Supply Chain and Logistics Management

How to update Arrival information of products in Dynamics 365 and improve Warehouse Forecasting

Demand Forecasting & Warehouse Management in Dynamics 365

Demand Forecasting | Sales Order | Master Planning | Inventory Forecast | Demand Planners

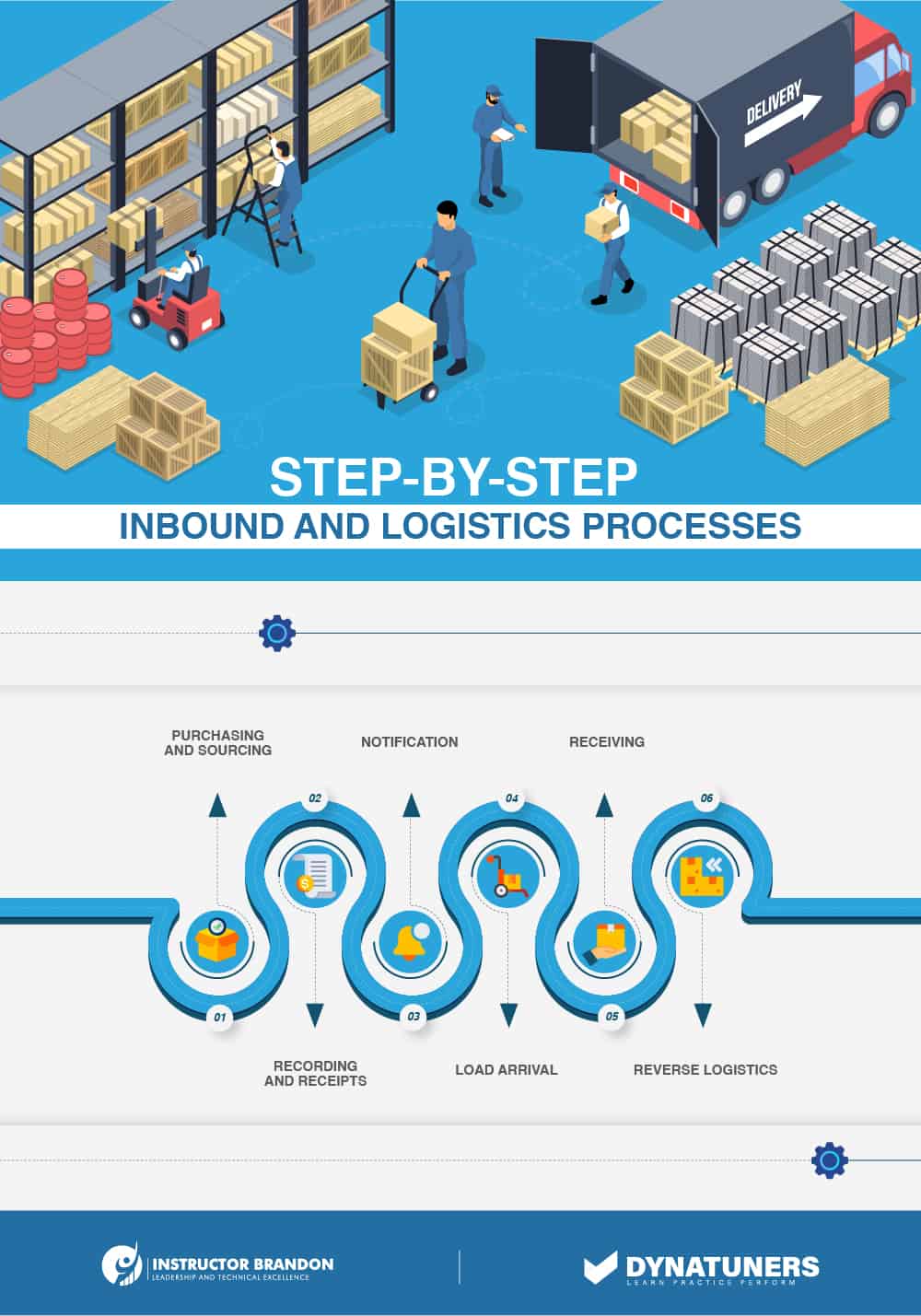

WHAT ARE INBOUND ORDERS?

