Supply Chain and Logistics Management

How to Optimize Outbound Logistics With Dynamics 365 SCM?

Managing logistics is a complex and costly task when you do not have an effective supply chain management system. Logistics are the foundation that sets how your business turns raw materials into products and how these products get to your customers. While many business owners understand the key role logistics play in the success of their operations, they do not always have an understanding of their logistics processes as a whole. As a matter of fact, bringing materials to your company and delivering finished products to consumers are two separate facets of logistics.

These are known as Inbound Logistics and Outbound Logistics. Knowing the difference between them is crucial if you want to have a full understanding of your logistics network. For that reason, we are going to dive into the ins and outs of outbound logistics in this article. That way you can learn why they matter, and how they differentiate from inbound logistics.

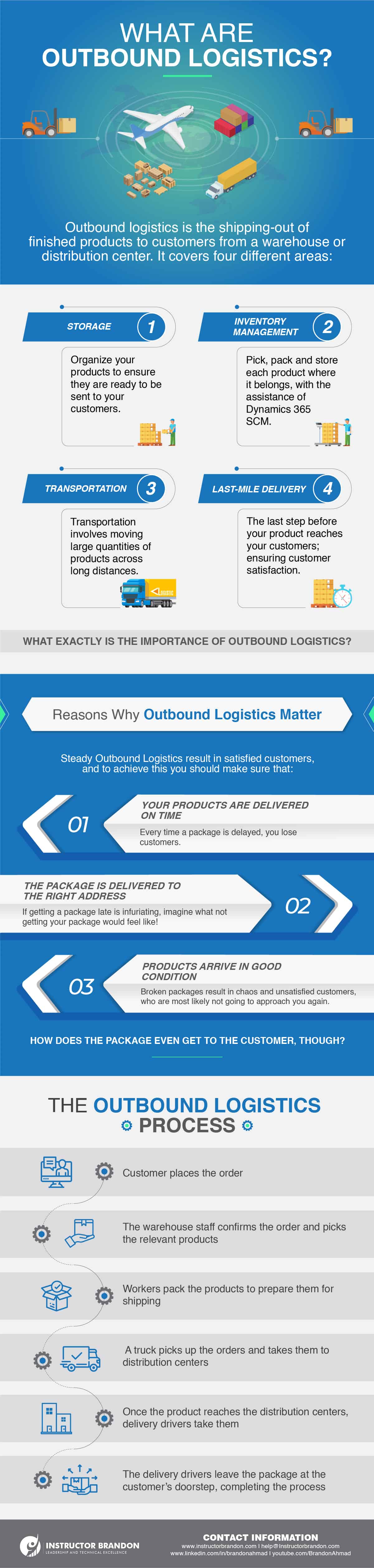

What is Outbound Logistics?

Outbound logistics in supply chain management refers to the transportation, storage, and delivery networks that businesses use to bring their products to their customers. In other words, outbound logistics are the links between your finished products and their destinations.

Outbound logistics are centered around four areas:

- Storage

- Inventory management

- Transportation

- Last-mile delivery

1. Storage

Storage in outbound logistics revolves around using warehousing techniques to keep the products safe and accessible. Since the company is likely to send out products to customers at any moment, proper organization is fundamental. Bear in mind that to continue meeting demands as you make sales, you need to keep a steady supply of products in your storage. In November last year, companies in the US had an average ratio of 1.32 inventory to monthly sales, which allowed them to stay ahead of customer demand.

2. Inventory management

Inventory management is what we call the process of picking, packing, and storing your products where they belong. Most companies use the assistance of inventory management systems to ensure everything goes smoothly.

3. Transportation

Most business owners deem transportation the most complex area of outbound logistics. After all, moving large amounts of product across long distances can be challenging. Transportation covers the process of sending or shipping products to distribution centers or partners. Companies use trucks, planes, and freights to move their products from one location to another most conveniently and efficiently.

4. Last-mile delivery

Since it is the step that establishes a connection between your product and your customers, last-mile delivery is very important. This is when your product goes from the distribution center or warehouse to your buyers. It is also a subset of transportation, as it is usually handled by fleets of smaller trucks or vans.

In short, to ensure customer satisfaction you have to effectively cover each one of these areas. Just think of Amazon’s same-day delivery service, and how failing to successfully cover any of these steps would result in a customer not getting what they ordered. It would be bad, right?

Why is Outbound Logistics Important?

