Dynamics 365 Tutorials, Supply Chain and Logistics Management

D365 Inventory Blocking: Smart Practices for Quality Control

Improve Inventory Management with Inventory Blocking in D365

Inventory Blocking | Feature Management | Transfer Orders | Sales Orders | Production Orders | Sampling Plan

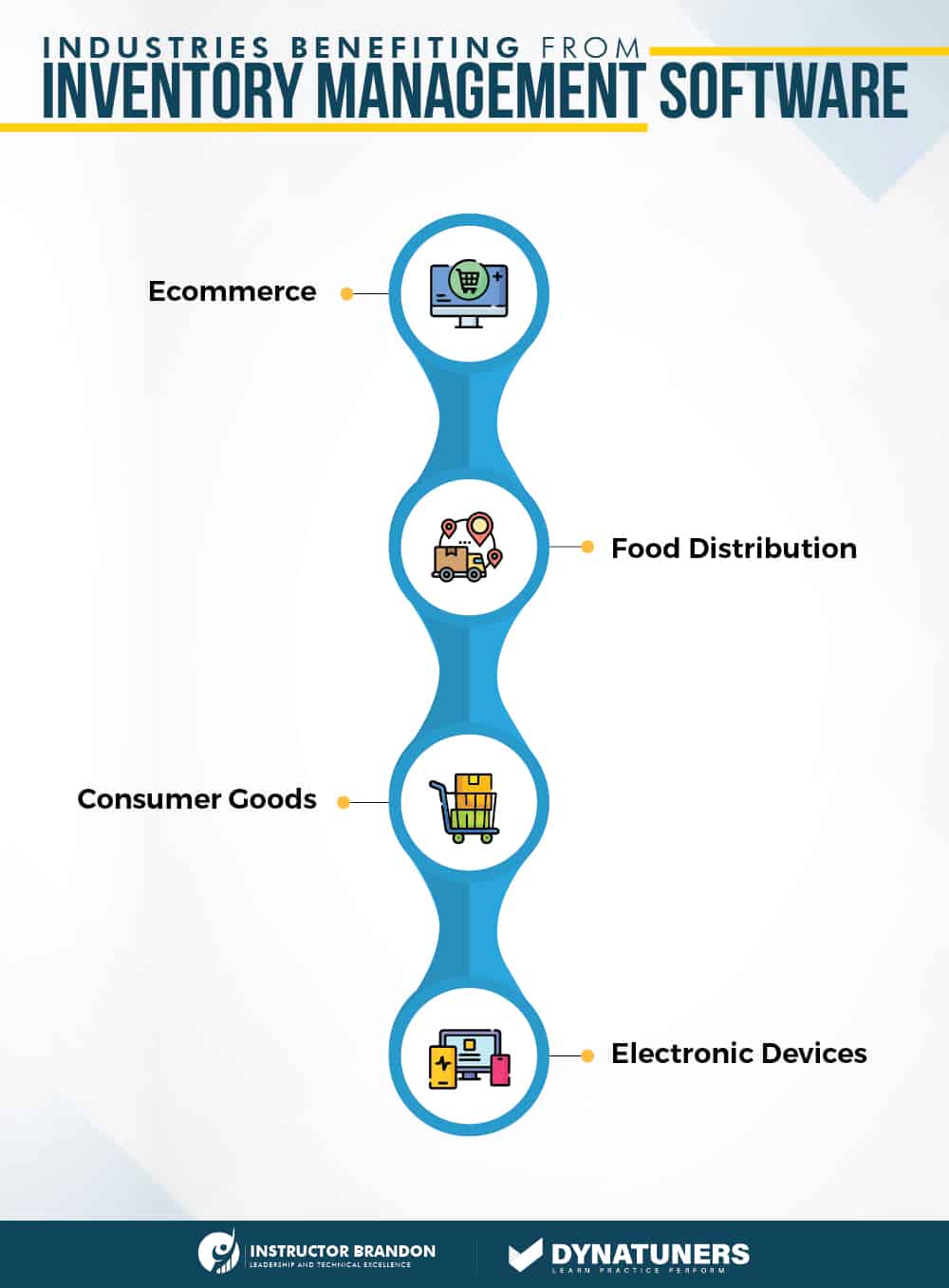

Inventory management is a critical component of every business plan. Keeping a close eye on inventory movement may make or break a firm, which is why entrepreneurs usually emphasize the need for proper inventory management. While some business owners understand the need of regular inventory management, others do not, enabling their company to slip through unforeseen gaps. Physical inventory cannot be overstated, much more so for ecommerce and online retail enterprises. Managing inventory and accurate monitoring enables firms to respond quickly and correctly to customer demands. Inventory management in organizations must increase in lockstep with the company’s growth.

Blocking inventory is a necessary step in the quality inspection process. Items are immediately banned from consumption or distribution during the quality check. Additionally, you may manually restrict goods from being issued or eaten. There are various techniques for blocking inventory items, but you may block them in one of three ways.

- Manually

- By creating a high-quality order

- By using a procedure that results in a high-quality order

- Manually block objects

Inventory Blocking Form

By initiating a transaction in the Inventory blocking form, you may restrict the amount of an item. For example, only goods that are currently in stock may be banned.

You must decide whether anticipated revenues should be included as an expected on-hand quantity in planning activities for manually blocked amounts. Anticipated receipts have been prohibited but are expected to become available as on-hand inventory after inspection. The Expected receipts check box is checked for products stopped by a quality order by default.

By removing the transaction in the Inventory blocking form, you may cancel a manually blocked amount.

Now by establishing a high-quality order, you may block items.

By generating a quality order in the Quality orders form. When you create a quality order, the quantity specified for an item is restricted.

Inventory blocking is a critical technique for quality control since it may prohibit utilization and signal the need for inspection. The warehouse management capabilities allow a variety of inventory blocking strategies, including the usage of quality orders and a blocked Inventory Status value.

Approaches to Inventory Blocking

Inventory blocking is a critical technique for quality inspection and control since it may prohibit utilization and signal the need for inspection. One method of inventory blocking is to use a blocked Inventory Status value. For example, a strategy might be based on quality orders, which often correlate with Inventory Status data. Each method generates an item on the Inventory Blocking form, together with details on the blocking source, and the information may be used as a quality management coordination tool. This technique represents a blocked Inventory Status Value that may be issued at the moment of order reception or a later date. The blocking is shown on the Inventory Blocking form and may be undone only by changing the value to a non-blocked value.

The master scheduling algorithm treats the inventory as useless and non-nettable. Except for transfers, adjustments, cycle counts, vendor returns, and the generation of a quality order, the blocking inhibits most inventory operations. A blocked value may be modified through a quality order or directly modified (via a client or mobile device transaction). Additionally, a blocked value may be associated with a subset of batch numbers or a particular serial numbers.