Inbound orders entail receiving items from the manufacturing facility or product creator in the context of a warehouse that fulfills direct-to-consumer orders. Stock might be in the shape of raw materials, ready-to-ship goods, or packing supplies, as you are aware. Depending on the retailer’s business model, the manufacturers can transport products to a warehouse, a third-party logistics and fulfillment center, or a brick-and-mortar shop.

SUMMARY

Stock might be in the shape of raw materials, ready-to-ship goods, or packing supplies. Depending on the retailer’s business model, products can be transported to a warehouse, third-party logistics and fulfilment center, or a brick-and-mortar shop.

WHAT HAPPENS DURING INBOUND LOGISTICS?

The logistics network that brings goods and materials into your company is referred to as inbound. You’ll need an inbound logistics network if you’re transporting, storing, and delivering products from suppliers to your warehouse. There are a few considerations to make sure your import logistics run well. In specific, manufacturing businesses need raw materials to create certain products, therefore, you must ensure that you have a constant supply that meets demand. You don’t want a large number of raw materials to arrive simultaneously, taking up valuable storage space in your warehouse. Because of this, inbound logistics’ typical phases are as follows:

-

Receipts and Taking Notes

To ensure that each stage of the process is correctly performed and communicated, receipts will help supply chain management. Receipts often include a list of what was purchased along with the price, quantity, and measurement units. Lot numbers, manufacture and expiry dates, serial numbers, inventory receipt statuses, receipt status regulations, and the instant availability of goods for cross-docking and backorders are some of the components that must be verified during this process. Several supply chain companies utilize an automated pre-receipt notification system to transmit and receive data before it reaches the warehouse or distribution hub. Data entry time will be reduced, which will improve incoming procedures.

-

Arrivals of the Load

Following the loading of pre-receipts into warehouse management systems, the receiving process will begin accordingly. Because the possibility for human mistake has been removed, this early incoming procedure will help supply chain businesses be more successful. The warehouse manager will know exactly where to prepare for unloading when the shipment arrives.

To begin the receiving process and to commence real-time reporting, receipts will be given to warehouse managers and coordinators. Logistics and transportation firms can verify that all warehouse personnel are at the proper dock door and unloading the correct items using automated systems. This is based on the information on the delivery receipts. Stockroom supervisors get to work on the detailed receiving phase only when receiving and loading procedures have been successfully completed.

-

Licensing Plate Tracking

It’s just as essential to have complete control over your moving goods as it is to have complete control over your storage and warehousing operations. Because WMS systems enable the management of the whole incoming logistics process, logistics firms have begun tracking their license plate numbers.

-

Closing Receipts

The procedure of updating that the trailer or carrier has been emptied is the final stage in the incoming logistics process. This procedure used to be done by hand in earlier systems, but modern systems have automated it. This phase also allows for reviews and exceptions since it may be changed in real-time. This method also enables ports to be designated as open for future lead shipments or receipts immediately after receipts and other information has been provided in real-time.

INBOUND PLANNING FOR DEMAND FORECASTING

In order to minimize the cost of products supplied, many businesses monitor their inbound planning and procurement expenses. Better visibility of inventories and products in transit, as well as improved transportation and reduced labor expenses, all help to decrease costs.

When a purchase order or transfer order is created, a warehouse has insight into incoming inventory. The purchase order is owned by a merchandising or ordering system. A transfer order is started either as an inter-warehouse transfer or as a transfer after the production process is finished.

This is accomplished by tracking the purchase order from the individual participant to the destination.

SUMMARY

A purchase order or transfer order is a warehouse’s insight into incoming inventory. The purchase order is owned by a merchandising or ordering system. Better visibility of inventories and products in transit, as well as improved transportation and reduced labor expenses, all help to decrease costs.

