Dynamics 365 Tutorials, Microsoft Dynamics 365 Developer (F&S) Training Series, Supply Chain and Logistics Management

Techniques to Reduce Freight Charges with Shipment Consolidation Policies Using Dynamics 365 Warehouse Management

Reduce Freight Charges with Shipment Consolidation Policies

Shipment Consolidation | Sales Order Picking | Consolidation Polices

Recently, one of our customers has been suffering from severe organizational issues, causing them higher shipment costs. It wasn’t easy to identify the root cause behind those expensive shipments. However, in-depth research revealed that it was deeply associated with stocks, order preparations, and the absence of consolidated shipment policies.

Today’s post will shed light on shipment consolidation policies offered in Microsoft Dynamics 365 interface and how you can configure those policies. However, before getting to that part, let’s see how Dynamics 365 defines shipments.

Shipments in Dynamics 365

Remember that part where we create a sales order and release them to the warehouse using warehouse management; while we do so, the system establishes a shipment and a shipment line. However, here, a shipment is said to be delivered to a single sales order having a similar mode of delivery. Further, the shipment lines and ways of delivery of various sales orders against the same delivery address can be on the same load line.

You can configure shipment consolidation policies by going to Warehouse management > Setup > Release to warehouse > Shipment consolidation policies.

You can release sales orders to the warehouse in different ways; Although, for the sake of today’s post, we will be focusing only on the instances relating to shipment consolidation.

Just for the ease of use, you can use shipment consolidation policies (SCP) from the following place in D365:

- Shipment workbench for taking control manually over consolidations

- From the Load planning workbench, you can use the Release to warehouse function

- You can also toggle consolidations through Release to warehouse function from within sales or transfer orders

- Or Automating consolidation through Release to warehouse batch job

Before this functionality, the shipments consolidation at Release to the warehouse was a general setting that the user had to apply to different warehouses. This new SCP encourages flexibility for customers having varying and more complex requirements for consolidating shipment policies.

Shipment consolidation policies leading to better warehousing

Imagine a customer placing an order at your firm shipping orders in parcels considering a general scenario. Once you have received an order, it will be released to the warehouse. However, after a few minutes, the same customer places another order, which gets released to the warehouse.

