Supply Chain and Logistics Management

Optimizing Inbound Logistics & Integration with Dynamics 365

In the value chain inbound logistics play an important role.In itself, is the process in which companies do different activities and tasks. This with the objective of ensuring a correct service at the lowest possible cost. Therefore, it is essential to recognize the important of inbound logistics in the management of organizations. It is a complete process of complex actions that will allow us to successfully carry out the entire supply chain.

Of course, any company, regardless of its size, must have inbound logistics processes continuously optimized and improved through emerging technologies; designed specifically to streamline said processes. The more efficient inbound logistics department is, the more advantages and benefits a company will obtain with respect to competition.

What is Inbound Logistics?

Inbound logistics process is, by definition, the part of logistics in charge to the organization of material and information flows that occur within a company. It means, in simple words, the movement of assets inside a warehouse and the control of stock.

The main function of inbound logistics is to provide all operating units of the company with necessary supplies on time. This task required other functions that, together, fulfill the objectives of a company to function properly.

What Are The Major Functions In Inbound Logistics?

The most important inbound logistics functions are:

Inbound Transportation

Without transport, there is no movement; and without movement no product arrives at its required destination. Transport management system in a company’s inbound logistics is an essential factor; without it, the movement of products already manufactured and prepared for sale and consumption would not be possible.

Transportation of assets is one of the most important economic activities for a business, since it allows moving goods from their initial place to where they have to be sent. It is a fundamental service that links the company with its suppliers and customers; making it as essential activity in logistics and the Supply Chain itself.

Furthermore, by working closely with inventory managers, transportation professionals aim to ensure that the company has products available at the right location & time where customers seek them.

Inventory

Inventory control ensures that the logistics process as a whole works properly. The cost of inventory control operations is higher because it takes up more space and requires the purchase of equipment and facilities.The company controls and values at all times the stock of goods in warehouses, making sure that inventory contemplates the failures and successes

In addition, there must be a rigorous control of possible risks and inconveniences in this department, such as accidents at work, lack of materials, raw materials or the lack of transport. Once the problem has been analyzed and possible solutions investigated, employees can access the inventory and contingency plan to solve the problem quickly.

Raw Materials

Internal logistics must work efficiently to ensure that all raw materials are used and no major losses are incurred. With this, the cost of raw materials is adjusted and the transport/storage costs are reduced in an effective manner.

On the other hand, if production systems are implemented at the right time, raw materials and manufactured products will always be available when they are needed. This results in a reduction of inventory costs and a better relationship between the company and suppliers of raw materials.

In addition, there are other functions that are also performed by inbound logistics, such as:

- Procurement and Purchasing: Order and acquire the material and raw materials needed to produce the product, as well as monitor the delay in the processes.

- Storage: The operators locate, preserve and handle the goods during the time they remain in the company.

- Packaging: Packing the products as well as maintaining quality controls.

What Is The Difference Between Inbound Logistics And Outbound Logistics?

Many business functions fall into the category of logistics, including functions such as fleet management, warehousing and materials management. However, the concept of logistics is generally divided into inbound logistics and outbound logistics.

Inbound logistics covers the transportation and storage of goods coming into the warehouse. Typically, this includes the relationship between a warehouse and its suppliers of raw or semi-finished goods.

In contrast, the outbound side refers to the transport of goods leaving the warehouse. This covers the relationship between a warehouse and its customers.

What do we achieve with the right Inbound Logistics strategy?

With the right Inbound Logistics Strategy, you gain the following benefits:

- Valuate the goods using the most appropriate method for each situation

- Control, order and organize the assets.

- Manage the warehouse efficiently

- Determine the materials needed

- Define the human resources

With this intention, organizations must work towards continuous improvement as it helps them increase efficiency and gain competitive advantage with the right Inbound Logistics Strategy.

Innovation as a Competitive Advantage:

Companies are evolving globally and introducing innovations in the area of inbound logistics. In order to do so, they change the tradition vision of its functionality. Many companies are now more open to automated processes, resulting in a reduction of costs, increasing productivity and minimizing errors.

In fact the rise of digitalization and its relationship with increasingly intelligent machinery has had a significant impact on the organizing of internal logistics; companies are now seeking to lessen their logistics expenses.

Some of the elements that companies can automate in their internal logistics include transport, distributors and storage system.