INBOUND EXECUTION

The completion of the inbound planning process, which includes receiving and storing goods, is known as inbound execution. One of the most important variables that directly affect a warehouse’s throughput is inbound execution. The time it takes to put away, refill, and pick inventory is strongly influenced by where and how inventory is kept in a warehouse. The kind of inventory received, how the inventory is received, and the equipment used to collect and put away goods all take up a considerable amount of time in warehouse architecture and setup.

In a warehouse, the receiving process begins with the acceptance of products from the transporter, followed by the physical process of inventory checking and reception. The acceptance procedure involves comparing the quantity of items (cases or pallets) to the carrier’s bill of lading or packing slip. If an ASN is not available for the cargo received, the contents are verified using a preprinted page. A receiving sorter is used to finish the process of receiving inventory into a warehouse using a Radio Frequency (RF) Mobile Terminal, console, or MHE.

Pre-Packaging Procedures

Pre-packaging procedures must be completed for certain goods received at a warehouse before they can be stored away. Screws, for example, are received in big boxes or sacks and packed into suitable inventory UOM packs before being stored away in the components business. These pre-packaging operations need allocating a separate warehouse site. The ability to automate these processes depending on the SKU received lowers manpower requirements considerably.

The software has a lot of features that make it easy to manage the inventory execution process. It also gives you full insight into the supply chain’s individual shipments. This insight is further enhanced by monitoring the acceptance of goods from a carrier.

The system also allows for the redirection of incoming inventory to the proper location based on quality profiles, cross-dock needs, or put away preferences. It also enables you to model a warehouse separately from the rest of the warehouses, depending on its layout.

The data collected throughout the receiving process is accessible via consoles for auditing and monitoring reasons. A shipment may be marked as received at the package level using the pre-receipt procedure.

Are you ready to take the next step in your career? Join us in our offered courses to get unique hands-on experience in Dynamics courses.

SUMMARY

The time it takes to put away, refill, and pick inventory is strongly influenced by where and how inventory is kept in a warehouse. Pre-packaging procedures must be completed for certain goods received at a warehouse before they can be stored away. These operations need to allocate a separate warehouse site. The software has a lot of features that make it easy to manage the inventory execution process. It also gives you full insight into the supply chain’s individual shipments. The system also allows for the redirection of incoming inventory to the proper location based on quality profiles or cross-dock needs.

THE IMPORTANCE OF VISIBILITY INTO INBOUND SHIPMENTS

Adding features like incoming visibility helps us move closer to our objective, but it also has its own set of benefits. Collaboration among supply chain partners is required to achieve these benefits, especially in terms of exchanging accurate, timely data. When suppliers and customers cooperate and exchange incoming shipment data, they can make better decisions and provide better customer service.

Both outgoing and incoming shipments must be visible in today’s supply chain. Visibility technology’s ultimate aim is to improve supply chain transparency.

SUMMARY

Both outgoing and incoming shipments must be visible in today’s supply chain. When suppliers and customers cooperate, they can make better decisions and provide better customer service. Visibility technology’s ultimate aim is to improve supply chain transparency; adding features like incoming visibility helps us move closer to this objective.

IMPROVING INBOUND VISIBILITY WITH MICROSOFT DYNAMICS 365

Global supply chain disruption has heightened the requirement for operational agility. Manufacturers, retailers, and distributors may use Dynamics 365 Supply Chain Management to react rapidly to changing consumer demand and maintain company continuity while being profitable.

A major source of supply chain risks is a lack of real-time visibility across several channels. Organizations require real-time cross-channel inventory information to guarantee that they are stocking their distribution centers worldwide with the appropriate mix and amount in order to create adaptive and flexible distribution and manufacturing processes.

Large-volume businesses and manufacturers may use Dynamics 365 Supply Chain Management to quickly manage a high number of transactions per minute and correctly estimate cross-channel inventory in real time. This allows businesses to quickly expand to meet orders from various channels on time while avoiding stock-outs and overstocking. If you have any questions for us, feel free to contact us at help@instructorbrandon.com.

SUMMARY

Manufacturers, retailers and distributors may use Dynamics 365 Supply Chain Management to react rapidly to changing consumer demand. Organizations require real-time cross-channel inventory information to guarantee that they are stocking their distribution centers. This allows businesses to meet orders from various channels on time while avoiding stock-outs and overstocking.