Blocking Inventory Based On a Quality Order

This strategy represents a high-quality order with “complete blocking” as part of the item sampling procedures. Manually establish a quality order for an item’s specified inventory, including inventory that has already been given a blocked value for Inventory Status. Alternatively, a quality order for an item may be produced automatically based on rules set on the Quality Association form, such as when a purchase order arrives or when the final quantity for a manufacturing order is reported. You may optionally write a description and comments regarding blocking associated with a qualifying order using the Inventory Blocking form.

SUMMARY

Inventory blocking is a mandatory step in the quality inspection process. During the quality inspection, items are instantly prohibited from consumption or distribution. For instance, only commodities presently in stock may be prohibited. Blocking inventory is a critical quality control approach since it signals the necessity for inspection. Utilizing a blocked Inventory Status value as a form of inventory blocking is one technique. Another technique might be focused on customer satisfaction, which often correlates with Inventory Status data.

Create and Maintain an Inventory Blocking in D365

Block inventory

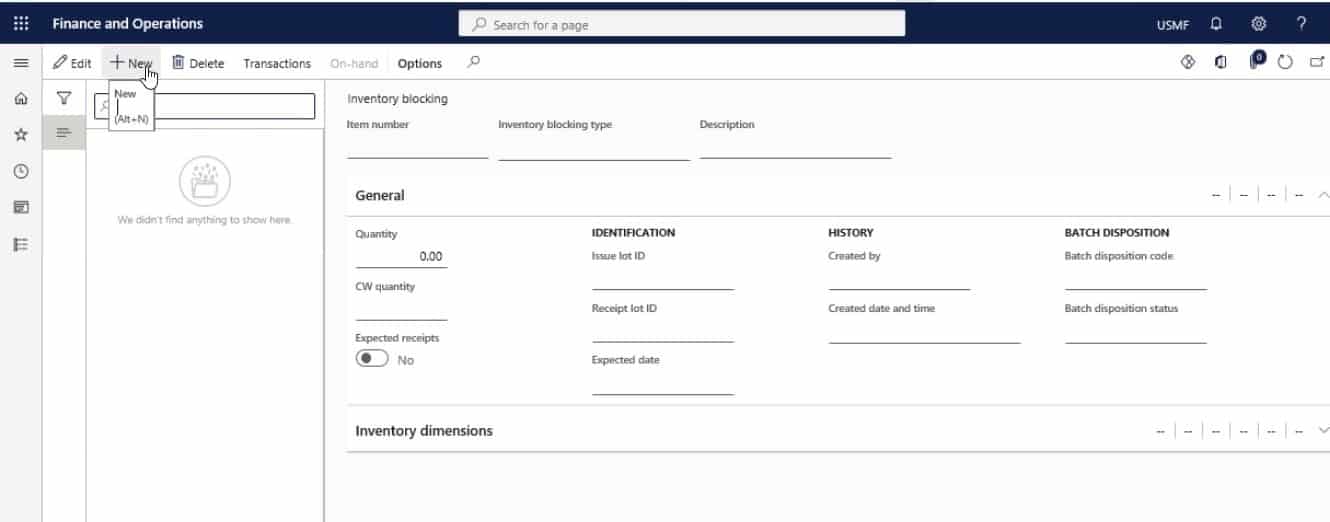

To create an inventory blocking record so that inventory is blocked, follow these steps.

