Supply Chain and Logistics Management

7 Ways to Improve Inventory Warehouse Management with D365

In this day and age, it has become important to have real-time insights into your supply chain, like resources, demand, and inventory and warehouse management processes like procurement, production, and distribution.

Microsoft Dynamics 365 Supply Chain Management gives you those insights by providing unified operations across areas like warehousing, planning, and transportation. Additionally, It has built intelligence on that integrated foundation, to provide key information to users that can identify issues and keep fulfilling orders. The rising intricate global supply chain operations, decreasing margins, demanding customers and increasing competition have created a clear business goal for all: delivering innovative and valuable services or products while reducing supply chain costs. The traditional enterprise resource planning (ERP) systems were not designed for today’s digital world. Consequently, companies and specialists need a tailor-made supply chain solution; one that not only responds to the market’s demands but instead manages it, delivering operational excellence.

In this post, you are going to see what it takes to set up these responsive operations using Microsoft Dynamics 365 Supply Chain Management.

Points to consider in Inventory and Warehouse Management with Dynamics 365

In this post, we will discuss:

- What is the Inventory Management System?

- Why Inventory Management is Important?

- What is Warehouse Management?

- Why Warehouse Management is it Important?

- What is the Difference Between Inventory Management and Warehouse Management?

- 7 Ways to Improve Inventory and Warehouse Management with Dynamics 365 SCM

- Takeaways: Dynamics 365 Inventory Warehouse Management

What is Inventory Management System?

The Inventory management system is about counting all the items in the warehouse, tracking all movements, and asking for more when they lessen. In other words, it is the process a business should follow to organize products in the warehouse efficiently. However, like all such things in life, inventory is a complex task and demands detailed processes rather than a simple one-and-done kind of process. Therefore, It could possibly be the most important aspect of any type of business because it affects every area of operations:

From sales to accounting and management to customer service.

Managing inventory includes a series of tasks that need to function in synchronization on a daily basis to achieve the desired results. Let’s start with the basics and get into more technicalities as we go.

Types of Inventory

You can divide them into three major categories:

- Raw Materials or Parts

- Finished Products

- Assets (items that are used in day-to-day operations)

What are the Methods of Inventory Management?

To evaluate costs:

- Carrying Costs

- Landed Costs

To evaluate inventory:

- First In, First Out (FIFO)

- Last In, First Out (LIFO)

- Average Cost

- Standard Cost

- Actual Cost

To manage inventory:

- Manually

- Microsoft Excel

- Inventory Management Software

To classify inventory:

- Min-Max System

- Two-Bin System

- ABC Analysis

- Order-Cycling System

What is Warehouse Management?

Warehouse management is the spine of any type of company that produces, stores, or delivers a product. In other words, it is the physical place where a huge amount of investment is located. Even the companies which don’t manufacture goods have some kind of storeroom for different items that they use on a daily basis. The building itself is one of the company’s investments, providing the physical space for handling products, storage, and the workforce that is operating all of these. Thus, the employees of the said firm are managing the incoming and outgoing goods in this ‘storage space’.

How do you ‘Manage’ Warehouse Management?

A warehouse is within a warehouse management system; so it is also part of the supply chain. Warehouse Management is the systematic process of optimizing and controlling the operations and storage of all the products in a warehouse; from the moment the goods arrive at the facility until they are shipped out to customers.

What is the Process of Warehousing?

Warehousing is the procedure of storing goods in a way that is traceable, and in a secure condition before they’re sent out of the warehouse for whatever reason. In fact, this process is present in every business no matter the size; for example, small retailers have small storerooms as warehouses, versus large businesses that even buy or rent big buildings designed for these purposes.

Why is Inventory and Warehouse Management Important?

Imagine a simplified version of the inventory and warehouse management of any company: you are going to get the goods delivered that come into receiving. Next, all these items (in receiving) eventually must be put away on the shelves at the warehouse. Later, you are going to move these items. Some of them might be moved to be used in a manufacturing process, or maybe the business might be involved in wholesale distribution and is sending them out to customers.

Regardless of whether you’re manufacturing the finished goods or sending out parts, all those pieces need to be ‘shipped out’ at some point. A lot of companies will manually process all this to keep track and accomplish their business processes. However, this is excessively labor-intensive work, and there is a lot of data that the company needs to keep track of. For example, a small sampling of data that your company must handle during all this is lot numbers, serial numbers, cost quantities, shipment, and dates for production/expiration.

It is imperative to remember during all this that when goods come into receiving, data needs to be captured for efficiency purposes and to keep track of your inventory. When it is moved from receiving over to the shelves, or when the goods are pulled out, the company needs to update all of this information and track it regardless. So, if it’s a manual process, the business is involved in a lot of labor-intensive activity to move these items all the way through to pick, pack and then ship them.

Is an Automating Inventory Worth It?

The manual process can get a little messy, we won’t lie. In an automated process, however; when your company receives goods, you have a couple of options.

One is, for example, if it’s a large amount of cargo. An automated system would move it right into receiving and then scan it with a barcode scanner. Moving it to other locations, again, would require scanning, and your automated system knows exactly where the inventory is now. If it’s a smaller shipment that arrives, the company can skip this whole receiving stage and just barcode it right into the places where the rest of the storage is, or on the shelves.