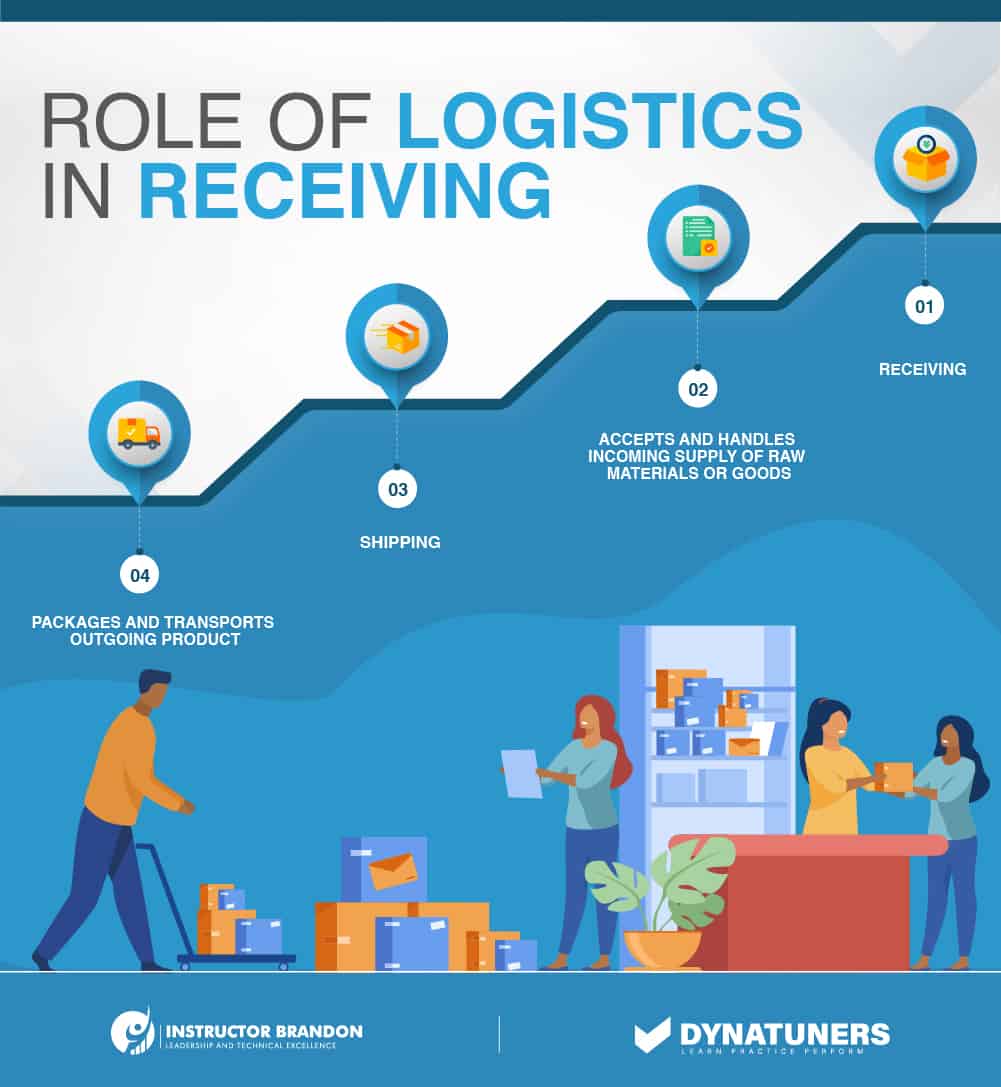

ARRIVAL OVERVIEW IN MICROSOFT DYNAMICS 365

This feature includes the Arrival overview page, which displays a list of all items that are scheduled to arrive as incoming items. The Arrival Overview page displays a list of all goods that are anticipated to arrive. It also displays arrivals that may be set up using the overview. The receiving procedure is the subject of this article. A user may obtain an overview of the current tasks and an approximate estimate of quantities, volume, weight, various order types on the Arrival summary page.