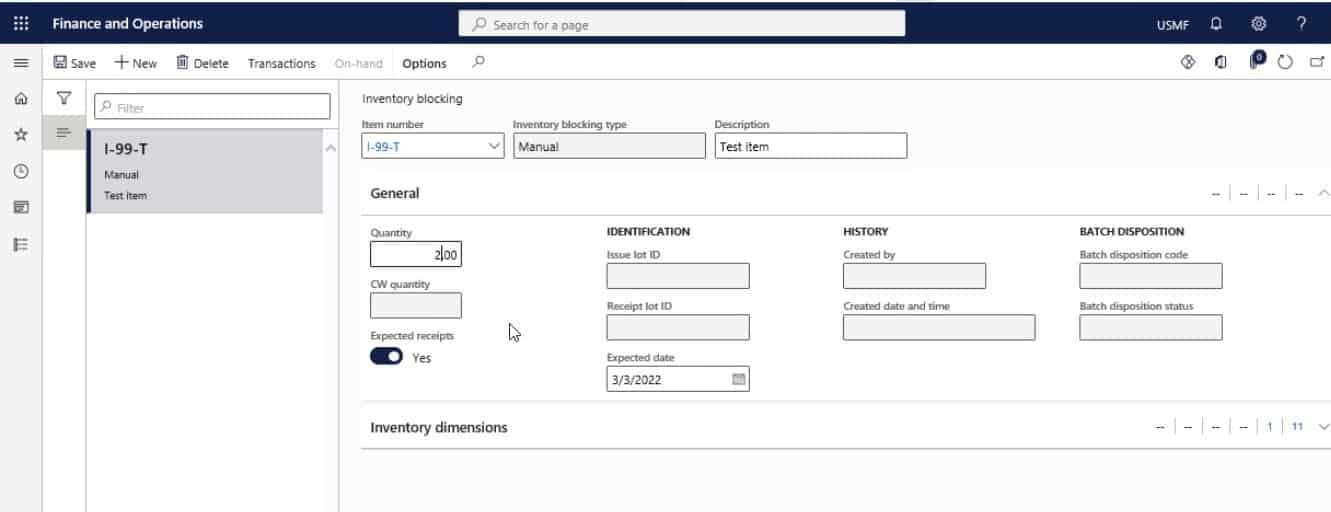

Step 1

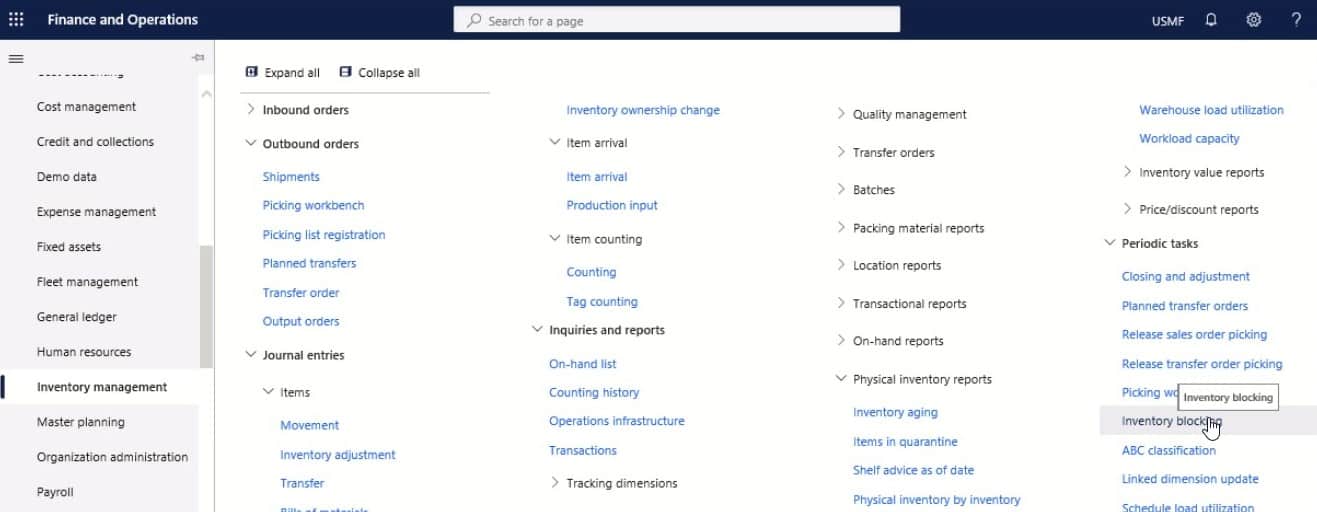

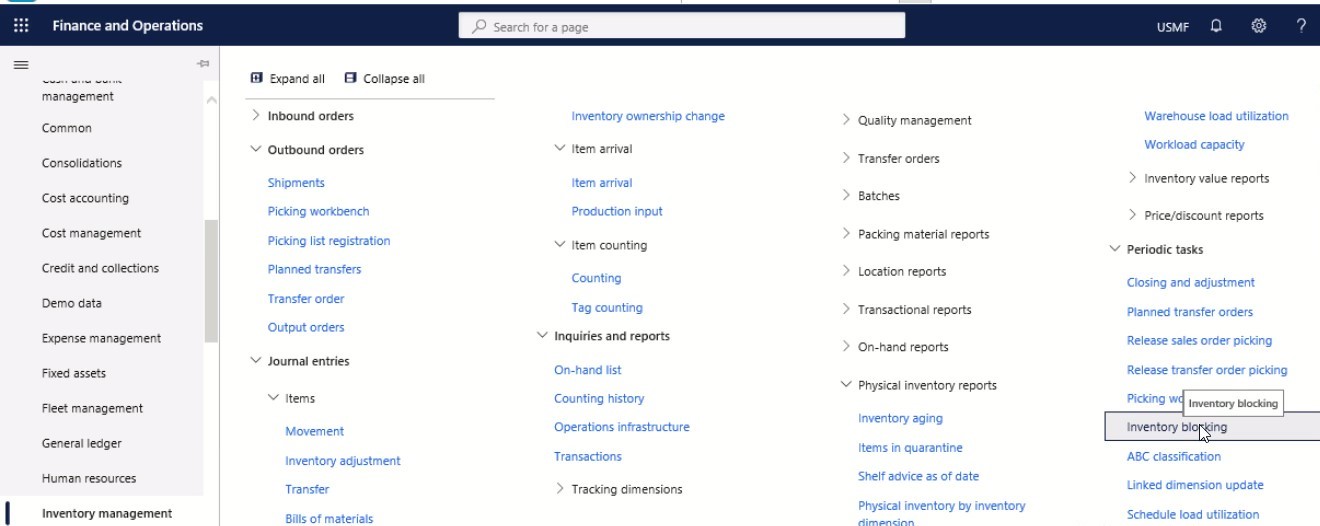

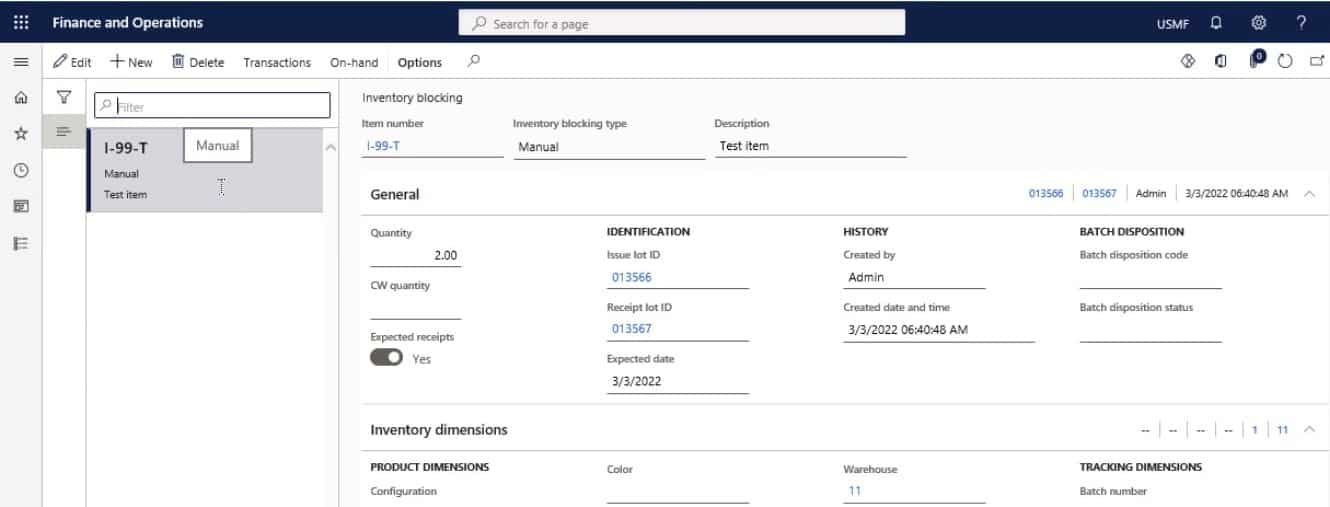

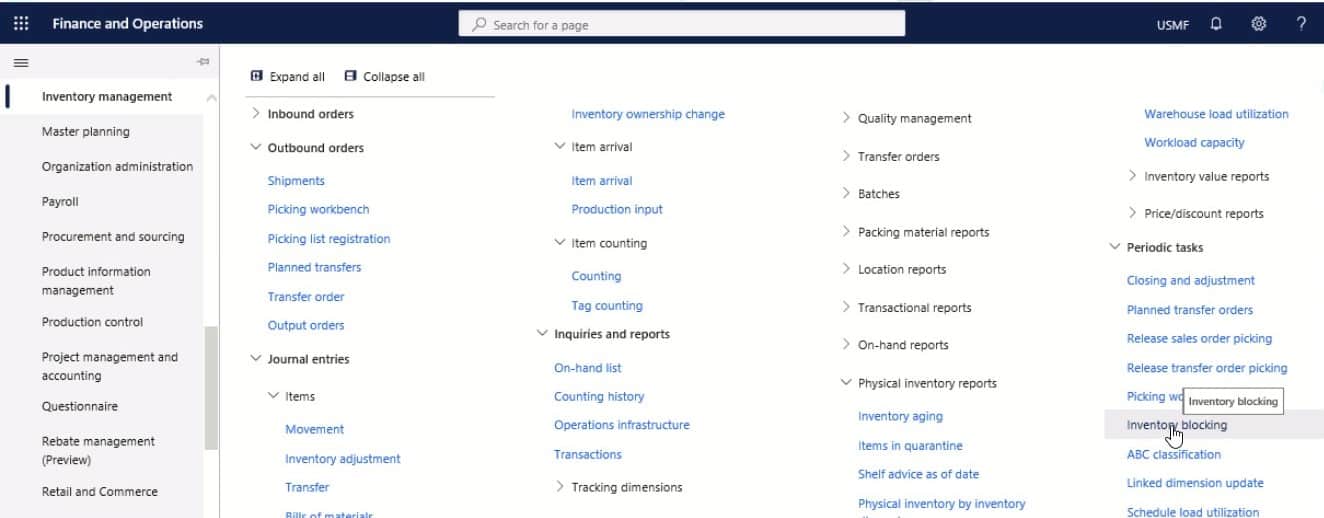

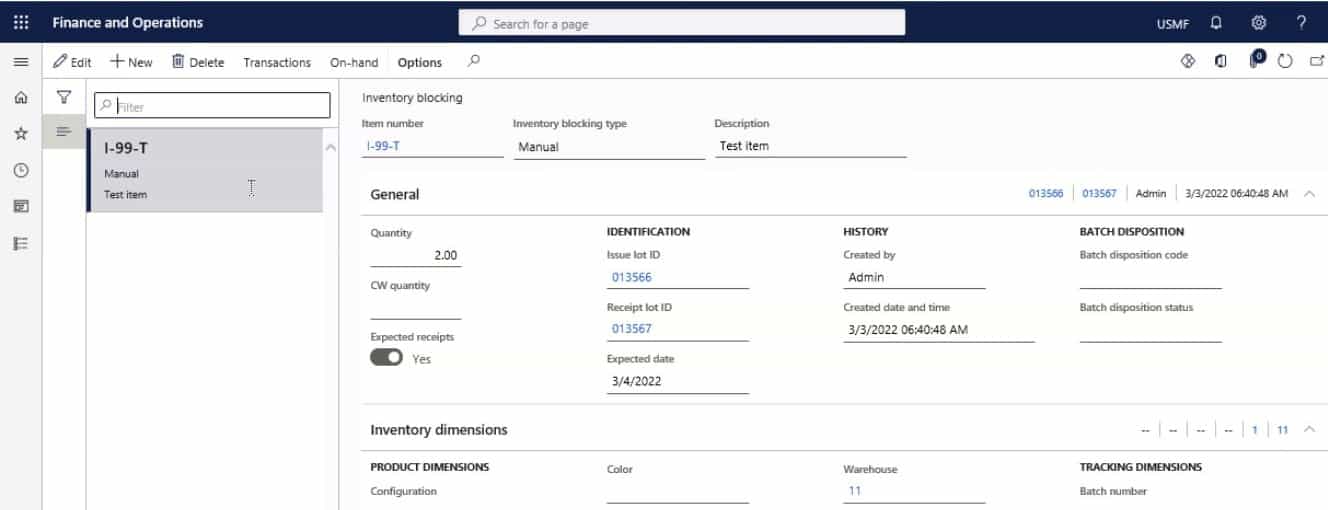

Go to Inventory management > Periodic tasks > Inventory blocking.

