future headcount, manufacturing and inventory requirements, and even the development of new goods. ” image-2=”” count=”3″ html=”true” css_class=””]

2263

2263