This whole picking, packing, and shipping process that ends up in the final shipment is tracked through this automated system. When it ships out the door, the inventory is dynamically updated with real-time data, which ultimately gives us better information. That’s why companies are maximizing their operational efficiency and ensuring product quality at the same time. This way, the entire operation can shift from reactive to proactive.

Businesses, in their final accounting terms, want to increase tracking efficiency.

Your organization wants to do a better job of tracking all the processes effectively. Consequently, this decreases the amount of time spent doing this. Hence, the better the business information, the better the business. Any business’s decisions, having this automated system, become very valuable because of the reports that it can get. With better business information comes better reporting, greater efficiency, and fewer costs overall.

7 Ways to Improve Inventory and Warehouse Management with Dynamics 365 SCM

Maybe your current supply chain management is made by different applications, or it may be built internally. If the systems and their data schemes are different, the amount of time spent keeping them all in sync and avoiding duplicating data entry is a hassle.

Dynamics 365 Supply Chain Management (SCM) can:

- Provide a powerful solution with one application integrated into all the Dynamics 365 modules and apps. This allows you to streamline planning, production, stock, warehouse, and transportation for any type of business

- Boost your business with intelligent insights and the right instruments to respond. Predictive insights adopting Artificial Intelligence (AI) and Internet of Things (IoT) capabilities make this the most powerful solution.

- Help fulfill the orders by giving you deep visibility into product inventory. You can see inbound and outbound inventory operations and what’s in your warehouses.

- Secure the procurement process by identifying the fastest route or the least expensive shipment rate and provides tools to stay informed and respond to orders, ensuring coordination and agility.

- Optimize planning for your manufacturing fulfillment operations by using Azure Analytics to forecast demand and plan capacity, using real-time flexible resource management.

- Use the Microsoft Power Platform, so you can quickly build scalable web and mobile client apps and even integrate chatbots that share a common interface and unify data.

- Integrate with Power BI and provide reporting, powerful analytics across supply chain management and connected applications to give you a full view of your operations.