SUMMARY

A user may obtain an overview of the current tasks and an approximate estimate of quantities, volume, weight and order types on the Arrival summary page.

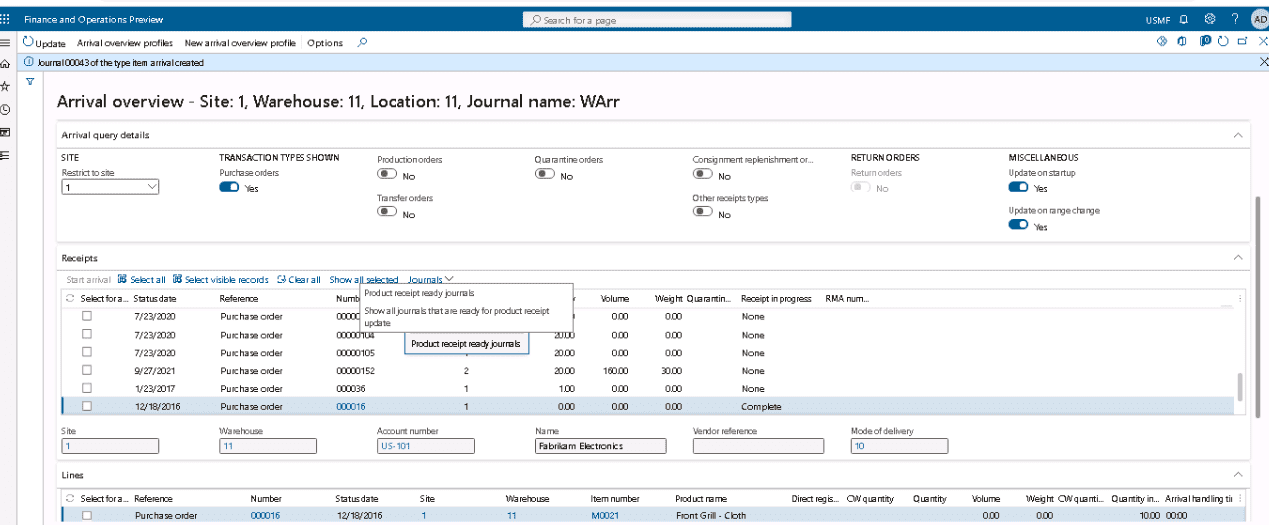

FUNCTIONAL WALKTHROUGH OF ARRIVAL OVERVIEW IN MICROSOFT DYNAMICS 365

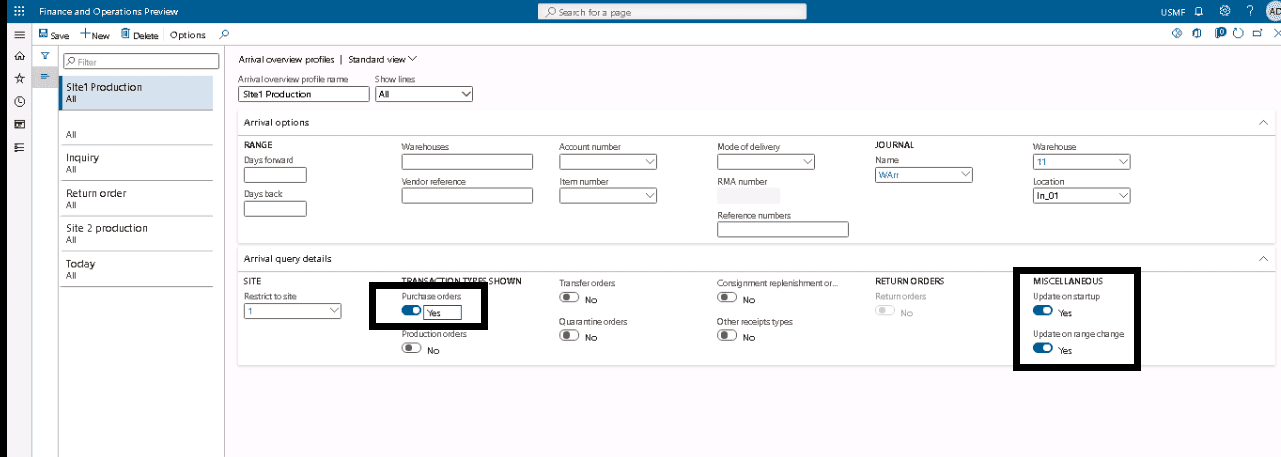

STEP 1:

Click Inventory management > Inbound orders > Arrival overview to see the Arrival overview page.

