Supply Chain and Logistics Management

Understanding Inventory Consignment Process in Dynamics 365

Understanding Inventory Consignment Process in Dynamics 365

Understanding the Inventory Consignment Process in Microsoft Dynamics 365 brings a lot of opportunities for businesses. You have access to useful tools within this system.

Having beneficial partnerships is one of the core elements to make a business work. Working with experts grants you access to new and innovative solutions.

Luckily, the Information Technology Industry makes this only easier for us. When a new system takes over our lives, it develops a certain skillset or an asset. Moreover, those take our business to the next level.

Investing time and effort in a company’s methods and team’s expertise is the most rewarding investment for a business.

In this article, we talk about what Consignment Inventory Process stands for. Also, how it works, the benefits and objectives. Later, how Microsoft Dynamics 365 makes it easier to be included in a company’s processes.

We should, however, keep in mind that this is a technical practice. Then, it takes skills and an investment of time.

Let’s Go Over the Basis of Inventory Consignment Process

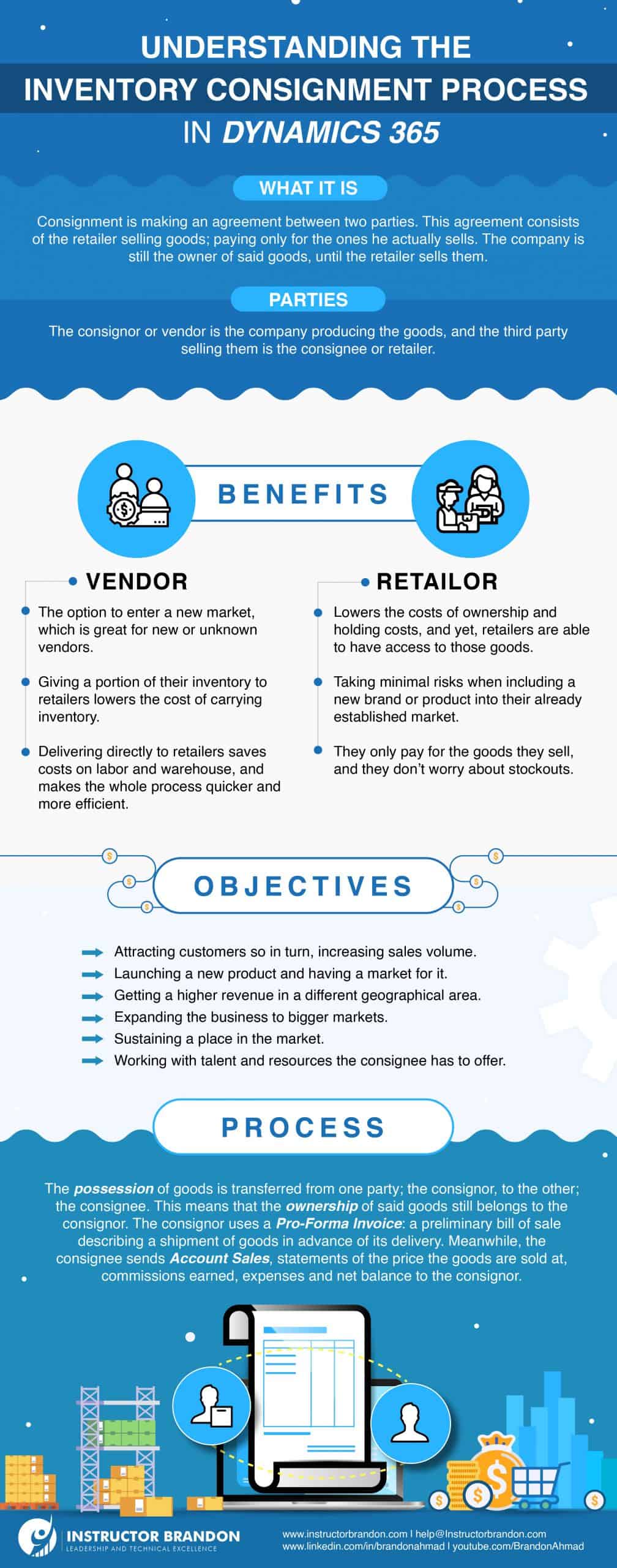

Let’s go over the basics first. A Consignment means making an agreement between two parties.

Here, two different companies agree to work together in a selling process. The goal here is to sell goods of one of the partners. Let’s define the two groups first.

Groups or Companies in the Inventory Consignment Process

There are usually two companies involved in this agreement:

- The Consignor: The consignor is the seller of goods. This company creates the products, or produces the raw materials.

- The Consignee: This group, depending upon the agreement, takes possession of these products or raw materials. Then, they sell or use them. Therefore, they only pay for the ones that they consume.

Explained in detail, it means that we (the consignor) work with the (consignee) to help sell our products. On the other hand, there is another option for us: to sell the product directly to the consignee.