It all comes down to exceeding customer expectations. Keeping customers happy is the best way to keep your business going, as such, paying close attention to outbound logistics ensures you have better returns long-term.

By keeping a close eye on your outbound processes you can ensure that:

- Your products are delivered on-time: It is 2021 and considering how many big companies have mastered prompt deliveries, you cannot afford to stay behind. Every time a package is delayed, you lose customers

- The package is not delivered to the wrong address: Not only does mishandling packages result in late deliveries, it also makes it so packages do not reach customers at all

- Products arrive in good condition: While it is true that late packages do not make customers happy, receiving a broken package is an even worse experience

Now that you know the basics of outbound logistics, let us do a quick overview of the outbound logistics process.

What is the Outbound Logistics Process?

At a surface level, the outbound logistics process is pretty simple. It begins right after the customer places an order, and it goes as follows:

- The warehouse confirms the order and the workers pick the relevant products. If the company uses warehouse management software, it adjusts the number of products available based on their ID or stock-keeping unit

- The workers pack the products and move them to the loading docks to prepare them for shipping

- The trucks pick up the orders and take them to the closest distribution centers to the customer

- Once the products arrive at the distribution centers, delivery drivers pick up the products to take them to their respective delivery area

- The delivery drivers leave the package off at the customer’s doorstep, completing the process

As you can see, inventory systems, channels of distribution, and delivery optimization play a key role in the process to ensure the customer receives their product.