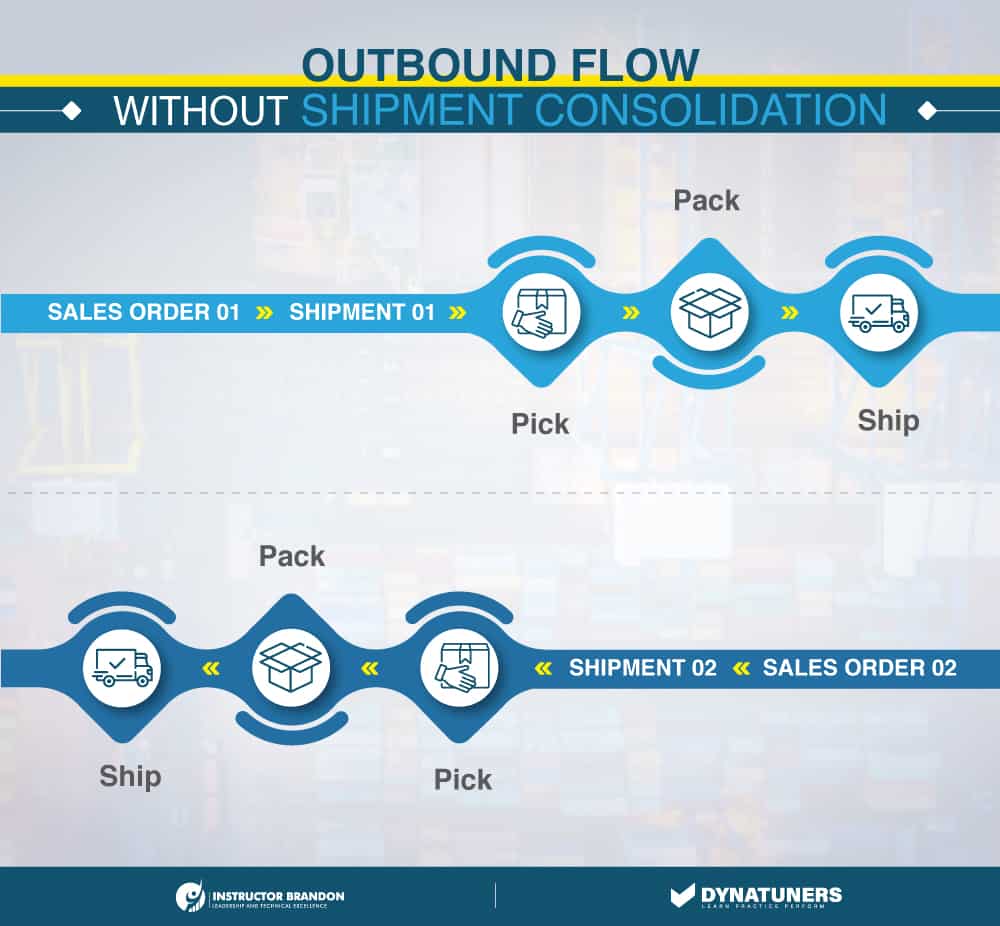

In this case, D365FO will generate two outbound shipments, two pick works, resulting in two pick tasks, two-pack tasks, and shipment of two different parcels to the same customer without consolidating on its own.

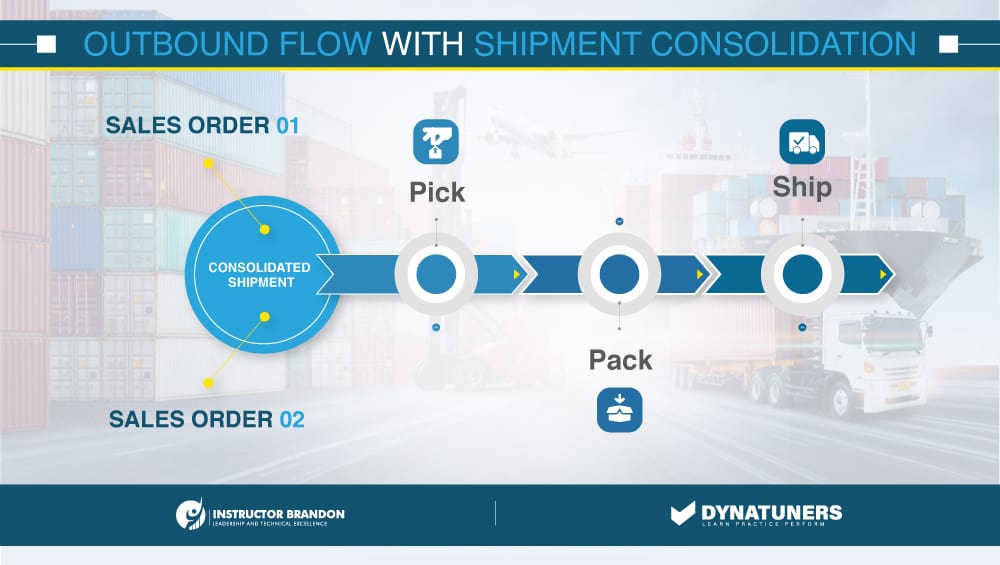

Here is an illustration of an unconsolidated and consolidated outbound shipment flow.

Implying the first example, let’s talk about different scenarios in which consolidation can be helpful for your company.

- Suppose one of your customers has a peculiar way of placing its order. When you come across multiple sales orders from one customer, one might think, why would a customer send sales orders for multiple lines having the same quantity, identical item, and delivery address? Instead of sending one sales order line having a total amount required of an item to be delivered? Trust me, and this happens often. Consolidating your shipment would be ideal for such circumstances.

- In another example, you stumble on a customer placing a sales order irregularly while having the same mode of delivery, i.e., by a truck. Again, SCP is perfect for taking care of such sales orders.

- With SCP, you can create and apply a consolidation policy against items getting attentive shipping and handling concerns in D365FO.