The main aspect to have in mind, about consignment, is the ownership of the goods. Although the consignee takes possession of the goods, the consignor is still the owner.

Also, the consignee will only pay for the ones that are consumed, sold or used. In this alliance, the retailer takes the responsibility of selling our goods. Also, this means that they take care of the selling process.

Pros and Cons of Inventory Consignment Process

There are many pros and cons for both parties with a consignment. For this reason, it is worth mentioning them.

Let’s start with the pros:

For Consignors:

- They have the option to enter a new market. This is great for new or unknown vendors. Having access to the consignee’s already built position allows consignors to break through a new market.

- Giving a portion of their inventory to retailers lowers the cost of carrying inventory. This helps consignors to free some space at warehouses. Also, it allows them moving immediately a part of their production.

- Delivering directly to retailers saves costs on labor and warehouse. This makes the whole process faster too. Consignors avoid taking some steps that cost money, resources, time, and effort. In particular, costs of transportation to multiple destinies or extensive paperwork.

For Consignees:

- Lowers the costs of ownership and holding costs. Not to mention, they are still able to have access to those goods. This means that as long as the consignor has a stock on produced goods, they also have access to them. Also, they do not have to worry about the expenses.

- Taking minimal risks when including a new brand or product into their already established market. Since consignees only pay for the goods they actually sell or use. Of course, they do not have to worry about paying for unused goods. They do not have to pay for unused products or materials.

- They only pay for the goods they sell, and they don’t worry about stock outs. This means that they do not worry about making a huge investment on buying an amount of products. Instead, they only have to worry about paying for those that have already been sold.

For cons, these are some of the things you should take into consideration:

For Consignors:

- Facing the loss of goods that people do not buy or consume. Because the consignor is still the owner of those goods, those unused goods are still their property.

- Unmotivated consignees. They might be less motivated to make sales. Since, technically, they are not losing money and don’t have any risks to take. However, this is not always the case, and it can be discussed beforehand between both parties.

For Consignees:

- Wasting floor space with unused or non-consumed goods. This, at their back room or shelves.

- Being responsible of any damage or issue to those goods. Although they are not the owners, they still have to make sure those products or materials are safe and secure.

How does Inventory Consignment Process work?

Overview of the Inventory Consignment Process

Like any other agreement, a consignment takes place when both groups decide they want to work together:

A consignment agreement is made when both parties have something to offer to the entire process. Also, because it is a great opportunity to create commercial alliances. At the end of the day, they should know that they have to work as a team.

After making an agreement, only the possession of goods is transferred from one part (consignor) to the other part (consignee). This means that the consignor is still the owner of said goods. Also, the consignor is still responsible of their expenses.

The relationship of both parties is not of buyer and seller; it is of Principal and Agent. This is important to take into consideration because both have to work as partners and not competitors. They work together to achieve a certain goal together, too.

Moving forward; the consignor uses a Pro-Forma Invoice, a preliminary bill of sale, describing a shipment of goods in advance of its delivery.

Then, the consignee sends Account Sales, statements of the price the goods are sold at, commissions earned, expenses and net balance back to the consignor.

This overview helps us understanding inventory consignment process better.

Objectives for Inventory Consignment Process

What could we achieve with this process?

To start off, consignment comes in handy to have the following objectives or goals in mind.

It all mostly depends on the skillset, resources and experience we offer to the team. Some of the achievable objectives include:

- Attracting customers to increase sales volume. Because the consignee, ideally, already has a steady flow of customers, it could mean some of those customers will get to know the consignor too.

- Launching a new product and having a market for it. Also, breaking into a new market would be easier with the help of the consignee; being a part of it already.

- Getting higher revenue in a different geographical area; because they are two groups working for the same goal and they can reach different areas with the same product.

- Expanding the business to bigger markets; this could also depend on the business particularly. Put simply, it means that the consignor would have access to the consignee’s reach in the field.

- Sustainability in the market. Working together, both parties could support each other, giving them a better sustainment.

- Working with the talent and resources the consignee has to offer. In this case, the agreement is also an asset, because there is a part of it that actively provides the consignor with valuable and beneficial resources.

Of course, depending on your company, you can plan your own objectives. These are good examples of some goals you could achieve with this type of agreement, too. This is why understanding inventory consignment process is so important.

Inventory Consignment Process in Microsoft Dynamics 365

And finally, let’s talk about how Microsoft Dynamics 365 can improve the Inventory Consignment Process for your business.