Step 2

On the Action Pane, select New.

Step 3

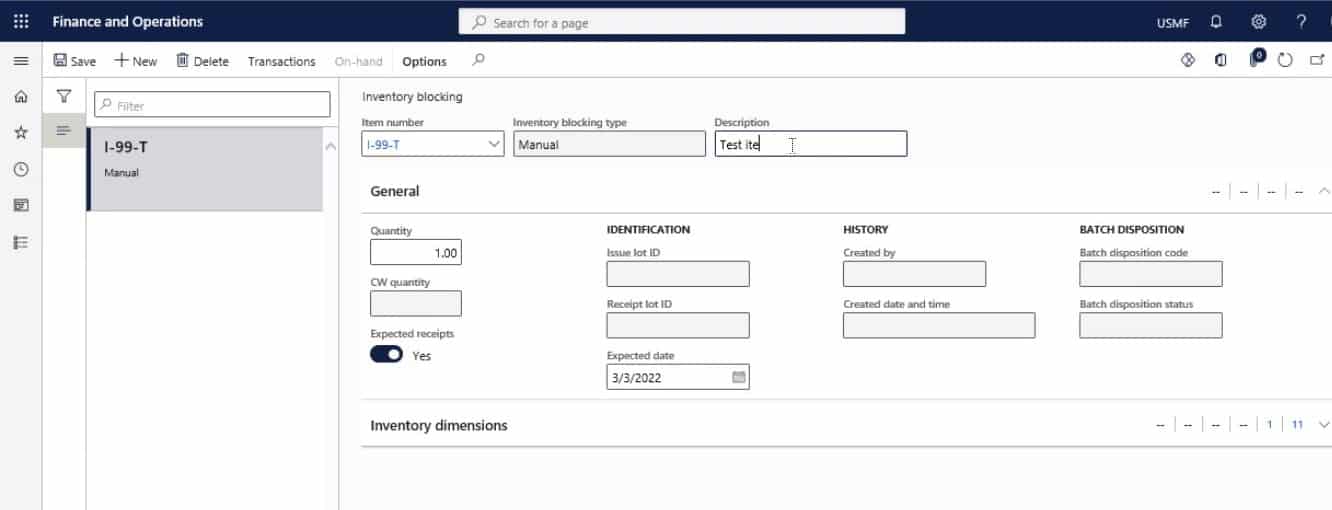

On the new blocking record header, provide a description and set the Item number field to the item you wish to block.

Step 4

Now On the General FastTab, in the Quantity field, enter the number of items to block.