- Create a new setup called Site 1 production and provide the following parameters on the Arrival overview profiles page.

- Enter information about a day interval and the warehouses to include in the overview in the Range field group on the Arrival Options Fast Tab.

- Enter a receiving warehouse, a location, and a journal name (item arrival/production input) in the Journal field group of the Arrival Options Fast Tab.

- Now Enter a site in the Restrict to site field on the Arrival query details Fast Tab’s Site field group to restrict the view in the overview section.

- Set the Production orders option to Yes on the Arrival query information Fast Tab, in the Transaction types displayed field group.

- Set the Update on startup option to Yes in the Miscellaneous group on the Arrival query details Fast Tab if the view should be automatically updated at startup. If the display should be automatically updated when range values change, set the Update on range change option to Yes.

- For this example, the Arrival overview profile field on the Arrival Options Fast Tab of the Arrival overview page is set to Site 1 production.

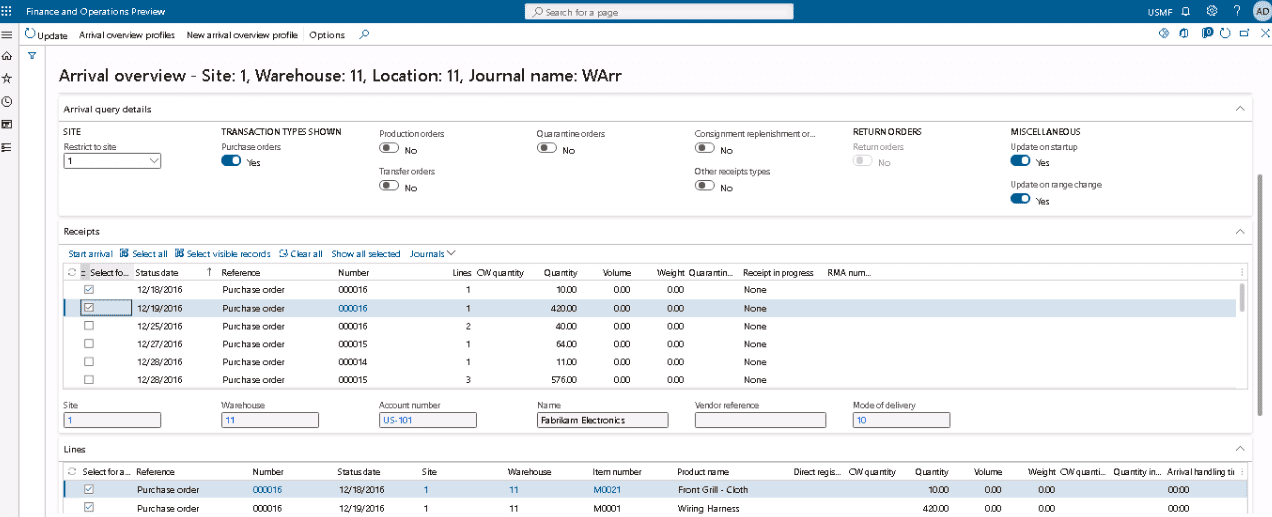

STEP 2:

On the Receipts Fast Tab, select a line and then clicks Start arrival. All related lines that are in the specified range and have a quantity to register are automatically selected. An item arrival journal is generated that has a match between the expected receipt order and the journal. The quantity is automatically initialized on all lines that are created.

UPDATE JOURNALS

STEP 3:

To register one or more order lines that are due to be processed, the user can select the lines in the overview grid or in the line grid, and then click Journals > Show arrivals from receipts. The item arrival headers that match the lines are shown. To update the purchase order product receipt for the registered items, the user can access the item arrival journal headers that are ready for update. To access these item arrival journal headers, he clicks Journals > Product receipt ready journals. All the header lines that are ready for product receipt update in the specified warehouse range are shown. (The header lines that are shown aren’t related to the day interval).