Step by Step with Dynamics 365 Warehouse Management

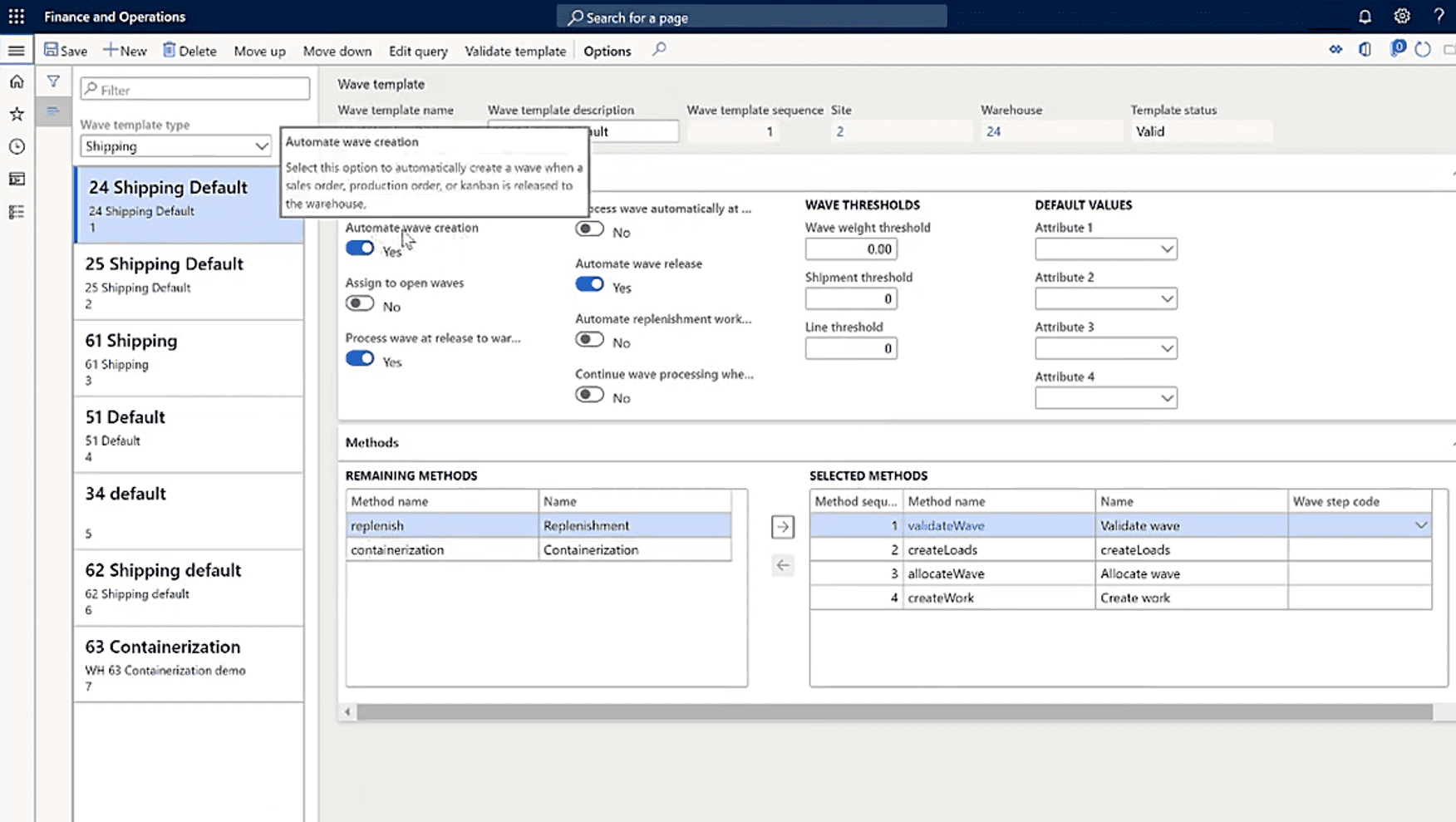

In the entirety of this series, as well as in our courses on this topic, we will delve into all the processes in-depth and in detail. However, we can give a small example of what this tool looks like. For instance, let’s see the Wave Templates automate creation, processing, and release inside the Dynamics 365 Supply Chain Management Warehouse Management Configuration. In particular, this works well for every situation, except if you have some specific business requirements to manually manage your wave process.

Therefore that’s why, without a doubt, we would recommend that you automate the wave creation process and release.