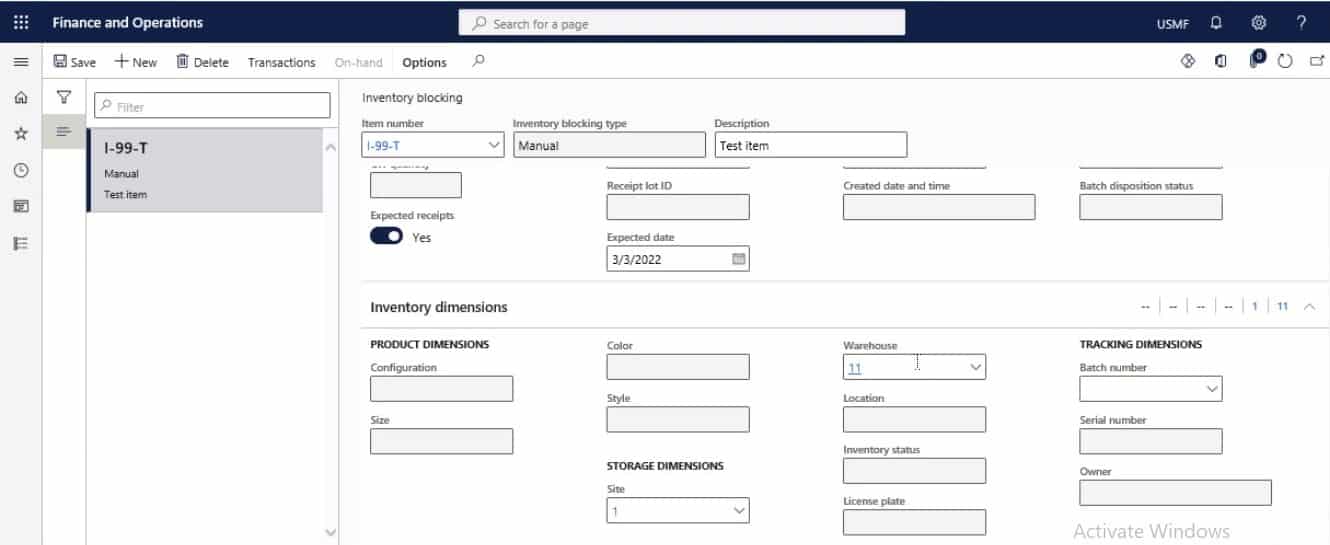

Step 5

On the Inventory dimensions FastTab, specify the site and warehouse where the items you want to block are currently located.

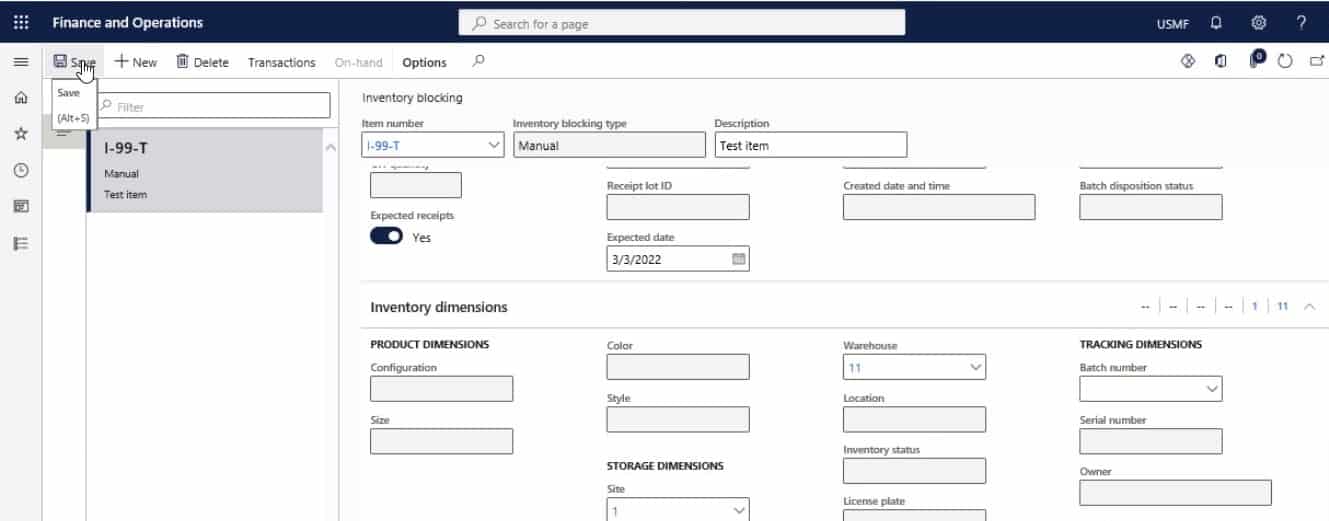

Step 6

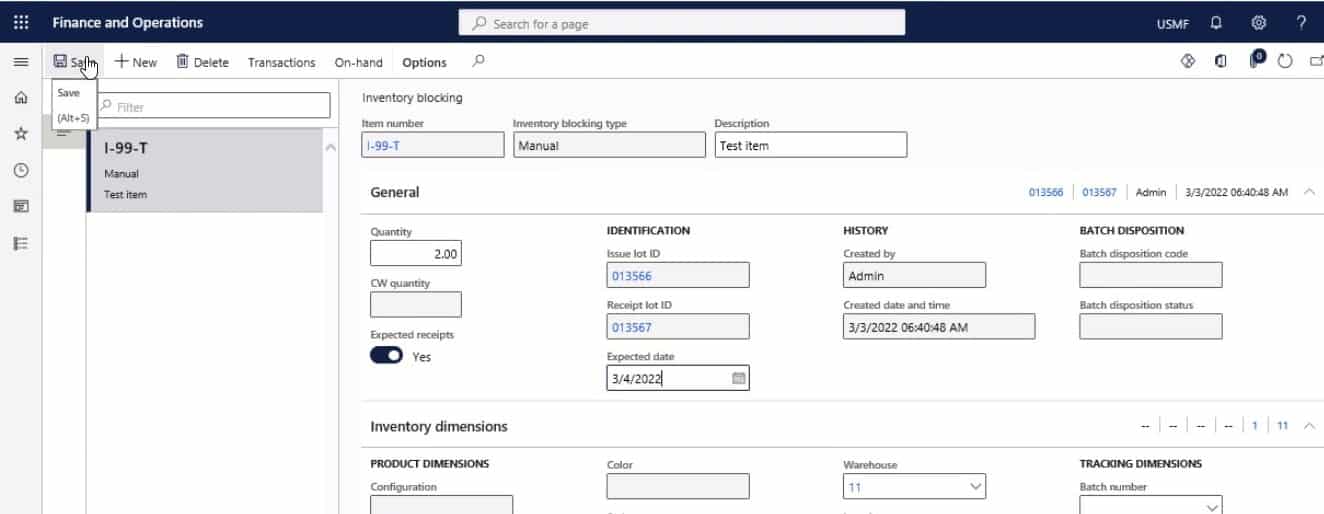

On the Action Pane, select Save.

To update an inventory blocking record, follow these steps.

Step 1

Go to Inventory management > Periodic tasks > Inventory blocking.

Step 2

In the list pane, select the relevant blocking record.