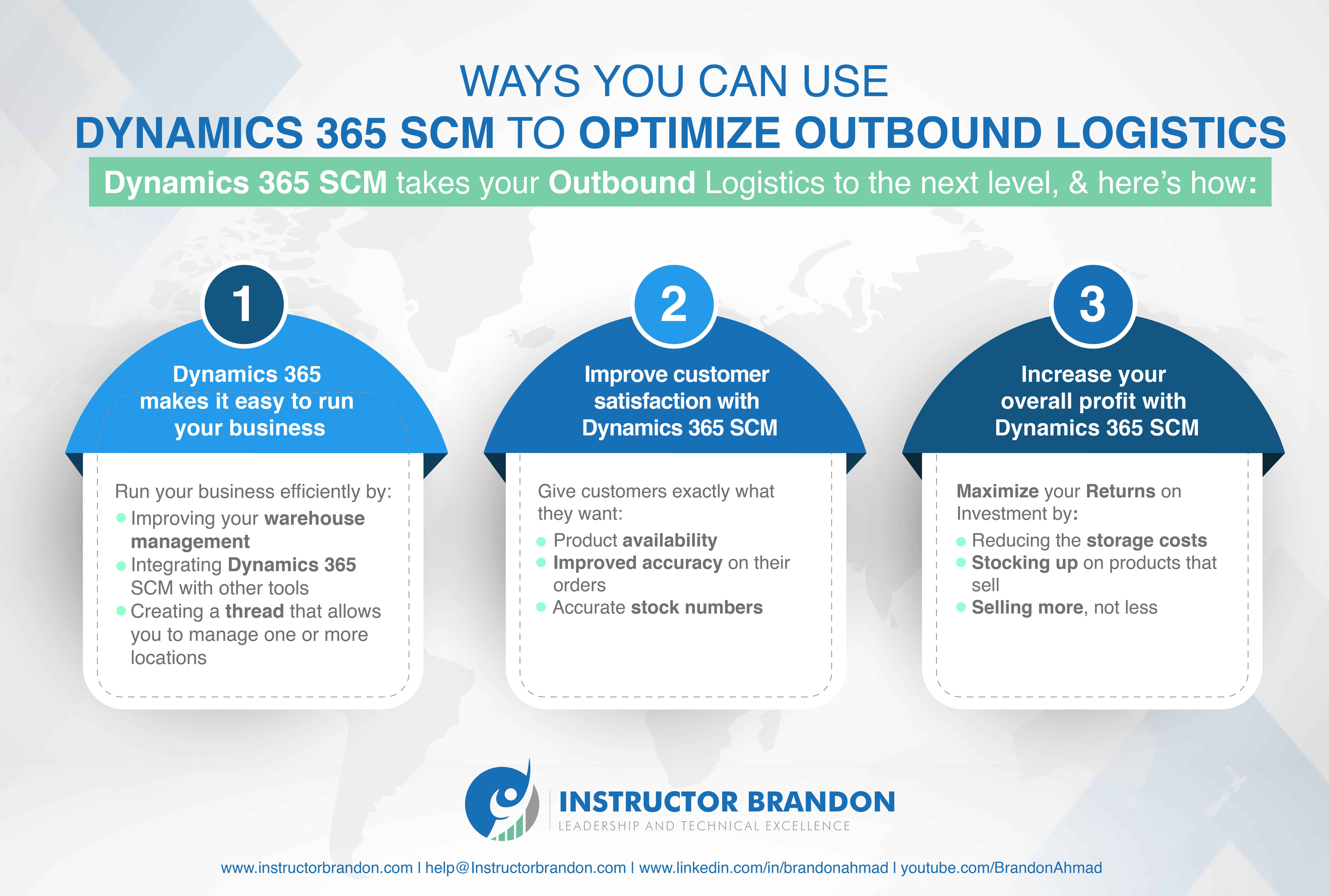

What are the Benefits of Optimizing Outbound Logistics With Dynamics 365?

Effective inventory management affects every single aspect of your business. Unfortunately, it is a difficult process to do by hand. Not only does it take time, but any mistakes could have ripple effects that negatively impact your business long-term. Fortunately, tools like Dynamics 365 Supply Chain Management (SCM) exist, allowing business owners to automate their manufacturing and inventory tracking process. With that in mind, let us dive into how Dynamics 365 SCM can optimize the inbound and outbound logistics processes of your company for your benefit.

The benefits are the following:

- Dynamics 365 SCM makes it easy to run your business

- You can improve customer satisfaction with Dynamics 365 SCM

- Increase your profit by using Dynamics 365 SCM tools

1. Dynamics 365 SCM makes it easy to run your business

Dynamics 365 SCM includes other tools to make your business run even more efficiently. Here are a few examples.

Improve how you manage your warehouse

With its warehouse management features, Dynamics 365 SCM can help you improve order accuracy. But it also helps you streamline efficiency within your warehouse. Dynamics 365 SCM helps you map your warehouse space, helping you find the most cost-efficient, easy-to-use system. You can also integrate ID or barcode scanning so you get real-time updates on stock levels and inventory movement. All that helps you minimize guesswork and get a more accurate picture of your inventory situation when you need it.

Manage one or more locations

Dynamics 365 SCM can help you manage inventory storage and stock levels between multiple warehouses or locations. It also integrates supply chain logistics features, allowing you to order products for all your locations in bulk while moving products between locations based on need. You never lose track of where any item is at any given moment.

Integrate Dynamics 365 SCM with other tools

Finally, Dynamics 365 SCM integrates with many other business processes:

- Point-of-sale (POS) systems: To track sales and stock levels in real-time and assist with product forecasting

- Accounting systems: To gain more accurate forecasting metrics and find the most economic order quantities for product stocking

- Customer relationship management (CRM) systems: To link order fulfillment with service requests and customer interactions

To learn more about how to integrate Dynamics 365 SCM with other tools, check out the modules in our MB-300 course, where we offer a thorough overview of the basics of software integration.

2. You can improve customer satisfaction with Dynamics 365 SCM

Have you ever tried to buy something only to find that the product you want is out of stock? Or waited for weeks for a product to arrive? Or opened a package only to discover that the item was damaged or the wrong item altogether?

None of these experiences paint your business in the best light, and they can all negatively impact customer loyalty. Fortunately, Dynamics 365 SCM can help minimize these mistakes and deliver the best possible experience for your customers.

Ensure products are available at all times

Solutions like Dynamics 365 SCM includes forecasting and automated reorder protocols. This improves the likelihood that you will have enough product on your shelf when your customers want it, which in turn improves the chances that your customers will find the exact items they need.

Improve the accuracy of customer orders

Warehouse management is also a key feature of Dynamics 365 SCM. This feature helps you maintain an organized warehouse, which reduces the risk that you will simply shove new inventory into a random spot, forget it is there, and lose track of your merchandise. It also helps warehouse employees pull items for customer orders with greater accuracy, so your customer actually gets what they ordered. It also includes logistics features that help you track order fulfillment time. That way, you can give your customers an accurate delivery estimate.

Keep tracks of your sales across multiple channels

Whether your business runs on a set location or an online store, it can be difficult to make sure every customer order gets processed accurately while also ensuring your physical store locations have enough inventory on hand. Dynamics 365 SCM makes this process a lot easier. It can integrate with your POS system to track sales and stock across multiple channels all in one place. That way, you can manage your business’ inventory as a whole instead of on a case-by-case basis.