Let’s take into consideration the process suggested by Microsoft; using their examples:

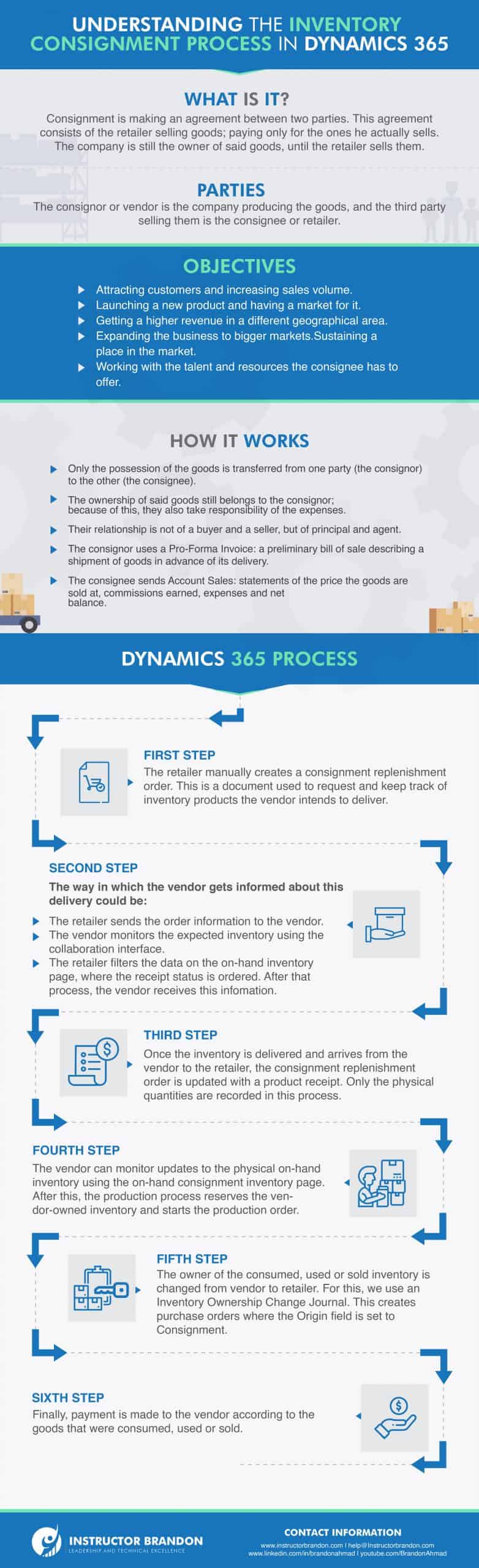

Step 1

First, the retailer manually creates a consignment replenishment order. This is a document used to request and keep track on inventory products the vendor intends to deliver. This is usually based on the forecast and demand of those products.

Step 2

The way the vendor gets informed about this delivery could be:

- The retailer sends the order information to the vendor.

- The vendor monitors the expect inventory using the collaboration interface.

- The retailer filters the data on the on-hand inventory page. Here, they order the receipt status. From there, the vendor receives this information.

Step 3

Once the inventory is delivered and arrives from the vendor to the retailer, the consignment replenishment order is updated. This, with a product receipt. However, only the physical quantities are recorded. They do not create general ledger transactions. This, because the vendor still owns the inventory.

Step 4

The vendor can then monitor updates to the physical on-hand inventory. They can do this using the on-hand consignment inventory page. After this, the production process reserves the vendor-owned inventory. Then, they start the production order.

Step 5

The ownership of the consumed, used or sold inventory changes, from vendor to retailer. For this, we use an Inventory Ownership Change Journal. This is used to record the transfer of ownership of consignment inventory. It goes from the vendor to the legal entity that’s consuming it.

This creates purchase orders where the Origin field is set to Consignment.

Step 6

After this, the vendor can monitor the consumption of the Products Received from Consignment Inventory Page. This allows him to issue an invoice based on the agreements between the parties.

This invoice processed is related to the purchase orders. Those are auto-generated when the Inventory Ownership Change Journal is processed.

Step 7

Finally, payment is made to the vendor according to the used, consumed, or sold goods.

As we have just seen, everything runs smoothly and is easier to manage with the help of Microsoft Dynamics 365 tools. Of course, it all depends on creating fair and productive partnerships. Also, thinking how beneficial it is for us (as a company) to work towards such agreements.

Outcome for the Inventory Consignment Process

This is our article about understanding inventory consignment process. Without a doubt, we in Instructor Brandon know how important it is in your business to carry out the correct process of inventory consignment of goods.

Since, being an asset of your property only as a loan for the client, you must keep things in order.

Definitely, Microsoft is innovating with its applications in the field of supply chain management. So, if you are interested, you can investigate more about the courses offered in these fields.

This will help you boost your career and your business. Do not hesitate to contact us if you have any questions. The truth is that new technologies are appearing. Microsoft is a standard in carrying them out. Don’t be left behind!

5123

5123

Hi Mr. Brandon, A very nice article on explaining the business need for consignment inventory and solution in Dynamics 365. Could you suggest, how can we process the vendor return for inventory having ownership with Vendor i.e. process return before changing the ownership.

Regards

Pradeep