Supply Chain and Logistics Management

Different Types of Order Picking Methods in Warehouse

The different types of warehouse order picking methods in warehouses create different opportunities to fulfill your standards. When it comes to company procedures and processes, these can change the value of your supply chain management approach. From reducing time to securing customer satisfaction, picking methods are a key element to warehouse processes.

In this article, we are going to give a quick overview of:

- What is warehouse order picking?

- What are the different types of order picking methods in the warehouse?

- Why warehouse order picking methods are so important?

- Pros and Cons of warehouse order picking systems

Without any delay, let’s discover the different aspects that are linked to our topic, and how they would benefit your business.

What is Warehouse Order Picking?

Warehouse Order Picking is the process of getting specific items for a customer’s order.

This way, we can prepare the items and ship them, as soon as possible. In order to add value and customer satisfaction to our business, this process needs to be without any errors. The in-warehouse process is, most of the time, a key element to evaluate if your supply chain is working correctly.

Why is Warehouse Order Picking Important?

There are two words that define why warehouse order picking is important to any business: the first one is risk and the second one, value. Not getting an order right, or not getting it on time, might cause way too many issues for our entire supply chain. It might delay processes, cause extra expenses on shipping, and decrease the trust from our partners and customers.

Consequently, if we invest in improving our warehouse order picking process, we can provide extra value to our supply chain and our customers. They might highly appreciate things like quicker results, a lower margin of error, or more secured items management; resulting in providing value. Any business that is aware of these elements is probably thinking about ways to take its warehouse dynamics to the next level. For this reason, order picking is one of the main areas to begin with.

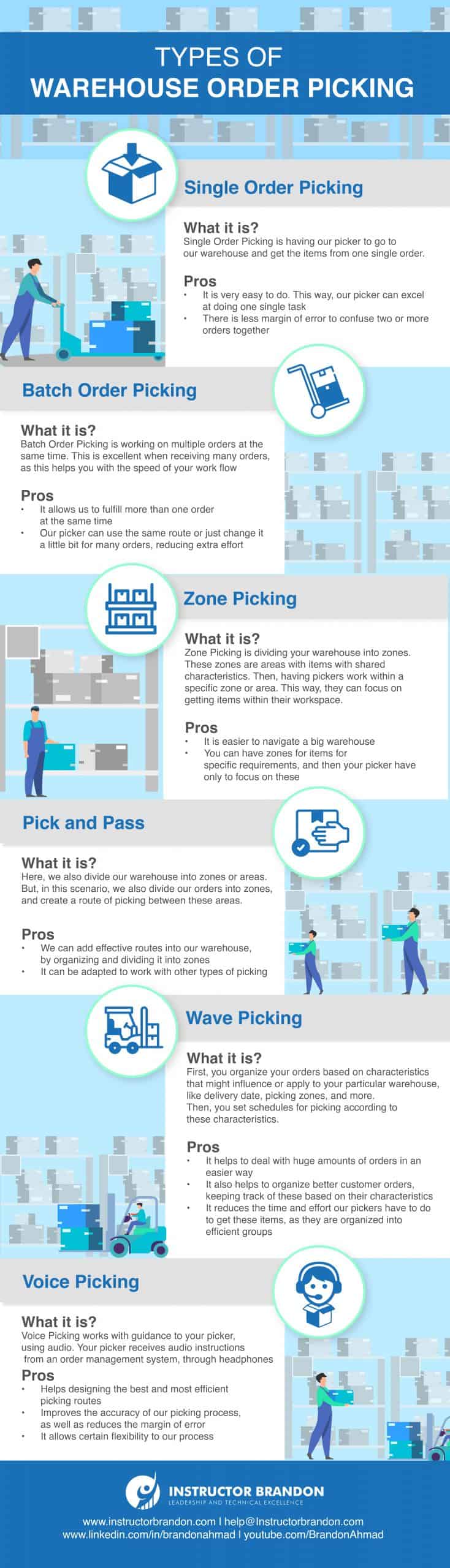

Types of Warehouse Order Picking

Depending on what you value the most when it comes to warehouse management, there are various types of warehouse order picking. You can choose and adapt to them, considering what your business needs the most at the moment. Constant evaluation of your needs and processes might help a lot with this. Here are some of the best and most used warehouse order picking types that might help you improve your inner practices:

1. Single Order Picking

This is probably the most used type of order picking.

Single Order Picking is having our picker go to our warehouse and get the items from a single order. This sounds easily doable and most of the time, for starters, this is the first method that companies are comfortable using.

2. Batch Order Picking

On the other hand, we have the opposite of Single Order Picking: Batch Order Picking.