3. Increase your profit by using Dynamics 365 SCM tools

Maintaining a stock relative to your sales can be risky. Fortunately, Dynamics 365 SCM can help you minimize risk and streamline your costs, which ultimately means a healthier bottom line for your business.

Reduce the costs of storage

Dynamics 365 SCM includes basic economic order quantity calculations, helping you identify the most cost-efficient method for ordering new products by weighing the costs of storing your products versus the cost of ordering your products. This process happens automatically, so you can minimize your warehousing fees and save money.

Avoid losing money

Products that do not sell are essentially losses to your business. After all, you have already spent the money to make the items, but you cannot recoup that capital by selling the product. Dynamics 365 SCM helps minimize this risk because it includes forecasting. Forecasting involves tracking the number of units you have sold and estimating the number of units you will sell in the future. Even with an automated, computerized tool, forecasting is not 100% accurate. But using Dynamics 365 SCM to do the math for you is still more accurate than trying to crunch the numbers yourself.

Dynamics 365 SCM can also integrate it with a point-of-sale system to update your stock numbers in real-time. That gives you more accurate projections, which lowers your risk of investing too heavily into products that will not sell. Also, Dynamics 365 SCM can calculate the exact number of units you need to order and recommend the ideal time to place your order.

Sell more, not less

If you do not have enough products in stock to meet demand, your customers probably will not come back later. Even a single lost sale may represent thousands of dollar’s worth of lost potential sales, so it is important to have enough stock to meet customer demand. With Dynamics 365 SCM, you are more likely to have the right products on hand at the right time to meet customer demand. This helps you sell more in the here and now, but it also helps you secure customer loyalty so you can sell more products in the future.

Last Considerations: Improving Outbound Logistics With Dynamics 365 SCM

Even though the outbound process is straight forward, it shares a few similarities with the inbound process. That sometimes confuses those wanting to get a grip on the logistics of their company. With that in mind, let us show you how you can tell them apart.

Key Differences Between Inbound and Outbound Logistics

Outbound logistics are very different from inbound logistics, which is why it is helpful to separate them. The primary difference is that inbound logistics are meant to bring in a steady supply of materials to fulfill your operational needs, while outbound logistics are designed to bring out your products to your customers. Since inbound logistics are an internal process, they do not need to keep up with consumer expectations the way outbound logistics do.

Ordering and receiving products are no longer what they used to be. For that reason, consumer expectations are always changing and in the look for something better. If you promise one-day shipping, you have to get the product to the client’s door in that time frame. Otherwise, you risk losing business.

Conclusion: Optimize Outbound Logistics with Dynamics 365 SCM

Overall, optimizing your outbound logistics ensures that customers are satisfied, resulting in more sales and overall profitability. Keeping an eye on your internal workflows to create the product is just as important as overseeing their delivery. To learn more about the tasks you can successfully carry out with top-notch inventory management software, stay tuned for our next post in the Supply Chain Series.

Thank you for reading our blog post on How to Optimize Your Outbound Logistics With Dynamics 365 SCM. If you found this article helpful, let us know in the comments below. Moreover, you can contact us here to learn more about the benefits of Dynamics 365 Supply Chain Management. This has been Brandon Ahmad, founder of Instructor Brandon and Dynatuners.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is outbound logistics?” answer-0=”It refers to the processes that ensure customers get your products. It covers four areas: storage, inventory management, transportation, and last-mile delivery. To learn more, continue reading this blog post.” image-0=”” headline-1=”h2″ question-1=”What is the importance of outbound logistics?” answer-1=”To keep your business thriving, you must ensure your outbound logistics are top-notch. Read more to find out how the effectiveness of your outbound processes reflects on your customers.” image-1=”” headline-2=”h2″ question-2=”What is an example of outbound logistics?” answer-2=”The moment you order a product the outbound logistics process begins. It has more steps than you think, so we are giving you a detailed step-by-step on this blog post. ” image-2=”” headline-3=”h2″ question-3=”How can you improve outbound logistics?” answer-3=”Technology has brought great ways to optimize your outbound logistics process, including software like Dynamics 365 SCM. Keep reading this blog post to learn how an inventory management solution can take your outbound logistics to the next level. ” image-3=”” headline-4=”h2″ question-4=”What is the difference between inbound and outbound in a supply chain?” answer-4=”Although both are part of the logistics process, they address different operations that are key to the success of your business. Learn how to tell them apart by reading this blog post. ” image-4=”” count=”5″ html=”true” css_class=””]

3704

3704