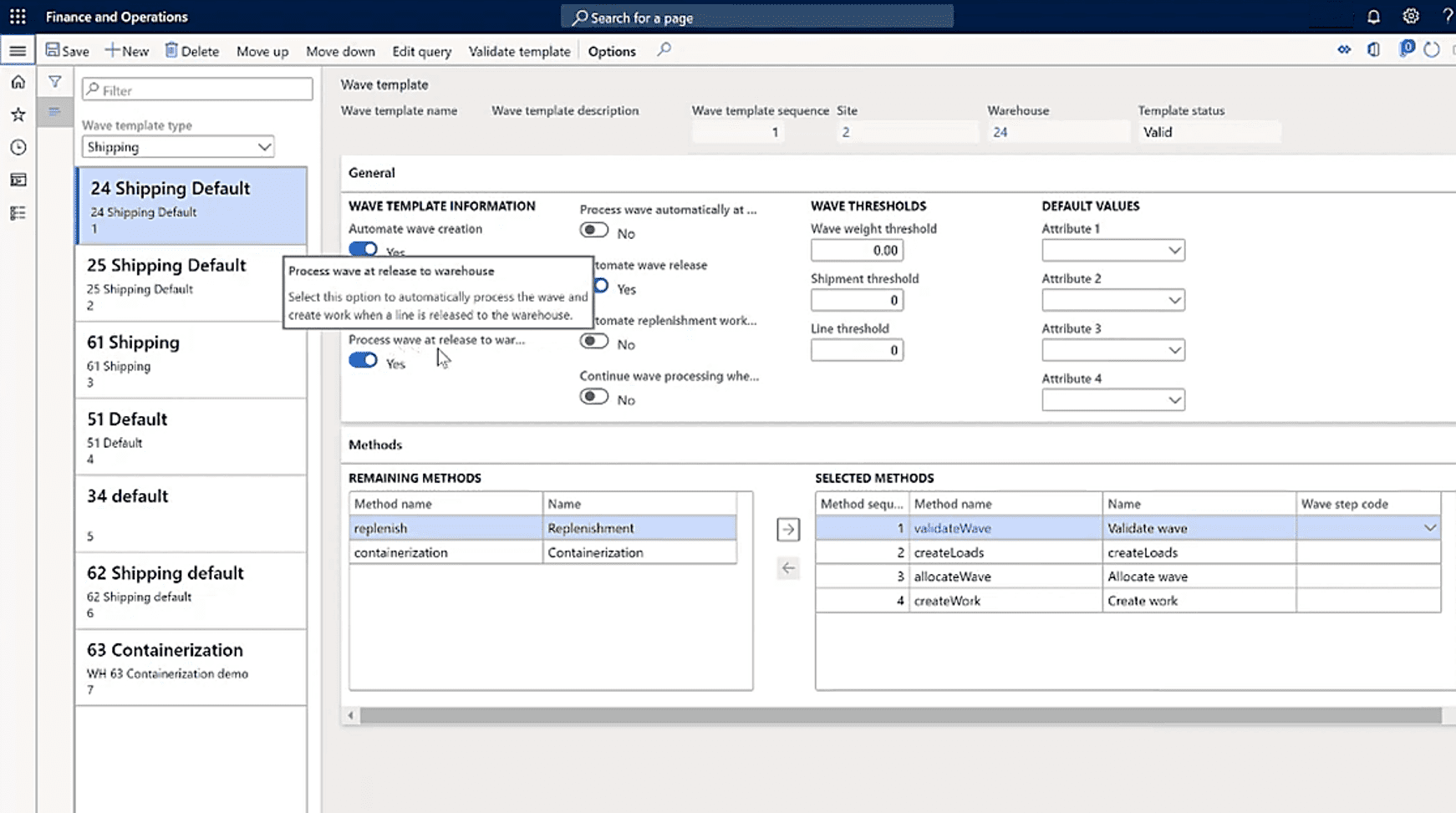

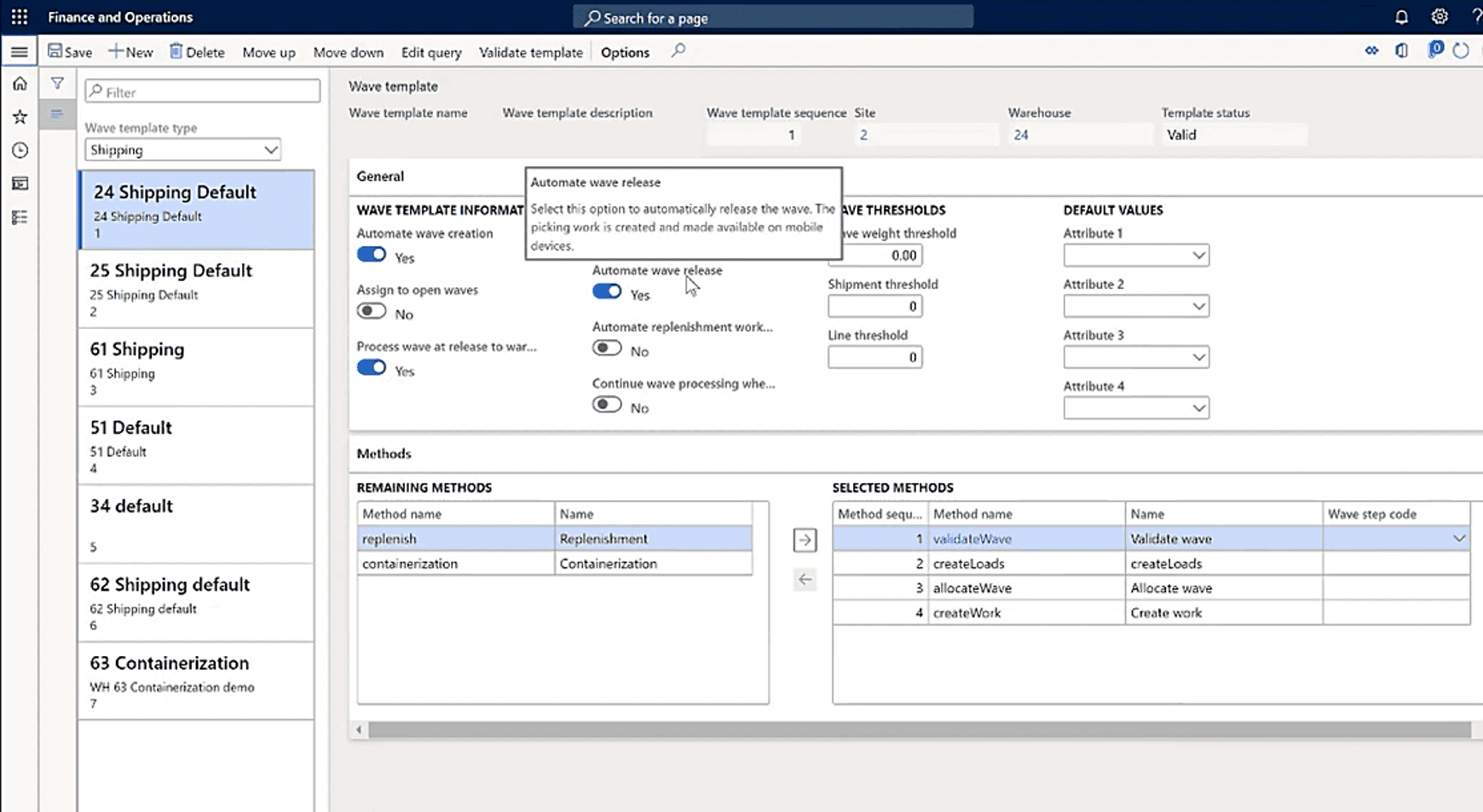

First, activate the automated creation process. Secondly, activate the automating processing of the wave, which is very beneficial, so when you release an order to the warehouse, that triggers this wave to begin. Thirdly, activate the automation of the release, this led to releasing the work that was created by the wave so that it is not blocked for processing. If you automate this, whatever work is generated can be immediately executed by your users, saving time, work and money.