Step 3

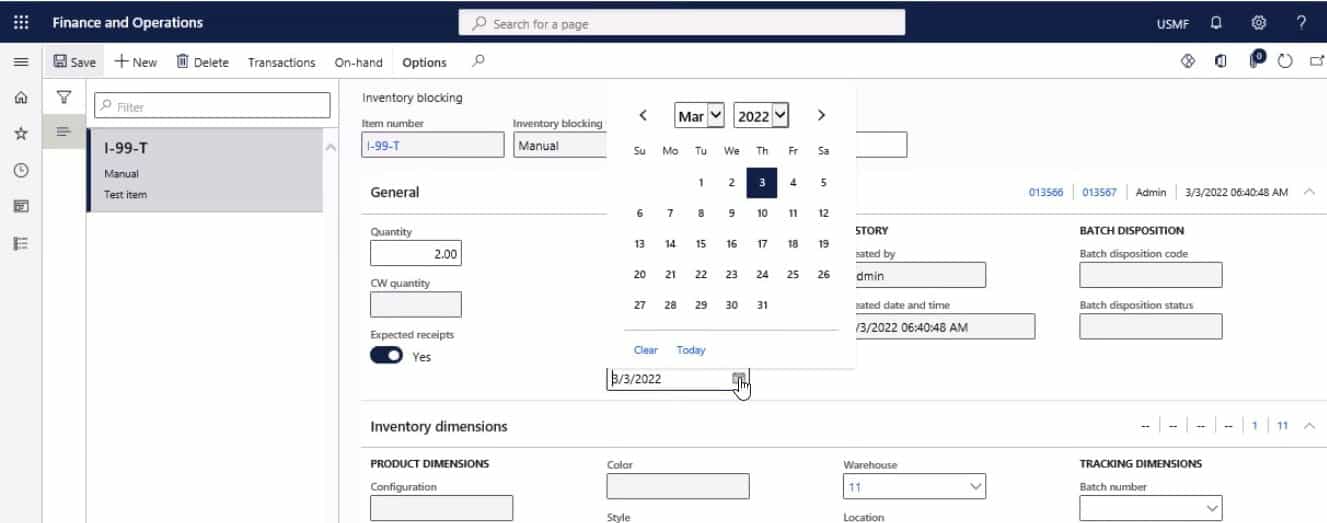

Edit the record as required.

Step 4

On the Action Pane, select Save.

Follow these steps to remove an inventory blocking record so that inventory is unblocked.

Step 1

Go to Inventory management > Periodic tasks > Inventory blocking.

Step 2

In the list pane, select the relevant blocking record.

Step 3

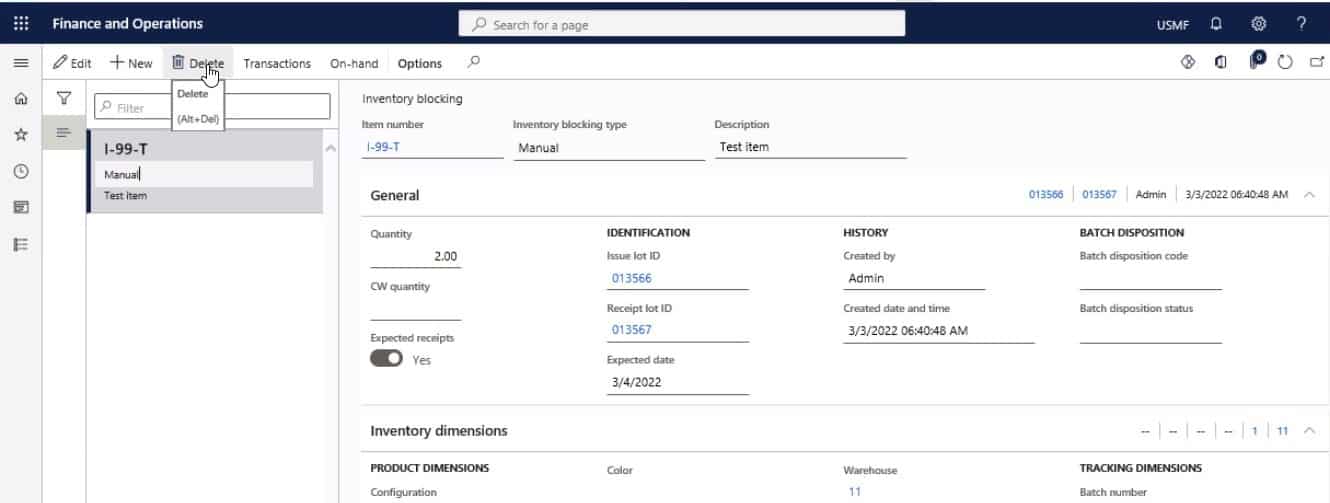

On the Action Pane, select Delete.

Step 4

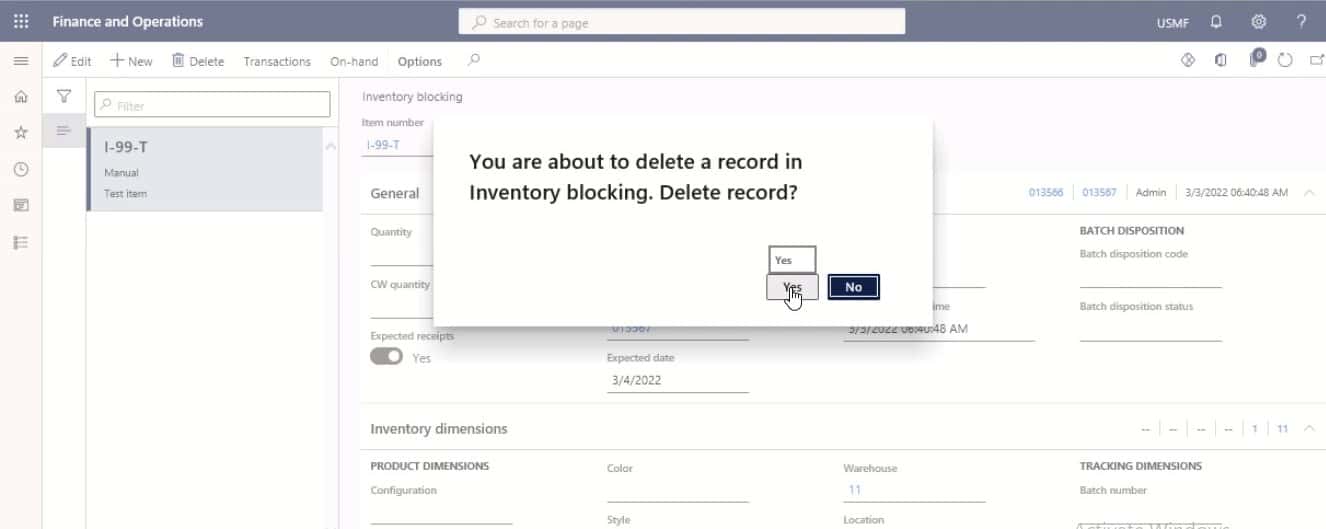

You’re prompted to confirm the operation. Select Yes to continue.