Let us look into the main trends that are modulating Intra-Logistics processes:

Strategic Planning Of Internal Logistics in a 4.0 Environment

Internal logistics planning becomes a discipline of precision, in which it is necessary to align production and storage operations. This involves integrating the work of various departments that influence the management of internal logistics: purchasing, marketing, storage and production.

For this reason and in the face of such data management, the information flow is divided into differentiated software but they work together and add layers of specialization.

As an example, the production module for the WMS provides interesting functionalities for handling raw materials and semi-finished products, in addition to the finished products that are already controlled from the WMS base (in conjunction with the ERP).

This kind of specialization provides greater integration of all the company’s Intra-Logistics processes. On the other hand, the need to adapt layout and storage systems to maximize the storage capacity is maintained. Declining margins and increasing competition have made approaches such as ‘Lean Logistics’ more popular for the organizing of Intra-Logistics.

Automation of Handling & Inbound Transport of Assets

Movements or cargo movements represent a significant percentage of Intra-Logistics costs. The way that this material flow is executed has undergone important advances and transformation in recent years, with the massive implementation of automated systems such as stacker cranes and conveyors.

For this reason, the automation of warehouses gives great results to those facilities that register a high volume of operations and whose layout is repeated over time; it ensures that the investments will be long-lasting.

For this reason, pallet and heavy load warehouses are the ones that have led the change towards automation.

In the case of manufacturing companies, warehouses attached to production plants usually comply with these premises, since the flow of loads is marked by high-volume manufacturing, which is controlled by the company. These facilities must be capable of absorbing all production by adjusting the way they operate, so that the goods do not stop flowing.

However, the growth of online businesses has meant that, in many cases, these companies have had to adapt to logistics for e-commerce. To do so, they also resort to the implementation of automatic systems in order to accelerate the processing of packages and boxes of smaller size and weight.

Use of Collaborative Robotics in Picking and Packing Operations:

Although it may seem like the opposite; in robotic warehouses, machines and operators work together dividing tasks. The more repetitive and heavy ones fall on the former and the more specialized ones are entrusted to the latter.

The operators are at the epicenter of the internal logistics; they are the ones who make it possible for the warehouse to continue working at full capacity.

Advances in Intra-Logistics also take into account safety and ergonomics of the work being executed. Collaborated robots (cobots), such as mechanized arms or packaging machines, discharge some of the physical effort in picking and packing tasks to limit fatigue as much as possible.

Similarly, the workload of the workforce is controlled and distributed equally by Labor Management Systems in conjunction with the WMS to avoid overloads and productivity problems linked to poor work organization.

Warehouse Control by WMS and IOT Technology:

Connectivity between systems has accelerated Intra-Logistics flows, thanks to the implementation of warehouse management software. This allows for the control and registering of movement of goods between a company’s facilities, ensuring traceability.

In this way, the WMS organizes tasks related to the reception of goods, picking and preparation of orders and the dispatch of final products.

The presence of interconnected devices in the warehouse management (IOT technology or the Internet of things) is essential to carry out the transfer of information from the real environment to the digital environment. For example, these systems can be tablets (Pallet Shuttle), headsets (voice picking), radiofrequency terminals or illuminated buttons (light picking), among others.

Also these interconnected systems are responsible for channeling the orders from the WMS to the operators and the automatic systems (there is a direct communication between the control software and the management software).

They are designed to accompany the operator in the execution of the picking; an area that groups together most of the operating weight of any installation. For the internal logistics of a company to function properly and become a strategic pillar, there must be coordination of all functions.

How to Optimize the Inbound Logistics Process:

Experts consider the inbound logistics process “the final frontier” for companies that wish to reduce transportation costs. Streamlining this process is difficult and requires considerable effort from supply chain managers and warehouse operators. At a higher level, improving inbound logistics includes the following activities:

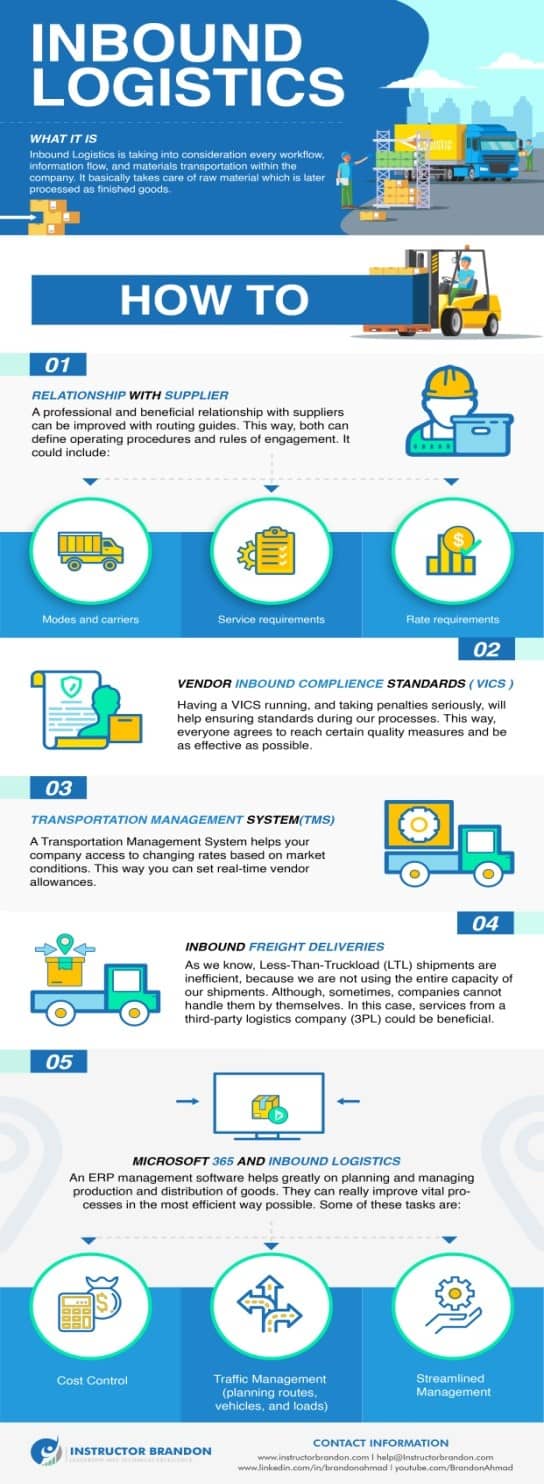

Building Strategic Relationships with Your Supplier Partners

Determine your most optimal route and work with suppliers to implement it in a way that’s beneficial for both parties. Create a routing guide to define operating procedures and rules of engagement. Your routing guide should include:

- Modes and carriers to use in certain lanes

- Rate requirements

- Service requirements

While routing guides can be physical or digital, experts recommend online routing guides. They can adapt to changes in the shipping landscape, such as fluctuating rates. By implementing a routing guide, you can limit rogue expenses by suppliers.

For instance: it introduces rate benchmarks and eliminates the use of non-authorized carriers. Naturally, though, a routing guide is most effective when a particular individual or business unit is in charge of overseeing and updating it.

Developing and Implementing Vendor Inbound Compliance Standards (VICS)

Specific supplier behavior hinders a company’s ability to manage a streamlined and efficient value chain management. A company needs to develop Vendor Inbound Compliance Standards (VICS) so that all suppliers agree to rules and regulations. By reinforcing positive behavior and establishing penalties for negativity, you can optimize your inbound logistics processes.

Keep in mind though, that it isn’t enough to just develop VICS. Non-compliance requirements and financial penalties that would offset the cost of inefficient practices must result in penalties.