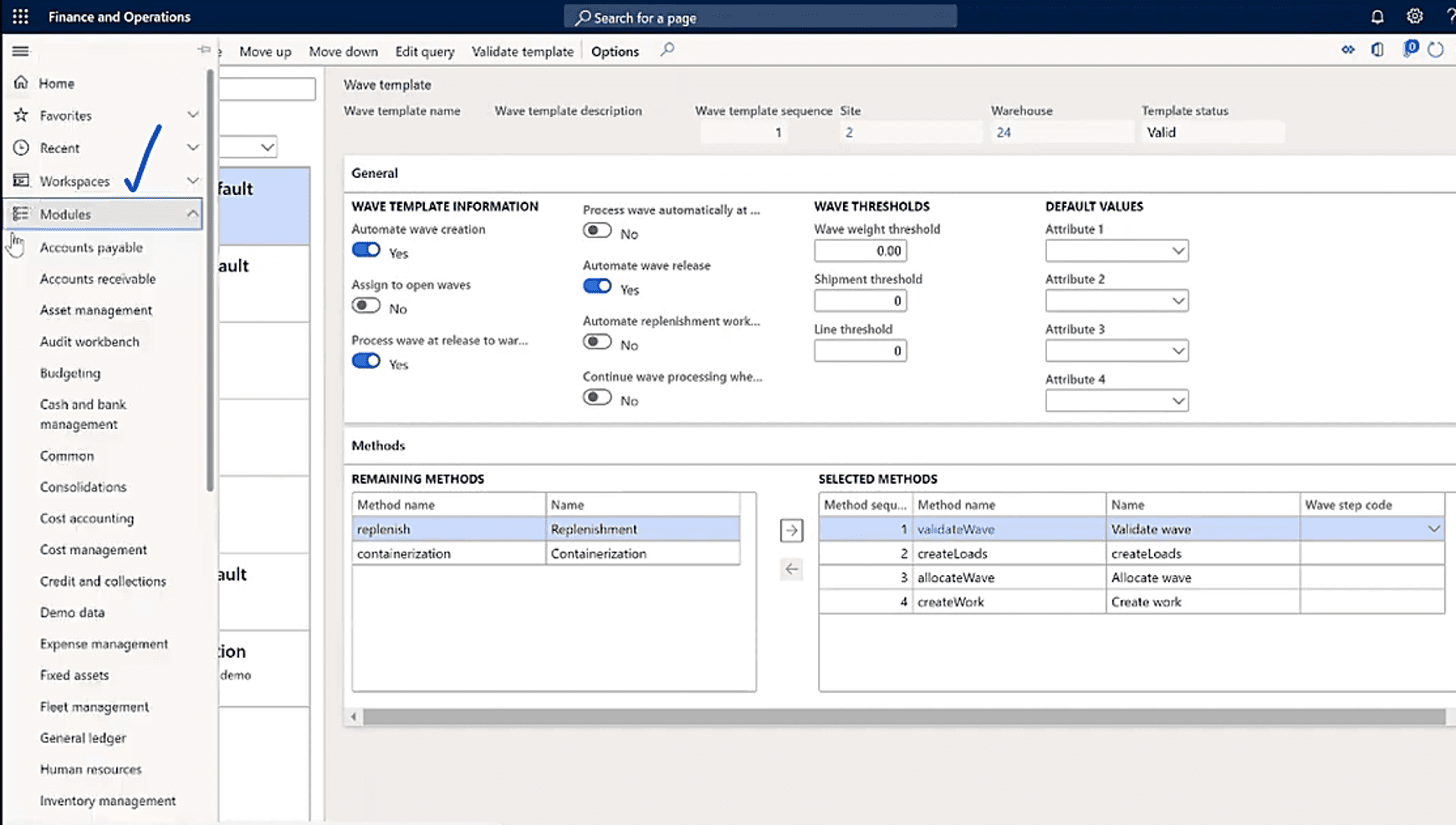

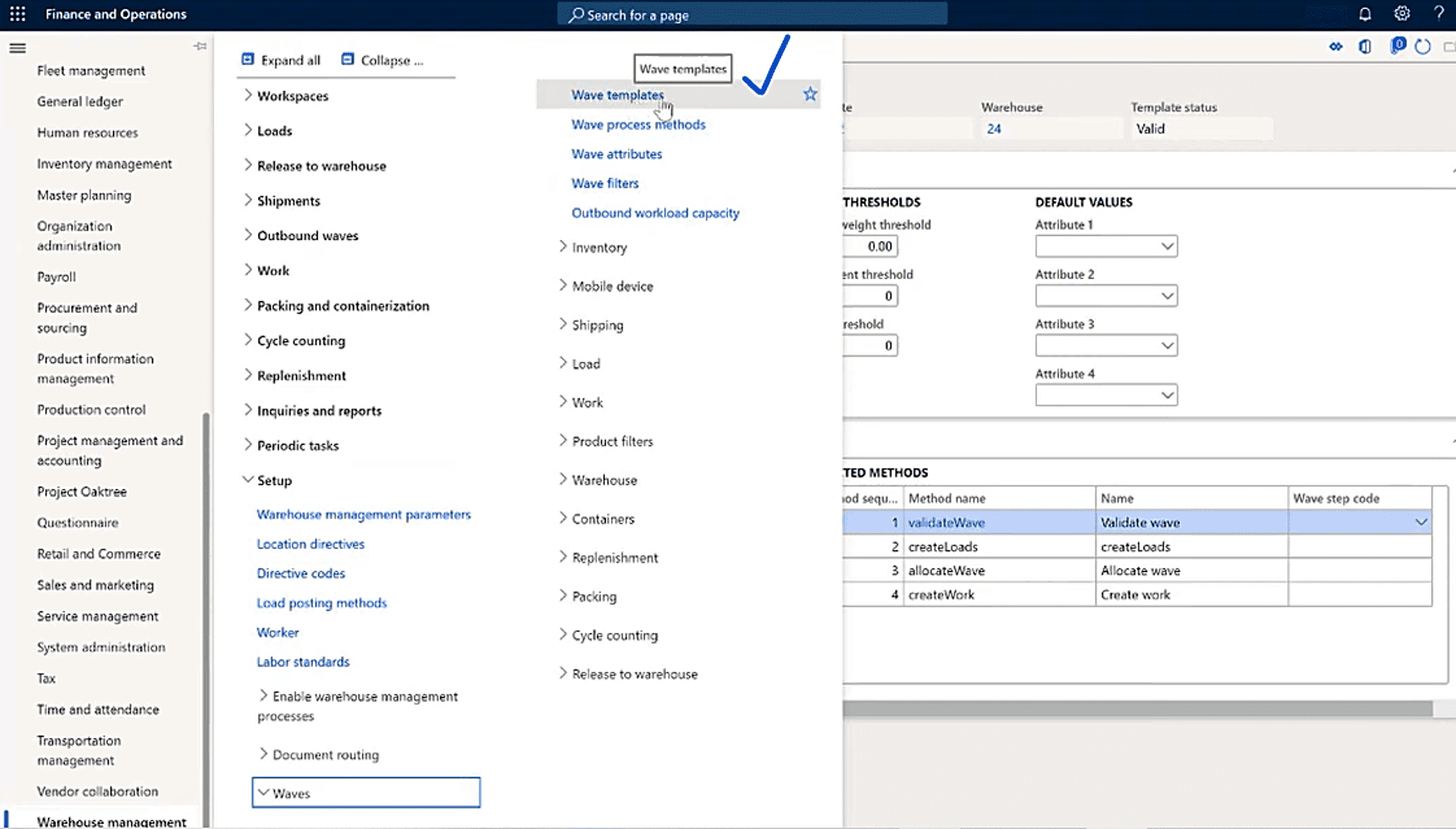

| Step 1

Go to the Navigation Pane and then select the option Modules |

|

|

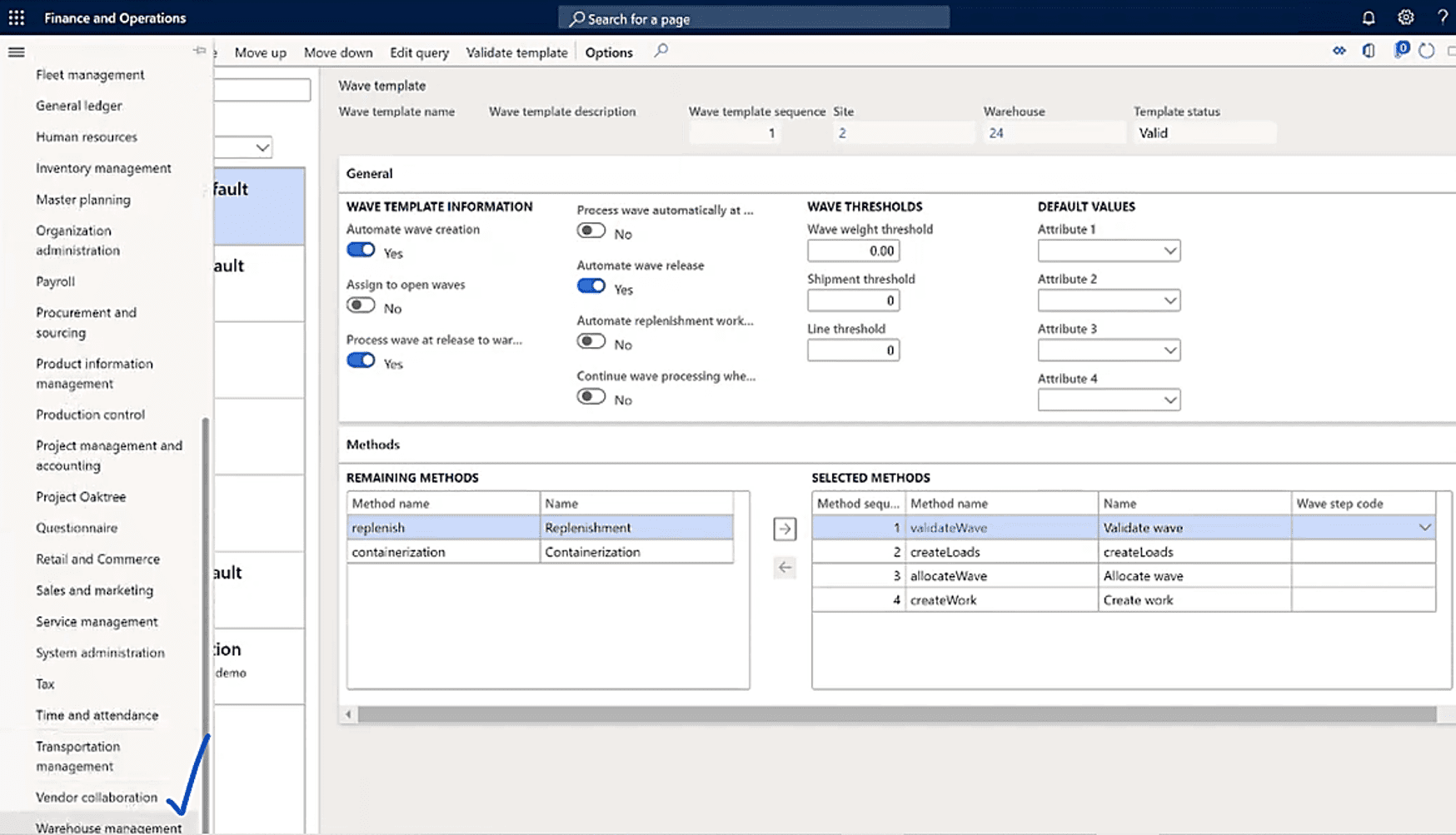

Step 2

Then go to Warehouse Management |

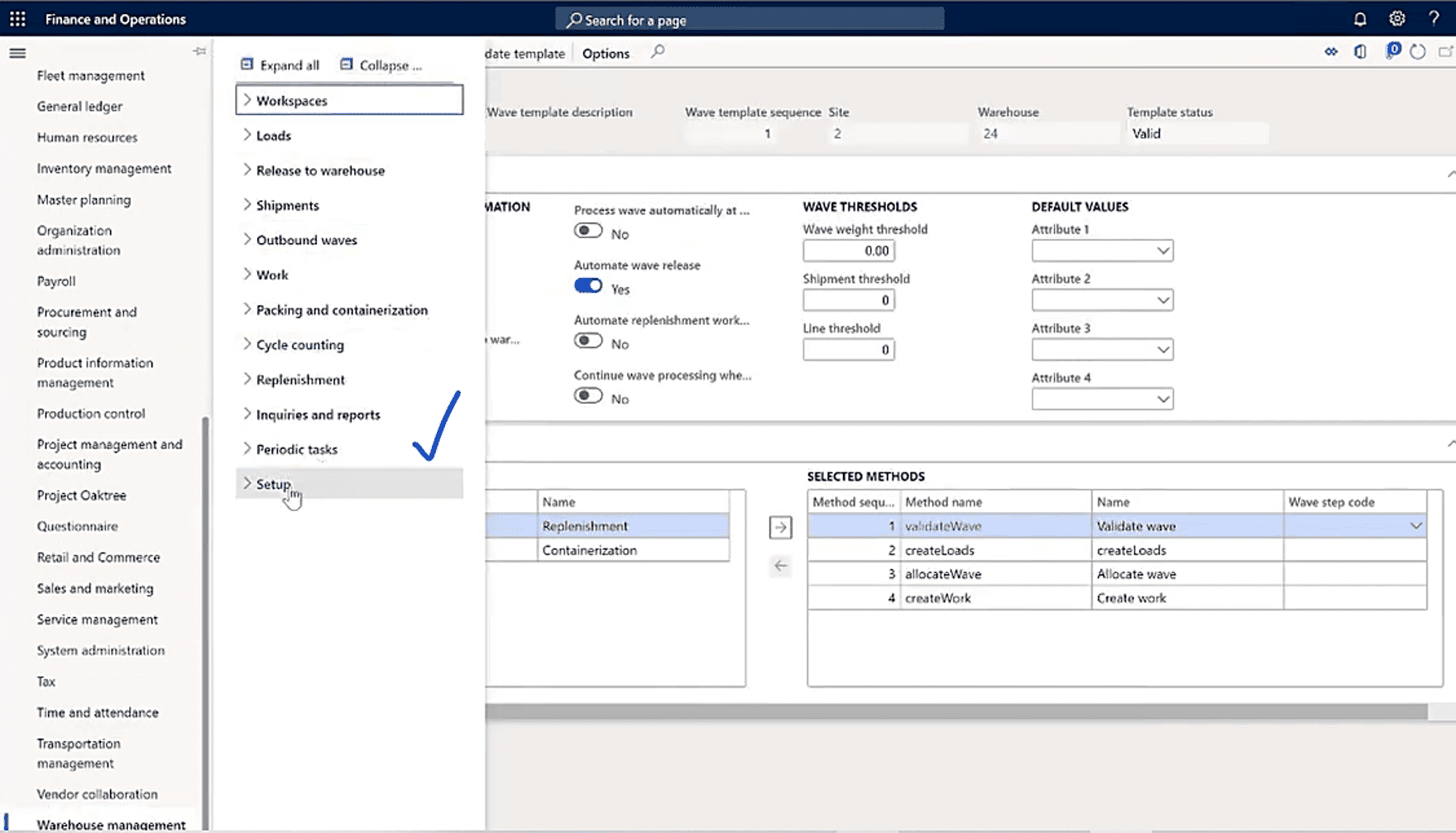

| Step 3

Select the option Setup |

|

|

Step 4

Below in the list, find the tab for Waves |

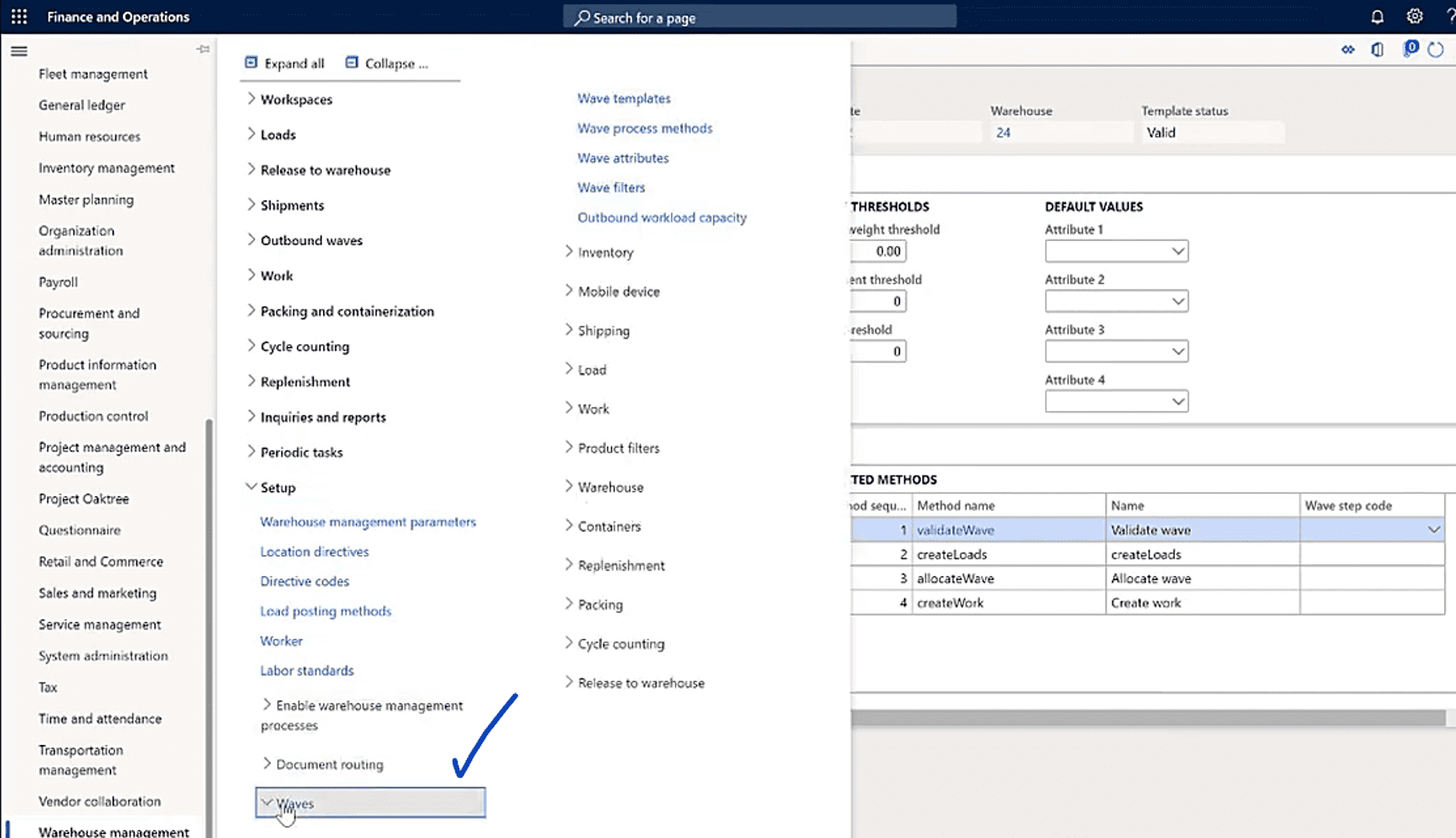

| Step 5

And click on Waves Templates |

|

|

Step 6

Go to the option of Automate Wave Creatin, and configure it on the yes. |

| Step 7

Next, repeat the process with the option Process Wave at Release to Warehouse |

|

|

Step 8

And again with the option Automate Wave Release. There you go! |

Seeing the Future of Inventory and Warehouse Management

For instance, internationalization is a high-risk strategy. In fact, any business can undertake this due to the complexity and uncertainty of environments. Nevertheless, not embracing this strategy means a major disadvantage to companies, in relation to their competitors with an international orientation. Furthermore, internationalized companies have shown a better capacity to innovate and adapt to the fluctuations of demand.