Step 5

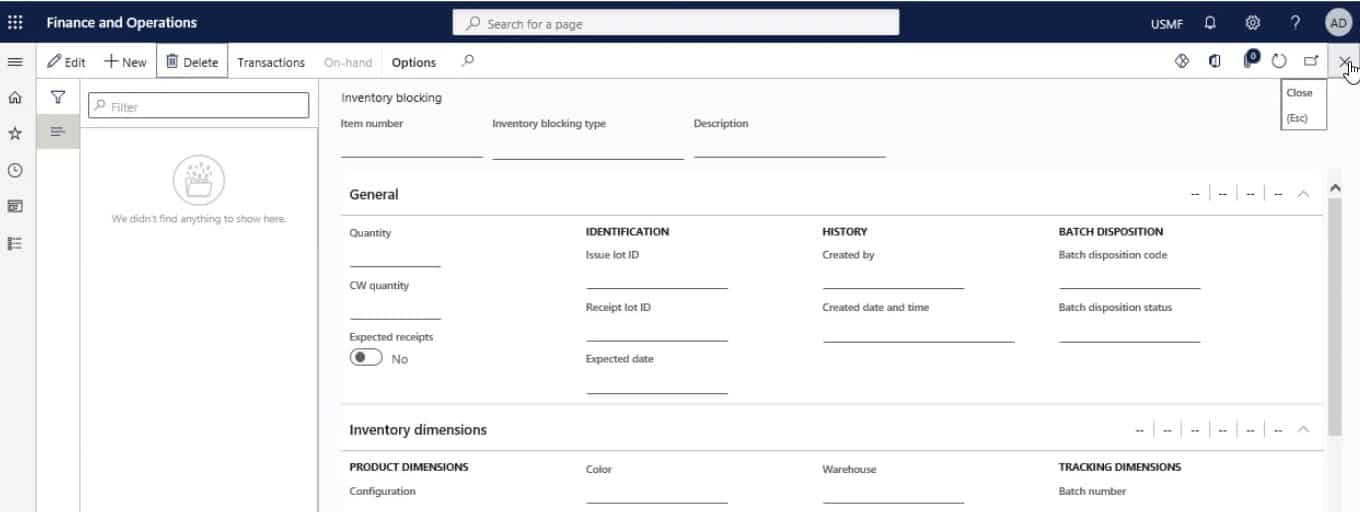

Close the page.

SUMMARY

Following the above steps you will be able to create and maintain block inventory in Dynamics 365.

Inventory Management Significance and its Tools

Inventory management is a critical aspect of building your online business. Indeed, when your order volume increases and you enter new sales channels and territory, controlling your operations manually becomes almost impossible. For instance, are you now required to log in and out of each of your several selling channels in order to display and process orders? And are you continually manually updating your stock levels on each platform after a sale?

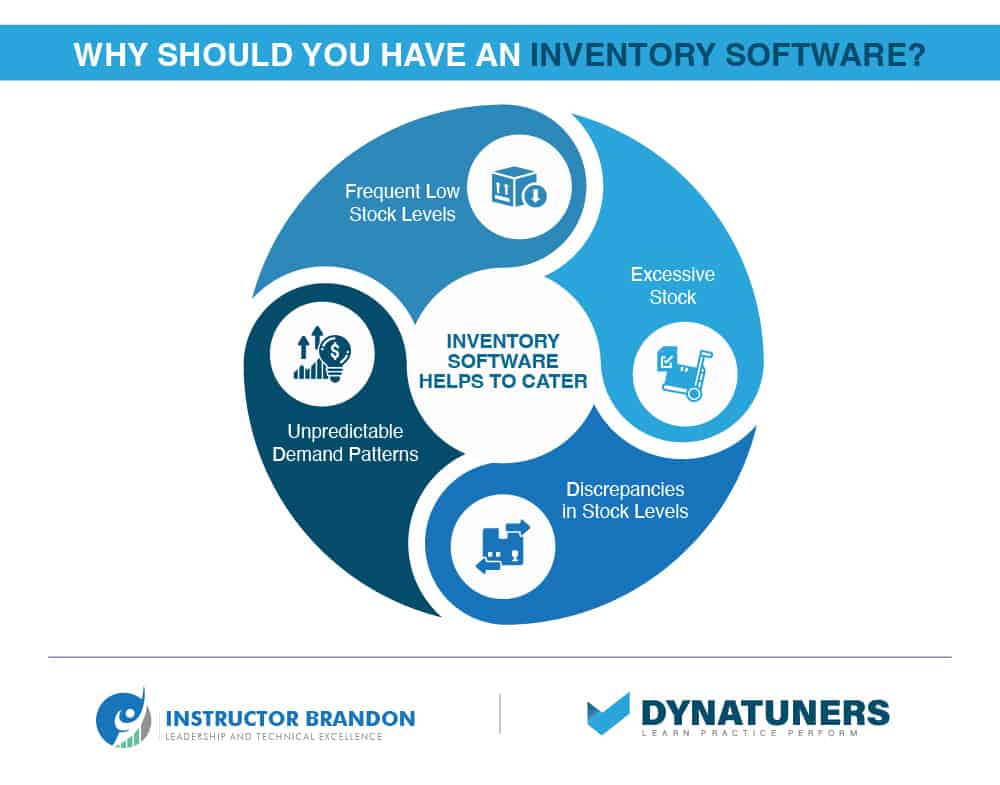

Not only do they obstruct business progress, but they almost always result in human error, such as overselling, which leads in a damaged image at best and market suspension at worst. While this alone highlights the crucial significance of inventory management, it is far from the sole reason to have one. To help you decide if your business may benefit from inventory management software, we’ve given a list of additional advantages below.

Inventory management simplified

Perhaps the most major benefit of inventory management software is that it streamlines the inventory management process, saving you time, money, and, quite simply, sanity. With supply and demand fluctuating throughout the year and your stock levels fluctuating frequently, inventory management software automates important business processes to help you avoid human errors.

Reduced likelihood of overselling

Overselling is a serious concern for online retailers, often resulting in a loss of control, dissatisfied customers, and, in some circumstances, suspension from marketplaces such as Amazon and eBay. Having said that, it is a preventable marketing stumbling block. How? By synchronizing your orders and inventory across all of your online marketplaces and ecommerce platforms, you can guarantee that stock levels are updated after each transaction. While this is often easier said than done, you can see how Rinkit, a home and garden retailer, overcome this hurdle and grew abroad.

Cost savings

By streamlining your inventory management procedures, you may reduce the inventory costs associated with human error and realize significant cost savings. What are these cost-cutting strategies for inventories, then? To begin, it improves your prospects of lowering supplier lead times by fostering stronger supplier management relationships. Additionally, by setting par levels and calculating safety stock, it helps you to remove excess and obsolete stock and related expenditures. However, this is not all. Perhaps the most cost-effective approach of cost reduction is automation. Inventory management issues such as stock-outs and excess inventory may result in significant revenue losses.

Avoiding stock-outs and excessive inventory

This is a difficult topic in inventory management. After all, an inadequate inventory level might result in a stock-out, dissatisfied consumers, and potential revenue loss. On the other side, excess inventory may take up valuable storage space and result in unnecessary costs. In either event, it will cost your business. Stock control inventory management software, on the other hand, helps you to monitor low stock levels and identify reorder points for particular goods, therefore reducing stock-outs. More exactly, this kind of software will be capable of computing these reorder points – also referred to as par levels – through a reorder point algorithm.

Improved business negotiations

By using inventory and order management software that incorporates batch tracking capabilities, you may significantly increase product traceability and get access to critical information for prospective supplier negotiations. This will give you a far more clear view of which providers contribute the most to your organization’s success.