PROCESS A PRODUCT RECEIPT

Warehouse or buying managers may add the physical cost of acquired products once all things have been recorded and updated with a product receipt. Follow these procedures to make changes to your arrival information and to add a product receipt to your online store.

Once you’ve selected the journals to be updated, click on the Functions menu and choose Product receipt.

If the product receipt number isn’t in the journal, enter it on the Posting page and click OK to process the receipt.

DEMAND FORECASTING IN WAREHOUSING

Your warehouse serves as a barometer for your business, measuring the health of your sales as well as their variations. As a result, if you want to prevent product shortages and overstocking, effective inventory management, including managing the flow of products and sales forecasting, and your forecast model becomes critical. Monitoring inventory turnover and coverage rates may help you reduce the risks associated with demand variations and maintain a healthy balance between inventory turnover and supply. Logistics, more than any other step in the supply chain, has a poor reputation. This seems to be due to a mix of the unpredictability of unknowns such as weather patterns and fuel prices, as well as the recent rising expenses involved with last-mile delivery. This powerful combination makes it all the more surprising that logistics is often neglected when it comes to implementing demand forecasting lessons.

At its most basic level, demand forecasting is analyzing past consumer demand data, combining it with projections for future purchasing trends, and calculating how much product you’ll need at a particular time and location through several forecasting techniques. Load distribution, flexibility in the event of interruptions, seasonality, inventory costs, and inbound logistics planning are the five main areas where good demand forecasting may help you prepare for the apparently unexpected, reduce costs, stockouts and simplify your logistics planning efforts.

SUMMARY

Effective inventory control is critical to preventing product shortages and overstocking. Monitoring inventory turnover and coverage rates may help reduce the risks associated with demand variations. Good planning and demand forecasting may help you prepare for the apparently unexpected, reduce costs, and simplify your logistics planning efforts.

WAREHOUSE FORECASTING

Warehouse forecasting tells you how much inventory you’ll need at a particular place and at a specific time. Consequently, it’s a great way to estimate how much merchandise you’ll need to deliver to those particular places at those specific times. And, if you determine what your typical demand is, you can combine all of that data and use available pallet space during the off-season to pre-load important locations with the goods they’ll need when the surge happens.

SUMMARY

Warehouse planning and forecasting is a great way to estimate how much merchandise you’ll need to deliver. It enables logistics managers to allocate goods more efficiently across sites. Consequently, you can be certain that the right product is at the right place to meet customer demand.

WHEN IT COMES TO LOGISTICS, FLEXIBILITY IS EVERYTHING

Disruptions occur. There’s just no way to know everything ahead of time enough to avoid a cargo reroute or work around an unforeseen fuel shortage. As a consequence of improved planning and inventory management, you’ll have goods strategically placed to take up the slack and replace stock that’s depleted as a result of a natural catastrophe when a disruption occurs (or whatever event impacted the supply chain). Because you may move current goods as required without incurring any long-haul expenditures or losing any existing warehouse space, this type of flexibility can help keep the costs of these interruptions in control.

SUMMARY

With improved planning and inventory management, you’ll have goods strategically placed to take up the slack from depleted stock. You may move current goods as required without incurring any long-haul expenditures. This type of flexibility can help keep the costs of these interruptions in control.

THE IMPACT OF SEASONALITY ON LOGISTICS FORECASTING

Seasonal demand variations are another aspect of logistics and forecasting that is often neglected. Everyone appears to be shipping everything to everyone else during the holidays. Having your goods in place ahead of time can help you get through the season without suffering any financial losses. You may be confident that the artificial intelligence that produced the prediction took into consideration all available data in advising you when to send that product and the most strategic location to keep it if you plan ahead of time, based on predictive analytics employed in demand forecasting. To read more on demand forecasting, read our blogs.