In addition, the business scenario has switched from companies competing as independent entities to a supply chain competing scenario. To illustrate, small businesses and medium-sized enterprises (SMEs) cope with many limitations due to poor capabilities, for example, innovativeness and lack of resources/production capacity. Then, they are recognized for being flexible. This can lead to a faster response and to have closer relationships with customers and suppliers.

Takeaways: Dynamics 365 Inventory Warehouse Management

Of course, in a dynamic business environment, to develop a competitive advantage, companies must synchronize their strategies, resources, capabilities, and operations. Therefore, suppliers adopting supply chain management (SCM) and supply chain flexibility (SCF) strategies, will have an edge over their competitors.

Moreover, companies must synchronize their own logistics capabilities within their network partners to compete with firms outside their supply chain. Then, supply chain agility is prompt by joining logistics capabilities together at a network level. Hence, logistics capabilities constitute a key element for developing supply chain broad capabilities. Also, you can check our MB-300 and MB-500 course to learn more about how to train your team. We are sure you’ll find it useful

Thank you for reading part 8 of our Supply Chain Series. If you have any questions, leave us a comment in the section below and we will get back to you. Additionally, make sure to stay tuned for our next blog post where we will talk more about this and other related topics.

Furthermore, if you want to learn how to leverage your business data using Supply Chain Management, you can reach out to us here. This has been Brandon Ahmad, founder of Instructor Brandon and Dynatuners.

What is an inventory management system?

It refers to the process of a system that assists companies to coordinate all the moving goods in a warehouse, indicates the stock levels the warehouse should have for every item, and generally maintains the supply chain efficiency. It has more to it, so keep going through this blog post to find more.

What are the types of inventory?

•Raw Materials or Parts •Finished Products •Assets (items in day-to-day operations) All of these have more values you need to learn, and we are giving a more detailed guide in this blog post.

What are the methods of inventory management?

•Evaluate costs •Assess the inventory •Manage inventory •Classify inventory Every method has detailed information about its composition and reaches, so continue reading this blog post for more guidance.

What is warehouse management?

It refers to the process of a system that assists companies in supporting the warehouse facility while integrating with many processes like purchase, quality control, manufacturing, transportation, transfer, sales, and returns. More of this topic in this blog, read along for a better understanding.

How do you manage warehouse management?

To handle warehouse management, you must have integrated support of source documents for sales orders, returns, transfer orders, production orders, and Kanban. So, a flexible, inbound, and outbound material workflow based on queries is also needed. Furthermore, it must integrate with manufacturing and transportation with full control of location stocking, limits, and location volumetric. This is just an overview of some points, you will find more information in this blog.

3908

3908