In this case, we work on multiple orders at the same time. This is excellent when receiving a lot of orders, as this helps you with the ‘speed’ of your workflow.

3. Zone Picking

Now this one works with a whole different strategy.

Zone Picking is dividing your warehouse into zones. These zones are areas of items with shared characteristics. Maybe you have a zone for heavy items, or maybe you have one for refrigerated produce?

The way this works is by having pickers work within a specific zone or area. This way, they can focus on getting items within their workspace. In the end, they all place those items at a shared space, or they pass them through their zones until they reach their way to our end customer.

4. Pick and Pass

This one is a bit similar to the previous one, except that here, we work with a flow.

With a Pick and Pass type of picking, we also divide our warehouse into zones or areas. But in this scenario, we also divide our orders into zones and create a route of picking between these areas. For example, if we receive an order for items from zones A, C, and D, our picker can go to zone A, and get all the items from that specified area. Then, they can pass to zone C and do the required picking. After this, they pass to zone D, until they have all the required items our customer needs.

5. Wave Picking

This one works for warehouses with a high flow of customer orders.

With Wave Picking, you first organize your orders based on characteristics that might influence or apply to your particular warehouse: like delivery date and picking zones. Then, you set schedules for picking according to these characteristics. Let’s say, for example, that you received twenty orders this morning; from which fifteen have items from zone A, sixteen have items from zone B, and five have items from zone C. You could make a schedule to go and pick items from a specific zone, also known as a wave.

6. Voice Picking

This is another idea you can combine with other types of order pickings.

Voice Picking works with a guidance technique for your picker, using audio. Your picker receives audio instructions from an order management system, through headphones. This way, your system lists the items your picker has to get, plans the best routes, and provides real-time information for where the required items are.

Pros and Cons for Warehouse Order Picking Systems

Pros and Cons of Single Order Picking

Single Order Picking has some benefits for sure, but also some disadvantages that we are going to explain now:

Pros of Single Order Picking

- It is very easy to do; the strategic effort is reduced to the minimum. This way, our picker can excel at doing one single task

- Because of the dedicated attention to a single order, there is less margin of error to confuse two or more orders together. The picker easily understands what a single order’s items they need to look for

Cons of Single Order Picking

- Because our picker is dedicating all the effort to a single order, it could take longer to work on the following orders; in case there is more than one order at the moment

- Also, because your organization works on every order separately, our picker would have to do similar or sometimes even the same route in our warehouse, more than once. This could end up being extra work with little to no performance retribution

Pros and Cons of Batch Order Picking

As Batch Order Picking goes to the next level in management and procedures, its pros and cons change; and we need to talk about them:

Pros of Batch Order Picking

- The main one, of course, is that this technique allows us to fulfill more than one order at the same time, reducing the time we take to do so

- Our picker can use the same route or just change it a little bit for many orders. Maybe he has to pick items from two different orders in the same zone of your warehouse. With this technique, he can do so at the same time, reducing the effort of walking to the same place over and over again

Cons of Batch Order Picking

- Because we are working on multiple orders side by side, the chances of mixing or confusing two different orders might increase. So, you should have in mind that you need to take care of your strategy when using this order picking method

Pros and Cons of Zone Picking

This type of picking has benefits and disadvantages of its own, and we are going to mention them here:

Pros of Zone Picking

- It helps divide a big warehouse into smaller areas. So, these are easier and quicker to navigate and manage

- If you have different requirements for stocking or picking, you can take advantage of this method too. You can simply have zones or areas for these items (for specific requirements), and then your picker will only have to focus on these

- Your pickers will be focused on just getting certain items, so there are fewer chances for mixing or confusing orders

Cons of Zone Picking

- It might increase the cost of personal expenses because you would need to have at least one picker per zone or area

Pros and Cons of Pick and Pass

Now, let’s go over some of the pros and cons for this type of picking:

Pros of Pick and Pass

- This is great to add effective routes into our warehouse, by organizing and dividing them into zones. This way we will only go to those areas we actually need to go to

- It can be adapted to work with other types of picking. So, you can get both the benefits from this type and from another one that you choose

Cons of Pick and Pass

- One of the main issues here is that you would need to be constantly making new routes based on new customer orders. This is, however, possible if you have a warehouse management software or tool to help you out

Pros and Cons of Wave Picking

Well, Wave Picking is very easy to apply, especially if you have warehouse management software to help you with schedules and more. So, we should go over the pros and cons for better understanding:

Pros of Wave Picking

- It helps to deal with huge amounts of orders in an easier way. Managing smaller amounts of these could make the whole process quicker and more precise

- It also helps to organize better customer orders, keeping track of these based on their characteristics