Fields to work with while consolidating shipment policies

Let’s say you have an open consolidated shipment option for each policy. When we turn on this option, the Release to warehouse tracks the shipments available for consolidation through searching existing on similar consolidation policy.

When we work with a shipment consolidation policy, each one has a query or field to use. Some of these fields are compulsory, while others add more detail to the shipment. Here are some of the useful fields that we can include as a part of the shipment consolidation policy:

- Order number

- ISO country code

- Address

- Site

- Shipment carrier

- Carrier service

- Mode of delivery

- Carrier group

- Broker ID

- Shipment ID

- Delivery terms

- Customer reference

- Wave ID

- Customer requisition

SUMMARY

Every one of us wants to have cheaper shipments, faster outbounds, and more money. Dynamics 365 is a great tool to brace your goals if you are into the business with such goals.

At Instructor Brandon, we tune your workspace and deploy methods like shipment consolidations to help you save both time and cost.

Consolidation with Enriched Sales Order Picking

We all know that order picking is a prime aspect of efficient warehousing. Still, at our client’s warehouse, everyone was panicking to find the perfect order for their products. To be honest, it was chaotic. Since we wanted to minimize their costs and provide superior customer service, something needed to be done. Taking that into account, we helped them set several practices to meet their higher accuracy demands speed up the shipments.

We help our clients to get an understanding of order picking enhancements to fulfill sales orders. Moreover, we also assist in setting shipment consolidation policies in Dynamics 365 Supply Chain Management.

Before setting up our shipment consolidation policies, let’s discuss what exactly consolidation is. It is when we group several items to save cost and send them in one go.

What does Sales Order Picking Have to do With Shipment Consolidation?

Perfecting sales order picking has a lot to do with consolidating shipments. Without a doubt, order picking is among the most exhausting task in warehousing. However, several things play their role in factorizing order picking.

Let’s start with the infamous Mis-picks. So, Mis-picks can drastically affect the efficiency of your while negatively impacting customer satisfaction and exhausting your employees, whether they are your supervisors or order pickers.

Back in 2012, a study calculated an average loss of each Mis-picks as $22; it may not seem much but, over the course of one year, this can add up to a lot. Below is a brief overview of average Mis-picks happening in the US industry.