SUMMARY

Having your goods in place ahead of time can help you get through the season. Predictive analytics are employed in demand forecasting. You may be confident that the artificial intelligence took into account all available data in advising you when to send that product and the most strategic location to keep it.

|

Sr. |

KPIs for Warehouse Forecasting | ||

| KPI | Description | Calculation | |

|

1. |

Availability rate calculation | The availability rate is the % of products available at a given time T. | I have 100 products in my catalog, only 80 are available for my customers, so I have the availability of 80/100 = 80% |

|

2. |

Service rate calculation | service rate is the ratio of orders delivered over time to the total number of orders. | Calculated by the orders delivered / order received |

|

3. |

Stock rotation calculation | Also called stock life or stock coverage, it is the average number of days that the stock takes to run out. | Average Stock / Total Sales x Number of Days within the selected period

This calculation must be done over the last 52 weeks to have a reliable KPI |

|

4. |

Stock coverage calculation | Use future sales forecasts to estimate your future inventory turnover. | average stock = current stock + stock in transit |

|

5. |

Forecast accuracy calculation | Retrieve your forecasts by item and your sales over the desired period. | 1 – (sum absolute difference per item / total sales) |

INVENTORY COSTS: A LOGISTICS BUDGET’S HIDDEN KILLER

On its way to its ultimate destination, how many warehouses does your merchandise pass through? We’ve previously discussed inventory shuffles and how adjusting what you ship where and when using demand forecasts may have a significant effect on your logistics costs. However, there is one aspect we haven’t discussed: the fact that these short stop-overs may frequently be significantly reduced or even eliminated. The halt is usually required to transfer pallets between trucks or to hold partial shipments while waiting for the rest of the order to arrive before the whole order is repacked for final delivery. If you know you’ll be receiving large orders from one place in the future months, you may utilize the time to progressively stock up on the appropriate products in a nearby warehouse so you’ll be ready to go when the order arrives.

SUMMARY

Stopover periods between warehouses can be significantly reduced or eliminated. The halt is usually required to transfer pallets between trucks or to hold partial shipments. If you know, you’ll be receiving large orders from one place in the future, stock up on products in nearby warehouses.

INBOUND LOGISTICS SHOULDN’T BE OVERLOOKED

Quality demand predictions produced by sophisticated analytics and AI-powered technologies may help both the incoming and outbound sides of your logistics business. Knowing about manufacturing runs ahead of time allows your planners to estimate how much of each raw material will be required and where it will be stored. They may better distribute material orders with this enhanced information, reducing the expenses of repeat purchases or emergency resupplies owing to inadequate resources on hand.

The bottom line in the logistics industry is ultimately client satisfaction through demand management. The capacity to predict how much of what will be required, as well as when and where it will be required, is critical to achieving that objective and that, in turn, is the logistical key to happy, loyal consumers. Visit our blogs to read more on warehouse outbound shipments.

SUMMARY

Knowing about manufacturing allows your planners to estimate how much of each raw material will be required. They may better distribute material orders with this enhanced information. This reduces the expenses of repeat purchases or emergency resupplies owing to inadequate resources on hand.

At Instructor Brandon | Dynatuners, we always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you’re interested to consult with our specialists on improving your supply chain’s visibility and expand operations without disruptions, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is warehousing forecasting? ” answer-0=”Warehouses can utilize forecasting to keep track of sales and anticipated demand, ensuring that the existing stock is sufficient to meet client demands. Customers can enjoy accurate and timely delivery of their items, and the firm does not need to order more than it will sell. ” image-0=”” headline-1=”h2″ question-1=”What is the concept of inbound supply chain management? ” answer-1=”Inbound Supply Chain Management is the process by which businesses obtain raw materials, parts, components, and a variety of products and services from a variety of vendors in order to carry out their operations. Procurement is another name for this process. ” image-1=”” headline-2=”h2″ question-2=”What is the meaning of an inbound warehouse? ” answer-2=”The inbound flow in a warehouse starts when things arrive in the company location’s warehouse, either from outside sources or from another company location. Warehouse actions are performed at various levels of complexity to transfer products into the storage area from the receiving dock. ” image-2=”” count=”3″ html=”true” css_class=””]

3653

3653