Increased product exposure in the event of a recall

At times, recalls of products are inevitable. However, in the absence of batch tracking capabilities, the problem is the time and effort necessary to discover afflicted items. Indeed, without perfect product traceability and the ability to locate necessary batches quickly, fixing a problem with your supplier may be rather challenging. Effective inventory management software may provide critical sales data, allowing businesses to make data-driven decisions. For example, by improving your understanding of supply and demand, you can forecast sales trends and acquire a competitive edge.

Numerous inventory management solutions empower you to make strategic decisions by providing you with access to reporting tools and inventory indicators. Additionally, by measuring your inventory turnover rate, you may be able to identify opportunities to minimize the amount of inventory maintained in your warehouse(s) and thereby lower your inventory carrying costs. Want to read on transportation management? Click here.

SUMMARY

Inventory management is a vital component of successfully growing an online company. It simplifies inventory management, saving you time, money, and sanity. A low inventory level might result in a stock-out, disgruntled customers, and even revenue loss. Improved supply and demand awareness enables you to foresee sales trends and maintain a competitive advantage.

Why Inventory Management Skills in Supply Chains Are Critical

Inventory management is a sometimes ignored yet critical component of supply chain management. Inventory management expertise is a vital component of a supply chain manager’s fundamental abilities.

|

Sr. |

Critical KPIs for Inventory Management | |

| KPI | Description | |

|

1. |

Cost of Carrying Inventory | The percentage representing cents per dollar that is spent on inventory overhead each year.

Formula: Carrying cost / Overhead cost |

|

2. |

Average Inventory | The amount of inventory on-hand during a specific period of time.

Formula: (Beginning Inventory / Ending Inventory) / 2 |

|

3. |

On Time Orders | The percentage of the time that customers receive their orders on time.

Formula: No. of Orders Delivered On Time / Total No. of Orders |

There are many reasons businesses should seek a supply chain manager with strong inventory management capabilities: Inadequate inventory management may have ramifications across the firm and hurt the bottom line. For instance, if a hospital chain’s supply chain management fails to maintain an appropriate inventory of a critical medical product, such as syringes or personal protective equipment (PPE), the institution’s ability to offer medical services may suffer.

Additionally, excessive inventory and inventory tracking may be a big inventory management issue. Over ordering consumes cash, complicates warehouse inventory management, and may result in a loss due to an obsolete or expired product that the business cannot utilize or sell so managers need to be very careful about costs associated with excess inventory.

Consider the case of a supply chain manager for a clothes company that does not maintain a close eye on client demand. In such instances, the corporation may find excess inventory from a previous season that no merchant would order. If the firm sells these things on the discount market to recuperate part of its expenditures, the resulting oversupply of reduced products might hurt the brand’s reputation with customers and have a material effect on profit margins. On the other hand, effective inventory management skills may increase profitability, improve supply chain visibility, and streamline operations by maintaining a consistent inventory.

Consider the case of a supply chain manager for a clothes company that does not maintain a close eye on client demand. In such instances, the corporation may find excess inventory from a previous season that no merchant would order. If the firm sells these things on the discount market to recuperate part of its expenditures, the resulting oversupply of reduced products might hurt the brand’s reputation with customers and have a material effect on profit margins.

On the other hand, effective inventory management skills may increase profitability, improve supply chain visibility, and streamline operations by maintaining a consistent inventory flow. For today’s supply chain management, inventory optimization is the gold standard.

Here are some of the issues that supply chain managers have to deal with when managing inventory:

-

Inadequate Inventory forecasting

While no forecast is flawless, a lack of visibility into your supply chain’s inventory management makes it practically difficult to balance product supply and demand. Inventory waste and liquidity concerns are challenges that supply chain managers must solve via contemporary SKU monitoring and a heightened awareness of data from retail partners and distributors.

-

Distribution and sales throughout the product’s shelf life

Perhaps no other supply chain concern was more prominent in the minds of businesses, governments, and consumers than vaccine shelf life and expiry. Managers must understand consumer behavior and trends allows companies to better manage how much is ordered and produced at each supply chain step, with the objective of reducing waste. Do you want to learn more on how to handle consignment inventories, read our blogs.

-

Carrying expenses

These are incurred as a result of a warehousing scarcity. Despite severe headwinds for brick and mortar shops over the last year, e-commerce growth drives product demand across sectors. Managers must identify, assess, and then prioritize which expenses and risks to address first in order to reduce total supply chain risk.

SUMMARY

Inadequate inventory management may have a ripple effect across the organization, affecting the bottom line. Excessive inventory and monitoring of goods may be a significant inventory management concern. Inventory management effectively may boost profitability, enhance supply chain insight, and simplify operations. Inventory optimization is the gold standard in today’s supply chain management.

Final Remarks: Inventory Blocking

Numerous inventory management solutions are bringing AI to use. You can examine patterns in your logistics, raw material, and warehouse operations in near real-time, allowing for quick modifications to keep your supply chain moving. If you’re ready to take the next step in your profession, have a look at our most recent basic and certificate level courses.

Even with these advancements in contemporary supply chain management, global supply networks complicate inventory control on numerous levels. This emphasizes the critical nature of inventory management in supply chain planning. Given the logistical and financial constraints encountered over the last year, businesses must do a better job emphasizing the discipline’s value. Fortunately, efforts to use artificial intelligence and machine learning strengthen inventory management systems, enabling supply chain managers to meet the rising demand for manufacturing and delivery speed. Given the critical nature of a responsive and agile supply chain, the COVID-19 pandemic’s irregular demand fluctuation erased them. Therefore, developing a responsive and agile supply chain is essential for today’s supply networks, as is developing benchmark inventory management competence where it is required.

SUMMARY

By monitoring trends in your logistics, raw material, and warehouse operations in near real time, you can make immediate adjustments to keep your supply chain flowing. By using predictive analytics you can uncover inventory patterns today and adjust your business goals accordingly.

At Instructor Brandon | Dynatuners, we always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you’re interested to consult with our specialists on how it may benefit you to achieve transparency in business processes, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is inventory blocking and how does it work? ” answer-0=”Inventory blocking essentially means preventing items from being processed or consumed. There are multiple ways to block inventory items, such as manually, by creating a quality order, by using a process that generates a quality order and by using inventory status blocking ” image-0=”” headline-1=”h2″ question-1=”What causes supply chain bottlenecks? ” answer-1=”A bottleneck arises when workloads come at a rate that exceeds the capacity of the production system (such as an assembly line or a computer network). Several typical bottleneck contributors include inefficient storage techniques, poorly planned operational procedures, imprecise inventory standards, restricted resource networks, inefficient labor, a lack of supply chain transparency, and demand-supply gaps. ” image-1=”” headline-2=”h2″ question-2=”In Dynamics 365, how can I unblock inventory? ” answer-2=”To Manually unblock inventory items, you can select Inventory management > Periodic > Inventory blocking from the drop-down menu. Select the blocking transaction for the inventory goods you wish to unlock and remove it by clicking the Delete button or pressing ALT+F9. ” image-2=”” count=”3″ html=”true” css_class=””]

6447

6447