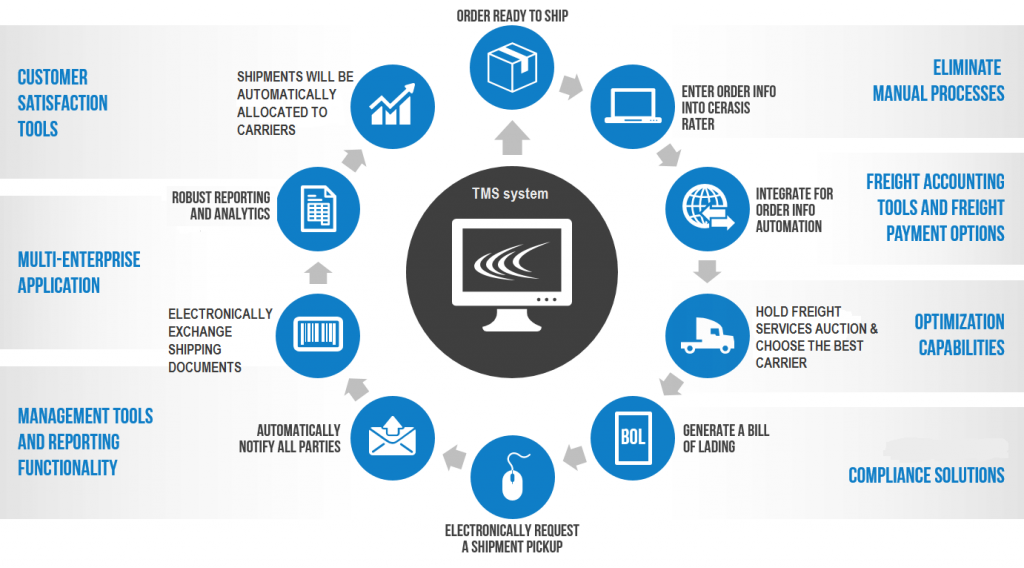

Using a Transportation Management System (TMS) for Dynamic Rates of Freight Costs

Businesses often accept the freight costs their vendors quote due to the lack of visibility of market rates. With a transportation management system (TMS), your company has access to changing rates based on market conditions. You can use this information about carriers and routes to set real-time vendor allowances. This ensures that you get the best rate possible and keep costs low.

Consolidating Your Inbound Freight Deliveries

Less-than-truckload (LTL) shipments are inefficient and lead to unnecessary costs, both in terms of shipping and unloading. When a company unloads 10 to 14 different LTL shipments, it spends 5 times more than it would upon unloading just one truckload.

By consolidating LTL shipments into full truckloads, your company saves money. Of course, there are challenges associated with this strategy, especially when working solo.

To reap the benefits of full truckload transportation, you have to think about the following logistics considerations:

- Specific shipping and handling requirements

- Point of origin and final destination of shipment

- Shipment weight

- Departure time and arrival time of shipments

- Availability of drivers

- Availability of trucks

- Current fuel costs

Sometimes companies cannot pull off a full truckload inbound transportation strategy on their own. In such cases, they use the service of a third-party logistics company (3PL).

How do I implement Microsoft Dynamics 365 Technology in my Inbound Logistics Strategy?

The ERP management software for transport/logistics companies of Microsoft Dynamics 365 Supply Chain Management (Navision) offers integrated functionality to plan and manage production and distribution, specifically for companies engaged in processing goods.

This solution supports a wide variety of manufacturing processes such as production to order, production to stock with process and discrete manufacturing operations.

Today, most companies have chosen an ERP management system that allows them to optimize their processes and manage different departments of a company in an integrated manner. Having ERP software for transport and logistics is vital to ensure the competitiveness of the company, as it improves not only the management processes but also the margins obtained from each service.

Achieving competitive rates and controlling the profitability of shipments is the main objective of a company, and for this purpose, three fundamental pillars must be taken care of:

- Optimization in traffic management (planning of routes, vehicles and loads)

- Cost Control

- Streamlined management

Microsoft 365 offers you ERP management software that gathers all the functionalities required for your logistic and operative processes. It ensures a flexible and scalable solution that allows your business to evolve with the greatest guarantee of competitive advantage.

With this ERP system for transport and logistics, your company would be able to achieve success thanks to the precise control of orders, fleet management, rates, surcharges and shipment planning. You can be able to build a Dynamics 365 Supply Chain Management and improve your company.

Also if your business has delegations, it allows for communication in real time; streamlining management and increasing the quality of service and customer satisfaction.

We recommend that you explore all the program, course and certification options offered by Microsoft, so that you are aware of new technologies and options for your business and career growth.

Improving Inbound Logistics, an Important Part of Effective Supply Chain Management:

At Instructor Brandon we know that a strong inbound logistics process ensures that businesses are working with the best suppliers; while an effective outbound process keeps customers happy, resulting in more sales.

Keep a careful eye on your workflows and develop standard operating procedures to increase efficiency. Do not be afraid to use technology to gain visibility over your entire supply chain.

By prioritizing supply chain management, regardless of the size of your organization, you can adapt the strategies and techniques that work well for your business. If you want to know more about the processes that can be carried out with the different Microsoft software, visit our blog post and find out all the news.

The balance between resources the company obtains and the demand of clients will allow for a competitive advantage in the market. If you have any questions or want to learn how to use these new technologies in your company, do not hesitate to contact us.

4032

4032