| Cost for 1% Mis-pick Rate Per Annum | ||

| Demo Value 1 | Demo Values 2 | |

| Lines Per Hour | 65 | 250 |

| Average SKU/Orders | x3 | x3 |

| SKUs Picked Per Hour | 195 | 750 |

| One 8 Hour Shift | x8 | x8 |

| SKUs Picked Per Day | 1,560 | 6,000 |

| Mis-pick Rate | x1% | x1% |

| Mis-pick Per Day | 15.6 | 60 |

| Average Cost of Mis-pick | x$100 | x$100 |

| Total Lost Revenue Per Day | $1,560 | $6,000 |

| Working Days Per Year | x260 | x260 |

| Total Lost Revenue Per Year | $405,600 | $1,560,000 |

Staging Sales Order Picking to Ease Consolidation

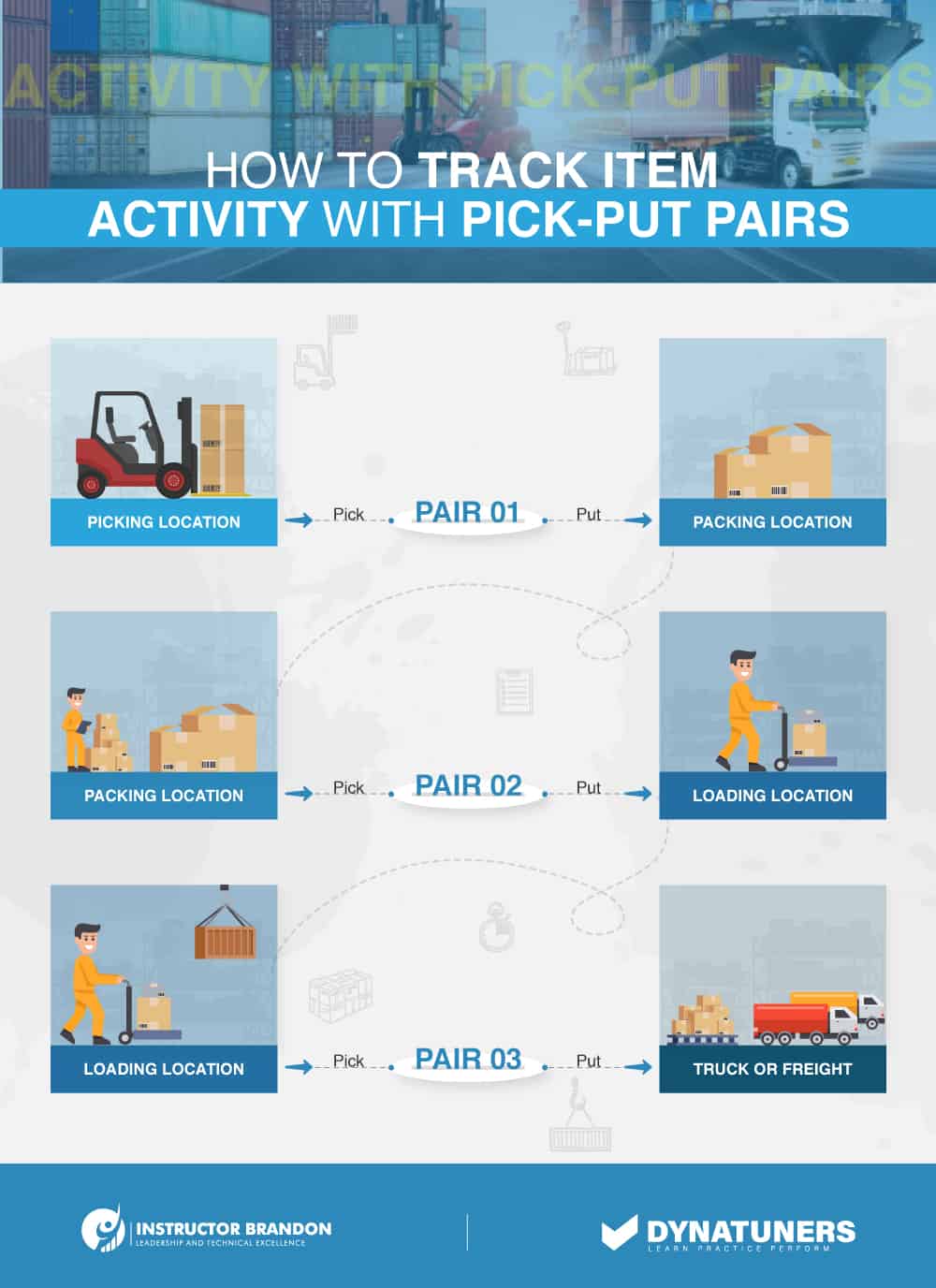

D365FO allows us to configure work templates and skip the staging steps. However, we would have to work with only one pick put pair.

So, we go for multiple staging methods if you are running more complex warehouse management. Such as, you can use several staging operations after your items are picked from the warehouse and demand a composite packing operation, which could be covering your items with bubble wrap to enhance the protection factor.

Once your items are done with the bubble wrappings, they are sent for docking and loading. In such a scenario, we can create three put pairs and track the activity of each item through the following pick-put pairs.

- The first pair will pick the item as it moves out of the pick location and into the packing point.

- The second pair will pick the item out of the packing point and put it into the loading location.

- And finally, the third pair will pick the item from the loading location and put it onto a freight or just move out of the warehouse.

However, you would need to configure a working template in Dynamics 365 and create locations directives to indicate correctly defined pick and put pairs. You can then link locations directives to the configured work template and indicate the system from where it should place the items. When we configure items for sales order picking, there are some additional options as well, which further help us manage the staging processes.

One option in Anchoring allows us to override loading or staging locations. When we use Anchoring, all subsequent open puts direct to new loading or staging location.