- It reduces the time and effort our pickers need to get these items, as they are organized into efficient groups. This way, our pickers only have to go to a certain zone of our warehouse when necessary, particularly when a wave arrives

Cons of Wave Picking

One disadvantage wave picking might have is that it is too strict and not so flexible when it comes to emergency orders. Let’s say, if you ever have a customer order that you need to pick immediately, wave picking might not help too much in that case. This is because you would have to wait for the next available wave you could add this order to. And if it is an emergency, you might need that order before the said wave

Pros and Cons of Voice Picking

This is a highly technology-based technique, but it is definitely useful and worth the investment, as we will see with its advantages:

Pros of Voice Picking

- Voice Picking’s software helps design the best and most efficient picking routes for our warehouse. All of this is possible, thanks to the data-based analysis

- Having constant guidance improves the accuracy of our picking process, as well as a reduction in the margin of error. This helps our picker focus on his main task while letting the software plan other side requirements

- Being real-time-based allows certain flexibility to our process, as things might suddenly change. In this case, we are able to respond quickly and keep the workflow going

Cons of Voice Picking

- Definitely, the biggest aspect to have in mind with technology-based picking methods is the cost of investment. Of course, having the tools and professionals to set and manage them might increase the costs in our warehouse.

However, if you think It might bring more benefits to your supply chain, then it might be worth thinking about!

How to Do Order Picking in Microsoft Dynamics 365?

Sales Order Picking in Dynamics 365

The process to manage picking orders in Microsoft Dynamics 365 is rather simple. All you have to do is the following:

- Create a sales order for an invoice account and then specify site and warehouse for the storage dimensions

- Add sales order lines with your items

- From the sales order lines header, proceed to inventory; then reservation to reserve items

- To release sales order lines to the warehouse for picking, go to warehouse; then release to the warehouse

- From the line header, proceed to warehouse; then work details

However, if you are looking for more details to know about this process fully, you can check our article here.

Last Considerations: Order Picking Methods in Warehouse

At the end of the day, there are a couple of things you should consider before adding one or many order picking methods to your warehouse management. Each business is unique, and every team has its own strengths. So, nobody knows what is best for your company, other than you. It would be great for you to take a moment and think about these aspects of your business:

1. Safety

Is there a way you can keep or improve the safety of your team when working with warehouse picking? There is nothing like a safe space to work in.

2. Team

Is your team available and ready to get the most out of any of these order-picking methods? Or else, would it be necessary to add some training for certain skills and procedures?

3. Warehouse Size

How big are your warehouses in terms of space, aisles, and possible routes? Also, consider how organized it is, as it could also influence your picking process.

4. Order Volume and Size

How many orders do you usually get on a daily basis, and what is their size? These aspects could represent a decision-making element to choose picking methods.

5. Product’s Physical Size

And finally, what is the size of the products and items you manage in your warehouse? Is it even possible to handle five, ten, or twenty of them for one single person? That could also play a key role in what picking type to choose.

Conclusion: Warehouse Order Picking Methods

In conclusion, you are not alone: there are plenty of options for you to choose from and improve your order picking process with efficient methods.

Whether you use traditional methods, technology-based, or both; you should always think about how well they could adapt to your unique warehouse and team, and what value they could bring to your supply chain. Of course, there are many tools and software developments that could help you with these tasks. For example, Microsoft Dynamics 365 not only has an option for warehouse management but for every single step in your entire supply chain.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is warehouse order picking?” answer-0=”Warehouse order picking is the process of extracting products from a warehouse based on customer orders. To learn more about them, keep reading this blog post. ” image-0=”” headline-1=”h2″ question-1=”Why is warehouse order picking important?” answer-1=”Imagine the kind of issues a company would face if they can’t get an order right. Warehouse order picking plays a fundamental role in a company’s supply chain. Learn more about why it matters by reading this blog post. ” image-1=”” headline-2=”h2″ question-2=”What are the types of warehouse order picking?” answer-2=”A business’ supply chain may require different types of picking. There are six total and they range from single order picking to voice picking. To learn more about each type of warehouse order picking, keep reading this blog post. ” image-2=”” headline-3=”h2″ question-3=”How do I choose a warehouse order picking method?” answer-3=”Before you choose one or multiple warehouse order picking methods, there are a few things you should consider to ensure you get the best out of them. Click on this blog post to find out more. ” image-3=”” count=”4″ html=”true” css_class=””]If you are interested in bringing these benefits to your company, through real world-based training and hands-on laboratories; we, at Instructor Brandon Inc., have many options available for you.

Feel free to contact us and we will share how you can get a huge advantage in today’s competitive market with business management software. If you are interested in learning more about Supply Chain Management and Data Visualization, visit our blog. This has been Brandon Ahmad, see you next time!

8224

8224