When the Anchoring option is set to yes, we can select to anchor by a shipment load. If you choose to set Anchoring by shipment, all subsequent open puts for the shipment will be changed to a new location for that shipment. However, if the Anchoring is set by load, all the following available puts will be relocated to the new location for a specific load.

SUMMARY

Order picking and shipment consolidation go a long way back. You see the way your shipments are picked has a lot to do with consolidating them onto fewer loads. As explained above, the three pick and put method can be one of the solutions to efficiently track your shipment at any given point.

Steps on Consolidating Shipment Policies

Step 01

Use feature management to turn on the Shipment consolidation policies feature if you haven’t already turned it on.

Step 02

In the Feature management workspace, the feature is named Consolidate shipment.

Step 03

Click Enable now.

Step 04

Go to Warehouse management > Setup > Release to warehouse > Shipment consolidation policies.

Step 05

On the Action Pane, select Create default setup to create the following policies:

- A Default policy for the Sales orders policy type

- A Default policy for the Transfer issue policy type

Step 06

The option to further define the consolidated shipment by policy type of sales orders or transfer orders, customer, and location, can be found at Warehouse management > Setup > Release to warehouse > Shipment consolidation templates.

Step 07

When sales and transfer orders are released to the warehouse, they are released and become available to consolidate. In Warehouse management > Shipments > All shipments there is an option to consolidate shipments, by selecting consolidate shipments.

Step 08

Shipments can also be manually managed in Warehouse Management > Release to warehouse > Shipment consolidation workbench. Select the template that was previously set up and select Consolidate shipments.

SUMMARY

By following the above steps, you can the consolidate your shipment by policy type of the sales orders, transfer orders, customer ID, or location. However, you can also set a default policy for sales order type and transfer issue policy type.

To gain further insights into creating consolidation policies, get in touch with one of our technical experts and have a briefing on setting and editing policies.

Concluding Consolidation

We, at Instructor Brandon | Dynatuners, know how important it is to carry out correct consolidation policies for the shipment of your items.

As it is an integral part of operations, you must keep things on the correct pick-pack order for the efficient supply chain management. Of course, Microsoft Dynamics 365 regularly innovates its applications to implement smooth warehousing. Dynamics 365 is a powerful tool helping improve your business processes.

In this post, we talked about:

- Shipments in Dynamics 365

- How consolidation policies can lead to better warehouse planning

- Fields to work with while consolidation shipment policies

- Integrating consolidations with sale and purchase orders

- Staging sales order picking for better consolidation

- Steps on consolidating shipment policies

In the end, we all want cheaper freight rates and higher profits; at least, that is the optimal path for any business.

So, if you are interested in consolidating your shipment policies, you can directly take assistance from our technical experts on anything related to warehousing, order picking, or consolidating shipment policies.

We always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you want to consult with our technical solutions experts on how we may help you reduce your freight charges by setting shipment consolidation policies in Dynamics 365, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is Consolidation in Logistics? ” answer-0=”Multiple LTL shipments from different carriers are combined into one full container multi-stop truckload cargo in a consolidated shipment. As a result, shippers can receive preferred rates by consolidating their loads, which helps to improve supply chain logistics by saving time and money. ” image-0=”” headline-1=”h2″ question-1=”What are consolidation adjustments? ” answer-1=”Adjustments must be made as part of the consolidation of a set of organizations’ finances. For example, suppose one group undertaking makes a profit on selling a fixed asset to another. In that case, the gain should be deducted from the profit and loss account in the consolidated balance sheet. ” image-1=”” headline-2=”h2″ question-2=”What are the two exceptions that allow for the clearance of a consolidated shipment at a primary warehouse? ” answer-2=”There are a couple of irregularities to the rule enabling aggregated shipments to be cleared at primary warehouses. The first one is Back-to-Backs. When a single non-consolidated house bill is cited on a House Bill Close Message (HBCM). And the second one is Consolidations of Buyers, where multiple home invoices are sent to a single importer in this situation. ” image-2=”” count=”3″ html=”true” css_class=””]

2675

2675